10

10

9

9

7

7

4

4

9

9

5

5

5

5

John Daley Bendigo, Australia The Enemy of progress is the hope of a perfect plan

Benefits of rainfall collection https://permies.com/t/88043/benefits-rainfall-collection

GOOD DEBT/ BAD DEBT https://permies.com/t/179218/mortgages-good-debt-bad-debt

14

14

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

7

7

Adhesive cement

You would probably have a better chance of success by chiseling away some of the mortar in the places the stones fell out to make some room for a good coating of mortar (1/3" at least).

Adhesive cement might come in a bucket ready to use, in a bag to just add water or as an additive (powder or liquid) that you add when making your cement mortar.

7

7

John C Daley wrote:Am image of the4 damaged wall would help a lot, otherwise we are dealing with words alone.

9

9

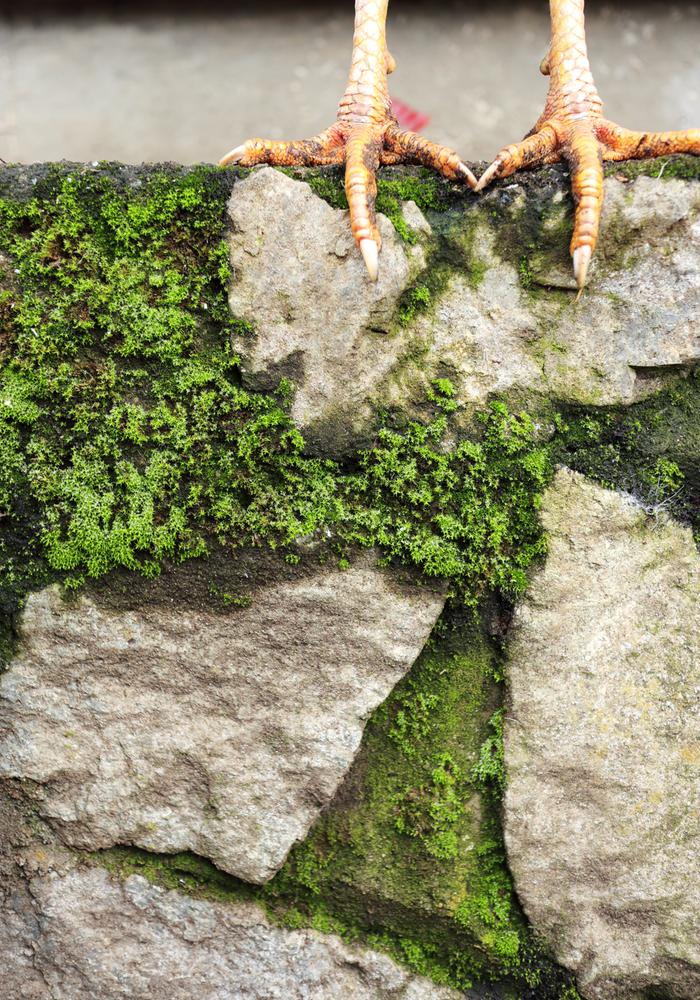

r ranson wrote:Chicken foot is for scale.

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

3

3

9

9

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

8

8

8

8

10

10

EBo --

Master Gardener (Prince George's County, MD, USA)

8

8

- Tim's Homestead Journal - Purchase a copy of Building a Better World in Your Backyard - Purchase 6 Decks of Permaculture Cards -

- Purchase 12x Decks of Permaculture Cards - Purchase a copy of the SKIP Book - Purchase 12x copies of Building a Better World in your Backyard

8

8

EBo --

Master Gardener (Prince George's County, MD, USA)

7

7

There are several types of mortar, including Type M, S, N, and O, each with different strengths and applications.

5

5

|

So it goes - Vonnegut

permaculture bootcamp - gardening gardeners; grow the food you eat and build your own home

https://permies.com/wiki/bootcamp

|