Hamza Rahy wrote:...But, i was wondering about the logistics or using brick to form a dome-like roof (somewhat common in Mexico). However, another aspect is that it would be in a fairly rainy and cloudy place, with lots of wind... Could it be possible? I know i'd probably have to hire out because brick roofs are hard to master (probably wont stop me from trying and failing anyways lol), but was just wondering if it would even be physically possible before i start making the plans.

If that's not possible, would an alternative be to just use cob itself? if you created a good enough lime seal (maybe even tadelakt) and made sure that it had spectacular rain run off, would it hold up or would it simply wind up disintegrating?

Hello Hamza ! Where are you located? Phil had some good links, I'd like to add some pics and a few thoughts. Now, don't let my words discourage you, I wanted to do this also, but the expense and headache disappointed me. I didn't have the resources. Perhaps you would, however.

You are looking at a masonry vault of some sort. And modern governments do not like to approve the building of structural masonry vaulting. The skills died off, and very few people kept doing it, but people today are re-discovering it from a technical, engineering, and practical standpoint. The idea - if in a seismic stable area - is ecologically brilliant in that you aren't cutting down trees. Wood's renewable but cutting down entire forests to build roofs and floors has obvious impacts. However brick, cement, burned lime, all have encological tradeoffs too. But the results have a permanence that can last generations.

You would need to have it engineered to get anything like this approved, and

very few modern engineers would ever want to touch brick vaulting. If someone could and did engineer it then they would probably want you to use a lot of rebar. Also builders today really don't know how to do structural brick vaulting. Now, if you know Mexican builders who know how to do this, then at least you'd be able to hire someone. But if this is done in the USA the labor costs as well as the costs.

If you can find a structural engineer who actually understands vaulting, and is willing to design a vault, and understands the geometry and material and their behavior and trusts it enough not to put 50 tons of steel over your head and a concrete slab just to make it work, then you may be able to get it done. OF course in most places the engineer has to be licensed with the state in order to stamp plans. Maybe you can explain it well enough to an engineer who doesn't specialize in vaults, enough that hes'willing to take a stab at it.. Now,

if you have time and financial resources, and

if you live in an area where building inspectors would be willing to sign off if its properly engineered, and you have access to an engineer willing to do this, then you could pull it off.

To do so you would want to really, deeply, understand what you would want from an architectural and engineering standpoint, enough to explain it, and direct him or her to other technical resources. Me, I don't have the time, money, or patience. Maybe someday.. ther'es a reason why stick built ceilings are the norm in America though. It's well understood and everyone can build one and the skills needed for builders are much less..

Basically what you want to do is a vault. I've pasted some pictures below to look at. it's physically possible, and sustainable. For tile vaults, Phil's links are great places to start. From there just do more searches on "timbrel vaults" "Guastavino vaults" "tile vaults". In Italy I think they are called Realine vaults (if I recall, something to that effect). Also look up "Catalan Vaulting."

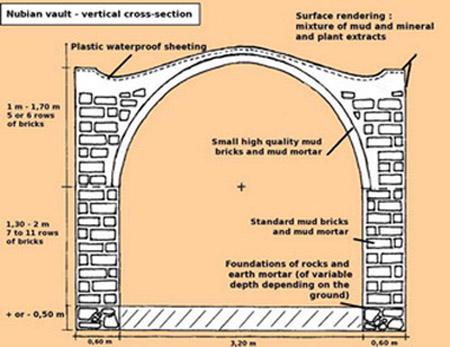

Waterproofing is an issue. You mention tadelakt - that's a labor intensive technique, especially over a whole roof. And you would have to maintain it on a regular basis. Vaults are masonry. Water + Brick + Mortar joints + Freeze/thaw cycles are bad... cracks let water in, and compromises the building. Traditional techniques like tadelakt should be read up on. In modern times when vaults are done (look up French documentation on Nubian vaults in Africa, there's a whole useful How To manual floating around in pdf showing exactly how to design and build a barrel vault ceiling with adobe bricks. The same techniques would apply to any kind of brick) you would want a water proof barrier over the vaulting. Like plastic sheeting, maybe a couple of layers, well taped. There's some pdfs out there on how to do this.. Some architects have used tile vaults as a stay in place form, then poured a concrete slab over it. This has to be done in a balanced way so that excessive weight from the pour doesn't cause collapse of one area.

The brilliant thing is that some kinds of vaults grow more stable when under a balanced load. But the load has to be balanced, and point loads in one area avoided..

The main problem is dealing with the thrust, the geometry of the brick vaulted roof is important. The more curved it is the less thrust, or rather the lines of thrust follow the curve of the vault to the ground within the thickness of the wall the ceiling or roof rests on. The flatter the arch, however, the more the thrust spreads out. You need something to buttress the walls. If this is miscalculated or poorly build you end up with tons of bricks falling on your head.

Tile vaults are lighter, so they produce less thrust. That's what allows them to be more easily built freehand, without a form to support the bricks or tiles. But still the walls have to be able to absorb the load generated by the thrust, and carry it safely to the ground and foundation. One trick modern builders do is they pour a reinforced concrete ring beam and they "spring" the vault from a point contained in the beam, that way the beam absorbs much of the thrust, doesn't rupture from the load, and safely transfers it down the load bearing walls down to the foundation.

Back to waterproofing, you mentioned tadelakt and lime: Something you might want to read up is what's traditionally done in the North African Maghreb. In some parts of Morocco lime sealed roofs are still done, mainly in renovation and maintenance of older houses. I don't think it's done at all in Algeria or Tunisia anymore though. I have read about this still being done in Morocco, though. Mainly not in new builds, but rather in repairing older housing stock. Modern builds are mostly done in concrete. Traditionally the roofs are earth slabs, compressed with rollers. Basically Cob over wooden rafters/joists, with a formwork (shuttering) later of branches or leaves. Incidentally exactly how adobe roofs with Vigas are done in the old American south west, and Mexico. (And also the case in other parts of the Arab world, in the middle east).

I have heard this is still done in some rural Berber houses, by the way. So that may be a place to research.. Now, over this compressed earth slab floor/roof you put a lime layer on top. Its basically what people would call limecrete today. A few inches of lime mortar, compressed and worked in and burnished. This consolidates the material, works out air pores, makes it denser. Then some sort of fat, or soap, applied while the lime is hardening but still somewhat plastic, and then worked in. It's similar to tadelakt. Once fully dry and cured it's basically a lime based concrete with a water resistant surface layer bonded to the material. Fats or soaps react to the lime itself making a crust, exactly the stuff that you get on your shower walls over time. Here it's structurally part of the lime surface, and thick. However it needs maintenance. In Yemen there's a similar technique called Qadhat. Both are extremely resilient, crack resistant and more flexible than concrete, but you aren't gonna find anyone nowadays who knows how it's done.

It's extremely labor intensive. That's why no one in that part of the world likes to do it anymore, and the skills needed mostly died off two generations ago. In Morocco the government subsidizes certain building crafts like this, and in Yemen the Agha Khan foundation subsidized them, so a new generation of masons and builders are learning them from the old masters. Also there's demand in Morocco for traditional housing from Western expats. Hopefully that will keep these natural building skills alive...

In today's world you would probably just want to do two thick poly sheets, properly sealed and taped, and do a basic one or two inch limecrete layer over that, or even concrete. Or latex concrete. Or something akin... So enough about water-proofing, what about the roof itself? Well, again, you are doing a brick or a tile vault, as Paul indicated. The two are similar, but there are differences.

Back to tile vaults:

This example, from an old house in Barcelona I think, illustrates the layered composite nature of the vault, the layers overlap, embedded in the mortar, as it cures it becomes almost a monolithic concrete like mass.

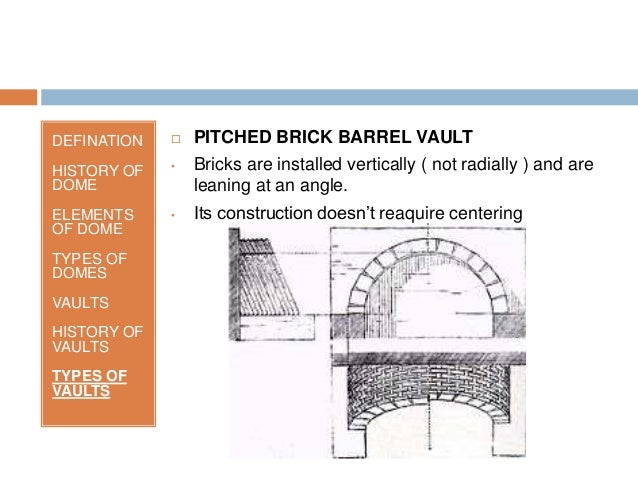

Now, you mentioned Mexican style vaults. They are different from timbrel vaults, but the techniques are related in some ways and tile vaults probably evolved out of earlier freehand brick vaulting techniques. Both are usually done freehand without forms, but Mexican vaults "Bovedas" are single brick thickness.

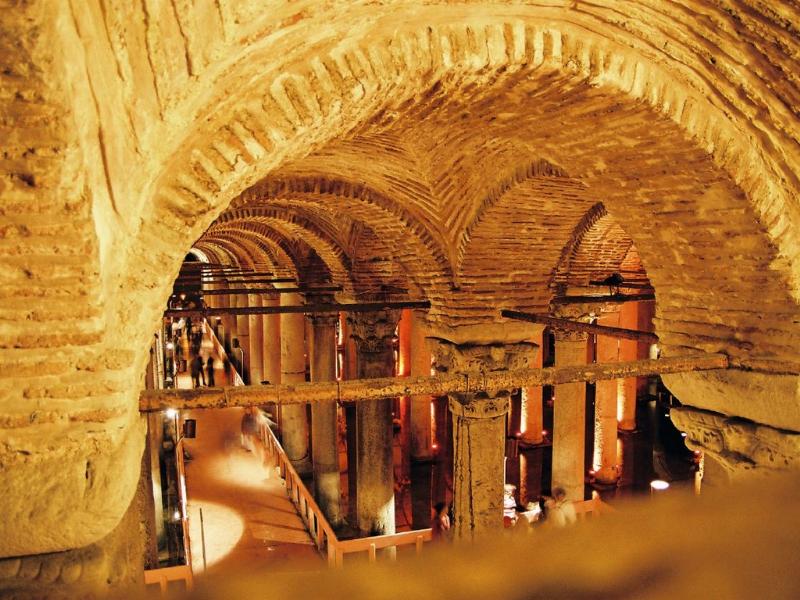

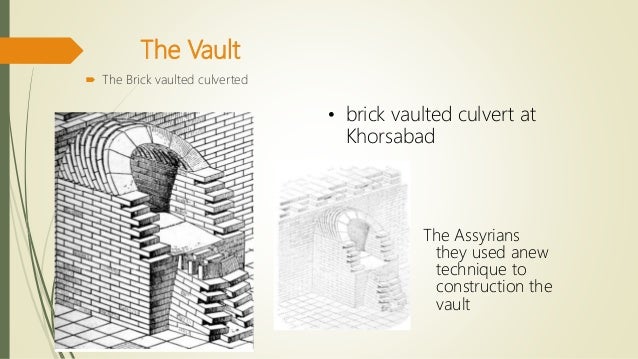

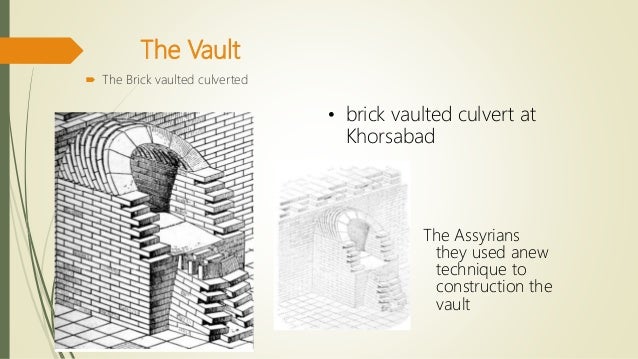

The technique is very similar to what was done in some parts of the Middle East and North Africa. Look at pictures of the "Basilica Cistern" in Istanbul. They were done using a very similar technique as the Mexican ones.

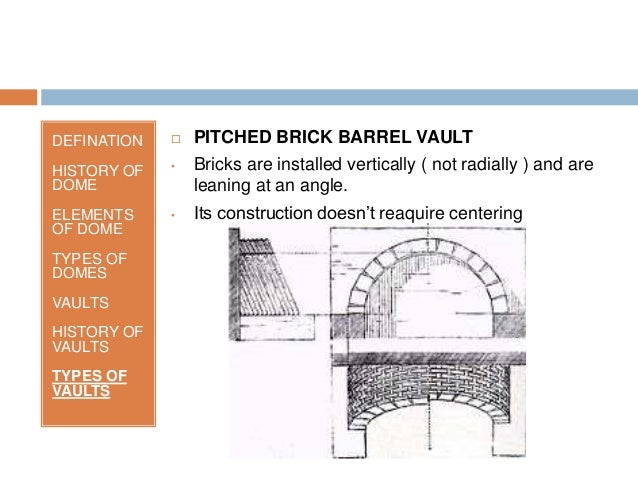

It is a "leaning brick" type of vault, the bricks are porous, the mortar is sticky. If you Google "leaning brick vaulting" or "pitched brick vaulting" you will find lots of information. The technique was common in Sassanian Persia, ancient Egypt, the Romans adopted it but didn't use it much in the Western Empire. The Eastern Romans however used it a lot and it's found all throughout Byzantine era Anatolia. The Ottoman Turks learned it from them and continued the technique through the province of Rum.

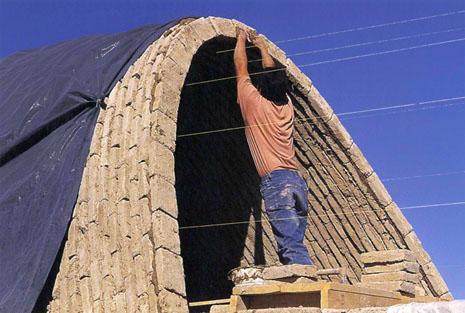

A modern examples of the technique:

This is the Cistren in Istanbul I mentioned:

Other Eastern Roman/Byzantine examples

https://static.cambridge.org/resource/id/urn:cambridge.org:id:binary-alt:20180929073907-12263-smallThumb-05935fig4_64.jpg?pub-status=live

An illustration of the technique:

Now, this is still done today, and there's a bit of a revival, in West Africa's Sahel region. Some NGOs have tried to spread the technique of using Adobe or compressed earth brick pitched barrel vaults in Africa, they are calling the technique "Nubian Vaulting."

Cross section:

Back to the Americas, pitched/leaning brick vaulting done Mexican "Boveda" style :

https://i.ytimg.com/vi/PB8TWMKHHMQ/maxresdefault.jpg

If you look close you can see a poured concrete ring beam on top of the wall, from which the vault "springs":

The Auroville project in India has a lot of information and experience in this. You may want to look for their website.

This is one of their vaults:

http://1.bp.blogspot.com/-fXSMpWD_7c0/Tw2K1OiLGaI/AAAAAAAABEU/xa4iZ_vfn70/s1600/8.jpg

About the tile vaults Phil mentioned, there's a professor at MIT who has done a lot of research into them, and did work on getting them accepted once more in the Engineering community. There's lots more interest and projects being done, but the odds of finding someone who knows how to do or design them is low.

An example in New York:

Cob.. wouldn't work, as Phil says. But adobe vaults can and have been done. The odds of getting an engineer or building inspector to approve them is even less though.

Example pics:

One being built in Mexico out of adobe:

http://caneloproject.com/pages/mexico/dome.html

There's a builder in Tanzania who blogs about this, he and his building crew have done many of these kinds of vaults and has a LOT of practical knowledge. An engineer designs them, then he builds them. If you can find his blog it's an amazing gold mine of information.

Anyway I hope that gives you some places to research, some inspiration, and that you have the resources to get this engineered and pulled off.

Natural or alternative building enthusiasts, and Permaculture enthusiasts, all need more aggressive lobbyists and public outreach.

Natural or alternative building enthusiasts, and Permaculture enthusiasts, all need more aggressive lobbyists and public outreach.