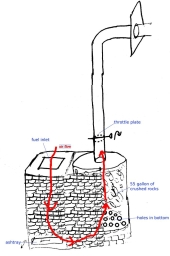

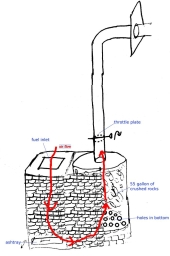

Phil Stevens wrote:Have you built a J-tube according to the dimensions known to work? There are several factors at play, so it's a good idea to start with a tried and true configuration and then experiment to see how far you can depart from the basic design, changing one parameter at a time to figure out if it will work or not.

Just by looking at the plan, I think the feed tube is too tall and will be prone to creating a reverse stack effect and working against the desired flow. I'm not sure I understand the air holes in the barrel holding the rocks...is this a secondary combustion chamber? Sending the combustion gases directly through a bunch of rocks will remove too much heat from that zone, hampering the burn and stalling the draft.

Michael Cox wrote:Industrially, solids are burned using a fluidised bed. Dry the slurry, crush it to power or lumps. Tip it into a vertical tube, and blow air into the bottom. You are aiming for just enough velocity to suspend the particles to be burned without blowing them out of the top. You obviously need a source of ignition as well.

This system if done properly is clean burning and robust, but needs to be designed well and would be sized for large scale use. Think, toilet waste from a medium sized community. Not and individual toilet. You run into all sort of problems of scale trying to burn tiny masses of material - heat loss to the fabric of your incinerator etc... You would need to supply large amounts of external energy (heat) and have a super insulated system to ensure a clean and safe burn. Way beyond the technical capabilities of a typical cheap DIY system.

We have used composting system here with great success. Incredibly low tech - literally a few plastic buckets and some sawdust free from the local sawmill. Look up the "Humanure Handbook" - available as a free pdf.

Gerry Parent wrote:Hi Douglas,

Before delving into the complexities of your plan, have you ever tried a much simpler bucket compost method?

An internet search for "humanure” willbring up lots of good information.

John C Daley wrote:Yes its possible, using a pond with a glass roofing apon which the evaporating water can condense and trickle away to a container.

A similar process can be used to catch dew at night.

This web page explains the mechanics of the process

Solar water still

And another which I found by searching for 'grey water distillation'

grey water distillation