allen lumley wrote:Rick Lawrence :I find that I like your idea a lot,

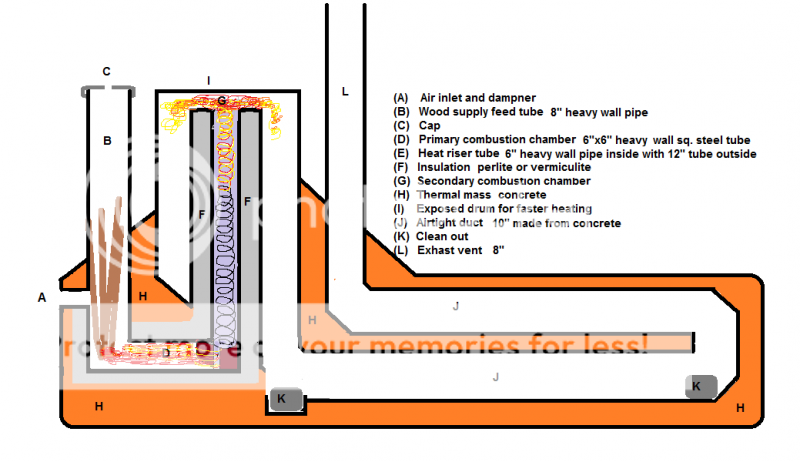

I hope you have a little more extra slop in your 10 inch pipe then is shown in your sketch, or can trim a little thinner, Your Firebrick will expand ! Some room for

expansion must be allowed for !

Arlyn Gale wrote:Allen - yes, the staggered mortar joint makes the alternate courses interesting. A square outside/octagon inside, such as PvdB documents, addresses that issue.

allen lumley wrote:

Late note : Rick, while probably not idea you can create an interesting spiral to stagger your mortar joint lines, this will increase turbulence and may or may not help

complete combustion ! A.L.

Arlyn Gale wrote:[quote=Rick Lawrence "Did you read my post at all? Like it says 2" firebrick cut at 22 1/2 degrees 3 7/8" long."

If you cut 2" bricks per your diagram, they won't fit in a 10" pipe without further trimming, and, perhaps more importantly, will only give you a 5-3/8" (inside) octagon.

[/b]For a 6" (inside) octagon, 2" brick should be cut (@22.5*) 4-1/8"(long) [/b]. The outer octagon would be 10".

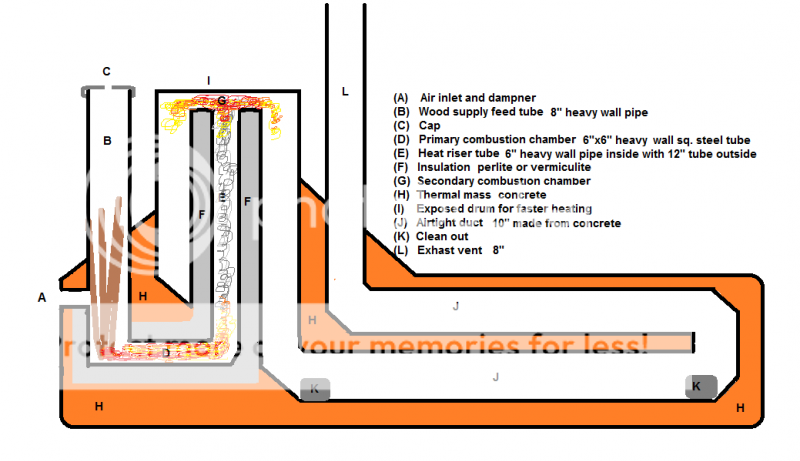

allen lumley wrote:Speaking as an old cheapskate, I have no problems with building an RMH with what comes to hand, Ideally the floor of the combustion core should have

some hard dense fire brick for durability,and a case can be made for including them in the heat riser to promote a good strong draft and easy relighting

Having said that the less mass to absorb the heat the more of the heat energy that will be reflected back into the combustion zone, the quicker it will come

up to temperature and the Cleaner the total burn will be!

Arlyn Gale wrote:According to my new friend - http://www.pagetutor.com/octagon_layout/ , you'd have to trim the outside tips of 2" brick a bit to fit into a 10" pipe. (Perfect cuts would require a minimum 10.75" ID pipe with untrimmed 2" bricks). From everything I've read, metal should hold up OK on the outside of the heat riser.