Need more info?

Ernie and Erica

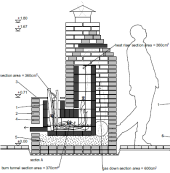

Wood burning stoves, Rocket Mass Heaters, DIY,

Stove plans, Boat plans, General permiculture information, Arts and crafts, Fire science, Find it at www.ernieanderica.info

Need more info?

Ernie and Erica

Wood burning stoves, Rocket Mass Heaters, DIY,

Stove plans, Boat plans, General permiculture information, Arts and crafts, Fire science, Find it at www.ernieanderica.info

Need more info?

Ernie and Erica

Wood burning stoves, Rocket Mass Heaters, DIY,

Stove plans, Boat plans, General permiculture information, Arts and crafts, Fire science, Find it at www.ernieanderica.info

preferably a whiskey and a pipe

preferably a whiskey and a pipe

but you see the point - too much heat too quickly isn't desirable in a greenhouse situation and, even with added insulation, is going to be wasted quickly too, through the glass.

but you see the point - too much heat too quickly isn't desirable in a greenhouse situation and, even with added insulation, is going to be wasted quickly too, through the glass.

better taste and warming.. I am trying to do diagnostics on a stove via pictures the darn lawyers keep getting in the way of the screen if you get to many you wont know what your writing. Any how it sound good But i dont want to add more work for you I am of the warm butt group myself so i am trying to get the figures on how i fix every problem Including the butt shelf.

better taste and warming.. I am trying to do diagnostics on a stove via pictures the darn lawyers keep getting in the way of the screen if you get to many you wont know what your writing. Any how it sound good But i dont want to add more work for you I am of the warm butt group myself so i am trying to get the figures on how i fix every problem Including the butt shelf.

Need more info?

Ernie and Erica

Wood burning stoves, Rocket Mass Heaters, DIY,

Stove plans, Boat plans, General permiculture information, Arts and crafts, Fire science, Find it at www.ernieanderica.info

Need more info?

Ernie and Erica

Wood burning stoves, Rocket Mass Heaters, DIY,

Stove plans, Boat plans, General permiculture information, Arts and crafts, Fire science, Find it at www.ernieanderica.info

-I guess this could be useful if I ever get round to rebuilding the greenhouse.

-I guess this could be useful if I ever get round to rebuilding the greenhouse.

There's always a compromise position tricky bit is finding it.

There's always a compromise position tricky bit is finding it.

maybe because of contact area - close contact with cob, point contact with brick - I'll try cobbing the bricks into place tomorrow.

maybe because of contact area - close contact with cob, point contact with brick - I'll try cobbing the bricks into place tomorrow.

I fear I have trouble looking the stuff in the eye now

I fear I have trouble looking the stuff in the eye now  Whiskey however goes down like mothers milk and calms the Seafaring Scottish blood that finds itself stuck in this Sassanach landlubber

Whiskey however goes down like mothers milk and calms the Seafaring Scottish blood that finds itself stuck in this Sassanach landlubber

| I agree. Here's the link: http://stoves2.com |