Hey everyone! im super excited to do some metal working with yall this summer and it seems there is a lot of interest in a rocket forge experiment so lets get it started!

tickets to the PTJ can be found here! -->

https://wheaton-labs.com/permaculture-tech/?f=625

The goal of this project is to build a forge and bellows, and to experiment with a rocket forge. students will learn the basics of forge design, hammer work, and heat treatment of tools. experiments will be conducted to incorporate rocket design features (clean burn, self feeding, natural draft) into a functional forge. the Lab will be left with a functional forge that will burn wood, charcoal, or coal and a bellows to provide the air.

phase 1. Building the forge and bellows:

we will build a "regular" forge. using simple materials from the site we will construct a forge that anyone can replicate at home. an ancient design that still sees use by talented metal workers to this day. Uncle Mud wants to call it a Dirt Forge. people on the smithing forum "iforgeiron" sometimes call it a JABOD (just a box of dirt) (pics to come)

a set of hand operated bellows will be built to provide air for the forge. (pics to come) the forge can be run with a thrifted hairdryer as the air supply if people are feeling anxious to get a fire going before the bellows are done.

the dirt forge and bellows will work as our control so we have something to compare our rocket experiments to.

phase 2. rocket experiments:

broadly speaking there are two approaches here.

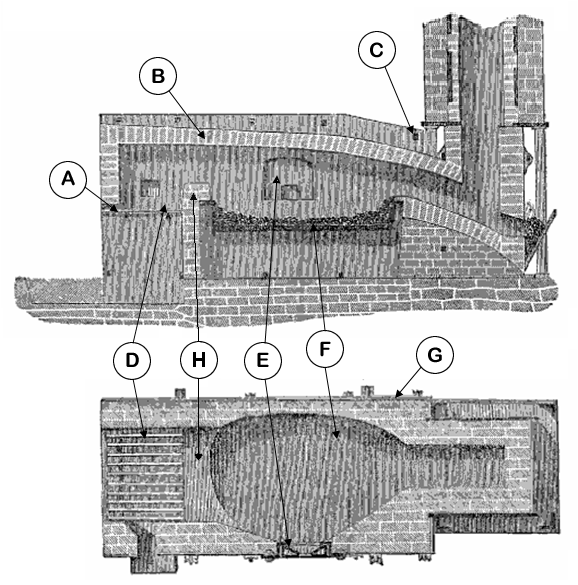

1. direct the hot exhaust gases from a rocket engine into a insulated work chamber where the iron is heated. this is most similar to how modern propane forges function and is how the current rocket forge functions.

2. use the strong draft of the rocket riser to pull air thru the fuel (wood, charcoal) and bury the iron to be worked directly in the coals. this is most similar to how solid fuel forges work and takes advantage of the greater heat transfer between the coals and the metal, rather than just using the hot gasses.

we will have a beautiful 8in rocket engine to play with for these experiments, as well as the basic materials to cobble together a simpler rocket core

note: throughout phases 1 and 2 we will be using both forges to construct blacksmith tools that will stay at the lab

phase 3. goofing around:

building a small retort for making charcoal that can be placed on top of the rocket riser. wood gas can be sent back into the system.

make the bellows pedal powered!

find other projects around the site that could use some fancy iron work

did a bit of poking around the forums and gathered up some good information about the work thats already been done:

the rocket kiln project last year produced some great data here:

https://permies.com/wiki/184037/Inch-Portable-Modular-Rocket-Engine

my notes from this thread:

8 in engine kiln in low position 2077 bottom 1945 top. 2 hours (pass thru)

6 in engine kiln on top of riser 2296 bottom 2259 top. 5 hours (pass thru)

Pauls 2088 top 1945 bottom 5 hours (captive design)

these numbers represent the "heat work" done inside the kiln. for hobby smithing work these temps are fine, the question is can we get the steel to these temps in a couple minutes rather than a couple hours.

this thread has a lot of good ideas too. dealing with forge design (for smithing) and furnace design (for melting metals):

https://permies.com/t/166851/rocket-forge-steel-insertion-crucible

my notes from this thread:

A hole or door in the vertical riser in the sweet spot. (this is the current version of the rocket forge)

The hole could have a foot activated door. (not an uncommon design on modern propane forges)

Built in retort after the forge area for making charcoal, wood gas to be sent back down to the feed tube. (there seems to be interest from others here. might as well utilize some of that wasted heat)

Multiple feed tubes with risers spiraling around a central crucible. (love the go big or go home energy)

Paul says no shop vac for the rocket forge/ furnace experiment. (i agree. if we are gunna use a forced air draft its not really a "rocket" any more)

Paul thinks crucible access should be from side. (meh. top access for loading materials during firing is nice)

Insulated chimney above work area to increase draw. hopefully will help the forge draw better even if the forge doors are opened