Peter van den Berg wrote:

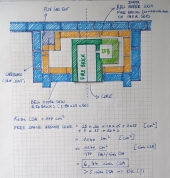

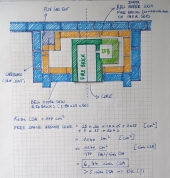

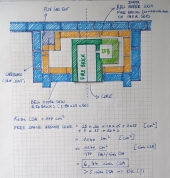

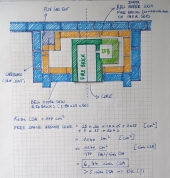

The bell could be deep and tall, no problem. Down to just wide enough to house the core, although in that case there should be at least a space at the back. Size of that space: at the bare minimum, 5 times the cross section area of the stove pipe, more being better. That space is there to lead the gases down to the bell exhaust.

Leonardo Bevilacqua wrote: Hello everyone, this is Leonardo from North Italy.

Leonardo Bevilacqua wrote:

For the bell I thought about a stratification chamber made of concrete clinkers lined with firebricks in the upper part. I also thought of a double layered bell so that it would retain the heat longer.

Leonardo Bevilacqua wrote:

Does this project sound good to you all? Is there anything that I'm not considering, or considering wrong? Do you think I could go on calculating and drawing a detailed design? Would such a heater heat the two rooms? Would it somehow heat a bit also the second floor?

Cristobal Cristo wrote:

I'm just curious, how many bricks have you managed to bring total?

Peter van den Berg wrote:

The ISA for the Shorty core is down to 85% of the recommendation for a first generation core.

Peter van den Berg wrote:

Tried last month with the large heater in the Sculpter's shop

and it works beautifully