1

1

Sometimes the answer is not to cross an old bridge, nor to burn it, but to build a better bridge.

Sometimes the answer is not to cross an old bridge, nor to burn it, but to build a better bridge.

Need more info?

Ernie and Erica

Wood burning stoves, Rocket Mass Heaters, DIY,

Stove plans, Boat plans, General permiculture information, Arts and crafts, Fire science, Find it at www.ernieanderica.info

Need more info?

Ernie and Erica

Wood burning stoves, Rocket Mass Heaters, DIY,

Stove plans, Boat plans, General permiculture information, Arts and crafts, Fire science, Find it at www.ernieanderica.info

Ernie Wisner wrote:yes it has been hoed and planted and harvested. but like most things that can kill you. it needs careful stewards. For instance have you ever worked with live steam? have you ever done plumbing (not the connect pipe A to pipe b in this book but actual work on systems that are pressurized and if you get it wrong you get to try and shut it down while its spewing fluid at pressures that saw through 2X4's?) That sort of thing. Do you under stand the concept of dont put a valve in a system unless it is absolutely necessary cause some on WILL come shut it off Etc.

Need more info?

Ernie and Erica

Wood burning stoves, Rocket Mass Heaters, DIY,

Stove plans, Boat plans, General permiculture information, Arts and crafts, Fire science, Find it at www.ernieanderica.info

1

1

Need more info?

Ernie and Erica

Wood burning stoves, Rocket Mass Heaters, DIY,

Stove plans, Boat plans, General permiculture information, Arts and crafts, Fire science, Find it at www.ernieanderica.info

POSTSCRIPT: :

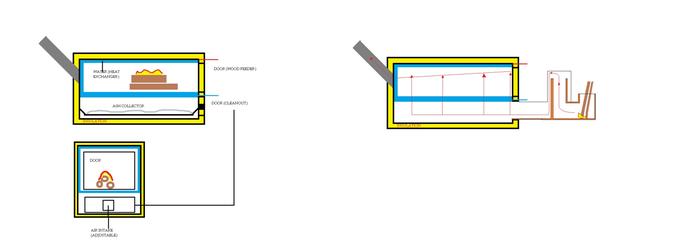

POSTSCRIPT: : Am thinking about stacking on a gasification chamber, and for now, channeling the possible wood gas produced back in to the combustion chamber. Think it might work? Also, copper coils around the gasification unit will serve to reclaim its heat, and serve as a "pre-heater" for the boiler make-up water. Am going to instrument all of this eventually, with pressure and temperature gages. For now, am using a "Sears" multimeter with "IR" function and "K" remote sensors.

Am thinking about stacking on a gasification chamber, and for now, channeling the possible wood gas produced back in to the combustion chamber. Think it might work? Also, copper coils around the gasification unit will serve to reclaim its heat, and serve as a "pre-heater" for the boiler make-up water. Am going to instrument all of this eventually, with pressure and temperature gages. For now, am using a "Sears" multimeter with "IR" function and "K" remote sensors.

Nothing is impossible

|

money grubbing section goes here:

Our PIE page has been updated, anybody wanna test?

https://permies.com/t/369340/PIE-page-updated-wanna-test

|