Hi, new here.

Ive been researching PVB batch boxes for a while and have a few questions about a design I wish to implement

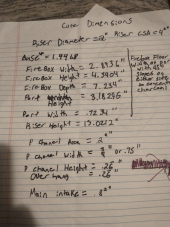

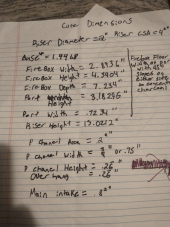

Using the ratios on batchrocket.eu I have calculated the size that a box with a 2" riser would be. I havent heard of a box that small being attempted before, and Im curious if the drastic change in size will adversely affect efficiency.

second, I also wish to implement a few design tweaks to the original batch box and once again would like to ask if about potential losses or gains.

the first and foremost tweak would be moving the port to the top of the firebox, rather than the rear, similar to the double shoebox design seen on peter van den berg's more recent videos. However, unlike the more square shape seen in his videos, I would like to retain the long(tall) narrow port that the original batch box design has.

I have questions about the double shoebox design in general, how efficient is it compared to a regular batch box. How do the measurements in a horizontal riser compare to that of a vertical one, considering that in the original design the riser is taller than the firebox is long. could the horizontal riser simply be shorter and retain the same CSA as a vertical one, or would the CSA have to increase to account for the shorter length?

can a vertical riser be used with a port that rests on the top of the firebox?

another design change I wish to implement would be moving the 45° angles from the bottom corners to the top corners of the box. I am unsure about whether those would extend all the way back in the firebox or stop just shy of where the port would begin.

Finally, If the port is on the top, could the p channel simply be straight into the port rather than L shaped down into the firebox

If any or all of my questions could be answered, that would be great. I have included a few rudimentary drawings I have to illustrate certain design tweaks