I had to take some trees down in preparation for new leach field (erosion removed 80% of the old one build 70 years ago).

Unfortunately, with the new town requirements, I have to install a new 1000 gallon concrete tank, plus an effluent pumping system.

The new leach field will be 100 feet away from the main tank and about 35 feet higher.

Still haven't had what I'd consider a reasonable estimate for the job.

And while I try to do most jobs myself, moving 10,000 pounds of concrete tank down the hill and around a corner - well, I think that one is just a little out of my league!

But the real point of

this thread is - I cut, split and stacked the birch trees and then looked at the wood shed.

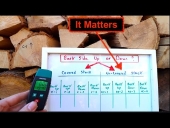

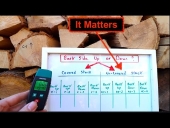

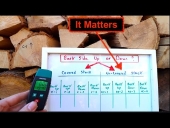

Inadvertently, I had stacked almost all the logs with the bark side up.

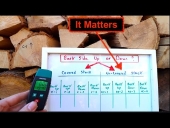

Since the shed is not entirely weathertight, should I have changed the log orientation or gone all bark side down, does it matter?

When you stack your firewood, do you pay any attention to the orientation of the bark ?

Thanks!

No, I'm not going to restack anything, but I always have more trees that fall over, so this surely won't be my last fell, cut, split and stack day