Sky Huddleston wrote:

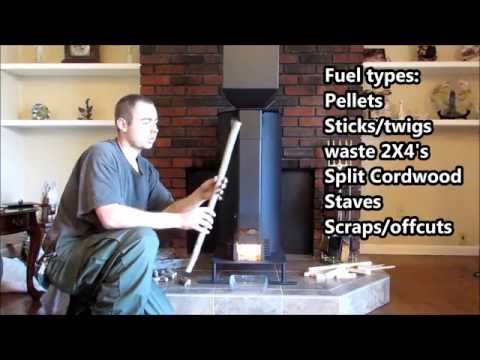

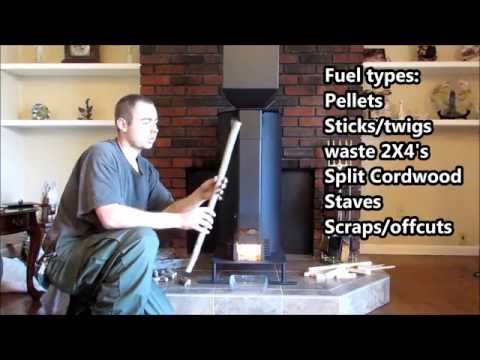

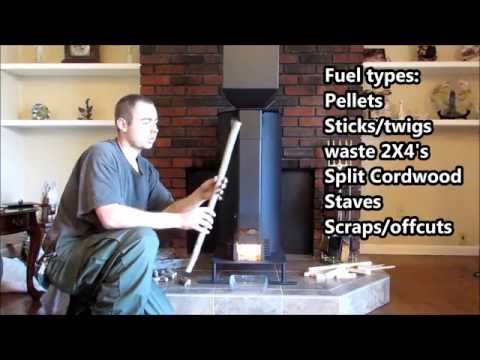

^Our rocket heater can also burn wood, too. So you are not tied to pellets. You can burn free fuel in the form of sticks and waste during the day, and pellets when you are gone and for overnight. This extreme versatility is something no other commercial pellet or wood stove can offer.

I read the entire thread (whew) and have one question. Sky, you said it would burn waste, and the video of the guy "testing" showed he fed in coal and even a duraflame log down the regular feed tube. I am thinking your stove will burn darn near anything, including wood chips. Evidently most pellet stoves will not burn chips, due to the auger feeds, but it looks like anything you put into the hopper will drop down into the burn chamber and get consumed. In our situation, for at least this one winter, which is fast approaching, where we will be living in two RVs inside an 1800 sf presently uninsulated pole barn in Minnesota, where temps can get to sub zero I'm told, we will likely be burning 24-7. So instead of buying pellets for $dollar$, couldn't one get a chipper and run some sticks through the chipper and then feed the chips into the hopper? This property has maybe 40 acres of wooded land that has been neglected for probably 20 years. Lots of usable wood in all sizes and states of decomposition.

We'll also be setting up a simple inefficient cast iron stove that we can throw logs in during the day, but it won't carry us through the night. We figure if we can keep the barn to 50 degrees or so, the propane heaters in the RVs can do the rest. This is a temporary fix for this winter only.

I am collecting bunch of more efficient ideas and plans, and will eventually be insulating the two pole barns - setting up my machine shop - rebuilding the 1860 something farmhouse - building more rocket stoves and waste oil heaters - and playing with other heating sources, but I'm told the first freeze could arrive as soon as September, (a few weeks away) so for this one winter, we are primarily concerned with, well, actually surviving our first winter here by heating this one barn. Fortunately we are still young and strong (71 and 73).

Hopefully pretty soon I will set up the sawmill I made and will get a lot of sawdust from that. Will be looking into making some sort of machine to reclaim that and press it into logs too. But that won't happen until we are set up in the barn. Priority one, don't freeze.

Sorry, I wandered off a bit, but wanted to give an idea of our situation. And yes, according to what I've gathered from this forum, we could just buy enough pellets to burn 24-7 for about $250 a month, which is not unreasonable. We could do that, but why not use what is free and at hand?