posted 6 years ago

That should work to heat the home, but I did not see many controls for overtemp situations. That is my biggest concern.

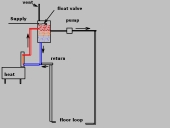

If your thermos siphon does not work as planned (they often do not) you could just add another circulator pump and force a hot water loop. But try it and see first...

There are a few details I would be interested in, like individual pex loop lengths in your floor, but if all of them are exactly the same length, then you should be fine. If they are different lengths, then you might need flow control valves (quarter turn ball valves will also work as flow controls by varying the degree of closing), otherwise you will get uneven heating in individual pex flooring loops. If your pex loop lengths vary in your floor, then you would need a flow control in each pex loop, of some sort, to balance out the system. It sucks, because once set, it is set for life, but with varied loop lengths (like my house) it is required to balance the floor.

You also might need a flow control valve on your pex return manifolds to ensure your flow is proper through the pex tubing, this ensures you get your delta T, or 15 drop in temperature to ensure you are getting proper heating of your floor. It is simple, if your water temperature entering your floor in 90 degrees, you have to control the flow coming out of the return manifold so that it is 75 degrees. If it comes back as 80 degrees, you are not slowing down the flow enough to let that hot water properly heat your floor, and if it comes back as 70 degrees, then your flow is too slow. It has to be 15 degrees...also called Delta T, and is critical.

My real question is, what are your controls for over-temp water?

If you have concrete floors, it is critical that you do not get above 110 degrees or it will degrade your concrete. There is only two ways to knock down the heat, but the cheapest (and less effecient way) is to inject cold water from domestic hot water as a regulating device. I am not sure how you would control this temp though inexpensively without a PLC.

If you have wood floors, the concern of over-temp is not that bad, but I did not see anything listed for thermostats, relays, or zone valves. Without these, you will not get very consistent heat, but you need that for concrete floors too, and you did say "slab" leading me to conclude you have concrete.

I make the assumption that on your expansion tank you have your vent, relief valve, air eliminating valve and make up water? It typically comes as a kit with your expansion tank? You will need all that because while your woodstove/55 gallon drum loop is not presurized, your radiant floor heating system is. If your woodstove ever was to boil the water, that means the water in your radiant floor system would be over 212 grees and flash to steam, you would need a relief valve to insure it did not go bang. Always remember with radiant floor heat, there are two systems: the primary loop and stove, and then the radiant floor heating system. They are two systems woking in unison.

1

1