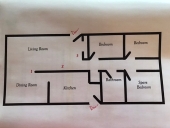

Good for you for trying stuff! I hope you can clarify your setup for us; I can't tell from the photos how the airflow is supposed to work, You say you don't have a "fire tunnel" (burn tunnel is the standard term)... I take it the

wood feed is the about 4" diameter hole? What is the internal shape and size from there? It looks kind of like a square hollow much larger than the feed hole. That would not work at all for making a rocket combustion chamber. You need a vertical feed tube leading to a shortish horizontal burn tunnel, leading to a longer vertical heat riser. All of these need to be approximately the same cross section. The feed tube and burn tunnel are generally built square, while the heat riser can be square or round (round is more efficient by a bit).

I am assuming that you plan to close off the tops of the chambers with slabs that we don't see.

What kind of clay did you use? If it was ceramic or pottery clay, I am concerned that it may not stand the fast temperature rises you get in a rocket combustion chamber. Even if it is bone dry, there is still

water bound up in clay, and if heated too fast it will flash to steam and explode, destroying the clay.

You need insulation around the combustion chamber, like perlite, so it doesn't lose heat too fast and burn cool and smoky. This is especially important for a 4" system size, which is at the small end of what is possible to function, and is often difficult to get right. Larger sizes are more forgiving and easier to get right the first time.

1

1

![Filename: Vulcan.jpg

Description: [Thumbnail for Vulcan.jpg]](/t/61323/a/46152/Vulcan.jpg)

1

1