Ok so I have some 8'inch diameter pipe I am going to cut in half at a angle so I can simply put the two pieces together and then weld her shut resulting in a 90 degree angle as depicted

here with a lil' bit of a gap to get the point across..

I imagine this will be just as efficient if not more so than a 90 degree curve like this

I am going to make the gap where the heat rises out of the Jtube to the top of the barrel 3 inches for plenty of air flow the rest of the system will consist of used stovepipe no less than 8'in in diameter to keep the air flow going.

Since my 8 inch pipe is 1/4 thick I am not going to use firebrick I think that should prove to be plenty of insulation and will save $2.49 a brick for about 75$ worth in savings cheapest I could find around here few stores near me stock any, I am still going to use a much cheaper brick maybe broke up cinder blocks which I have a few of and some mason's sand and some clay.

my barrel length is 36 1/2 inches and my pipe is 8 inches at the bottom and you get 8+36 1/2= 44 1/2 for the length of the pipe going up into the barrel I have read that my ground pipe should be half the size of that so 22 1/4 can I make this 11 inches without any negative impact on heat/draw?

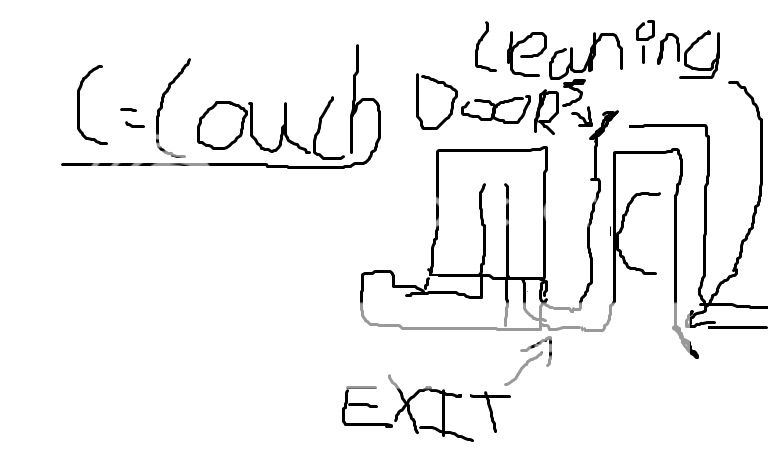

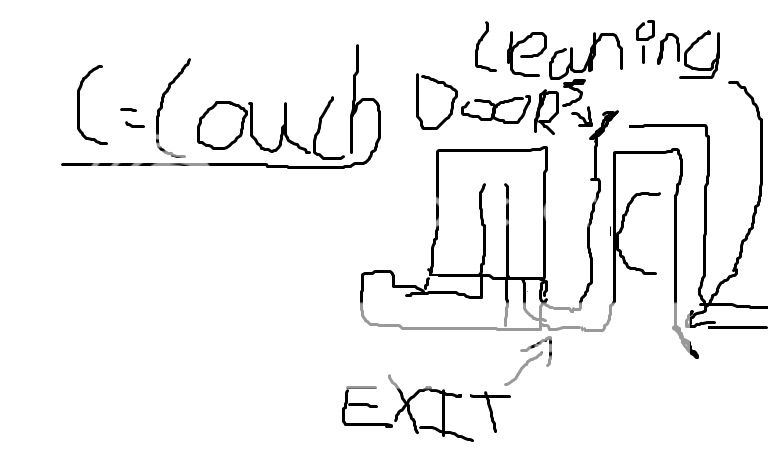

The barrel will have a detachable lid for easier cleaning I am also going to try and make little metal cleaning doors with hinges and a anchor for the door to stay put in the clay probably too much work but it'd be nice come cleaning time instead of taking a hammer to my clay to get access to it.

This drawing would be for the hot air leaving the barrel and heating the stove-pipes which I would then build a couch over.

I am thinking about for my feed area instead of just making it brick making it out of metal and have a metal drawer with a insulated knob that would slide out and sever as my ash catcher and I would like to have this 2 inches below my 8inch diameter start of the jtube. Also up near the top have a metal damper to open and close to allow for extra air in case my log is plugging the entrance or I feel the stove just isn't getting the right amount of air. Would this metal section get really hot or would the air cool it down enough where it wouldn't? Also it doesn't matter how deep I make my ash tray does it?

Also I'm thinking about extending the height of the vertical feed tube and putting a hinged door up top that I can close cutting off air from that area but keeping a well placed mid section damper near where the fire would be going to keep the fire going but eliminate any threat of a fire crawling out the top maybe put a few good drill holes in it to keep a little bit of draft going through to get rid of any nasty smoke buildup.

Ok I think that covers it wew I think i'll do a nice video of how I made mine just for good internet karma.