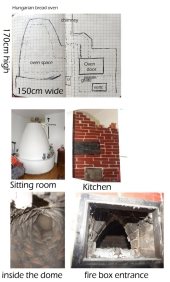

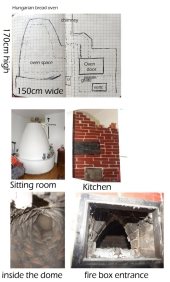

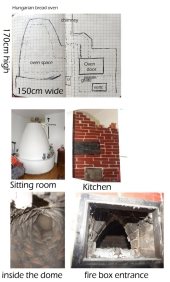

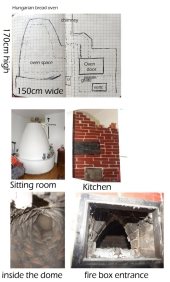

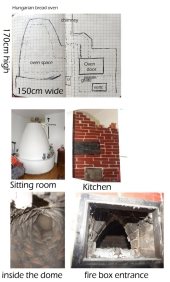

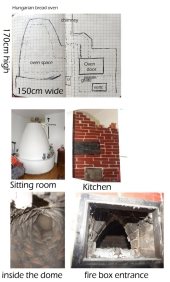

Thank you again for this assistance. To get things clear i live in an old east German circus wagon, that i have rebuilt myself, it is insulated with 60mm hemp throughout, a double skin of pine 40mm out side and 20mm skin of pine inside. The floor is 80mm of borox coated paper fluff with 30mm floorboards, the wagon is rated for 16tons and for the past four years the space has been comfortable helding up to the common -10 C. winter months here. I have been using an old Wamsler cooking range a bit like an AGA or Rayburn (no back boiler). The fact is that i wish to improve on the high emissions and fuel consumption. Having built many rocket stoves for outside kitchens i thought i would try out a rocket style design self build, good for confidence and to live by example. Well yes i do have a stove builder friend where i can get Ca-Si in most sizes. I have the current stove concept placed on a slab of Ca-Si. As for the max. foot print it could go as far as 70x150x120(W,L,H). the height of the wagon is 180 slanting up to 220, thus the riser center point would be roughly 2meters. The stove would run along the side of the wagon currently protected with glasswool in. and farmercell board to use the existing flue system, 120mm. would be nice but not necessary.

I hope that puts you in the picture. best wishes Antz