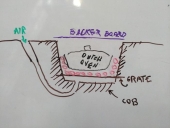

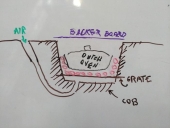

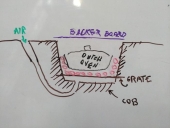

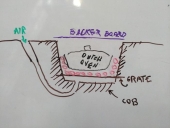

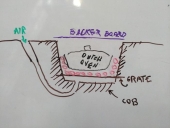

I'm planning on a rocket stove for 24x32 barn with decent insulation. I'm wanting to make the mass out of (2) steel 55 gal drums welded end to end, fed by a batch box made of fire brick and a CFB riser. The bell is a 55 gal steel drum over the riser. The CSA will be about 25sq in. (5"x5"). The (2) 55 gallon drums as the mass. So I have a few questions:

1) what's the difference between a j-tube and a batch box?

2) If it's a batch box, I understand that I need a 2ndary air inlet.

3) Can I get by with single wall flue pipe, or do I need double wall? Flue pipe is pretty pricey.

4) What kind of insulation do I need underneath the mass? Can I use rigid foam board?

5) What about having the burn chamber below ground level? I have a dirt floor in the barn.

6) Is the mass ever too big? Like I said, I'm going to have (2) 55 gal drums end to end covered with cob and rocks.