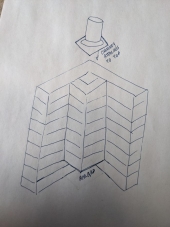

I'm pretty sure the "juice box straw" design is a metal chimney in a bell.

I'm not sure if it has ever left the design stage.

I'm not sure why the part of a metal chimney inside the bell would need to be insulated.

Usually we insulate a chimney to keep it hot and thus maintain draw, but would that be a problem inside of a bell?

The top of a bell gets hella hot and is often made of special materials to deal with the heat.

Maybe we need to protect the metal chimney from the high temperatures at the top of the bell?

Depending on the material, poking a hole for the the metal chimney to exit might be very difficult.

For example, the walker cookstoves often use the glass top from an electric stove as the top for their bell, and you can see above the masonry part of the chimney rises outside of that footprint.

That design preserves cooktop area and it means no need to cut the extremely tough Glass-Ceramic material.

So,even if if you use a metal chimney inside the bell,it might be better to have it rise to the ceiling of the bell,turn 90 °and exit the side.

A tee fitting inverted at the bottom of the chimney,with one arm poking out the side of the bell could offer the perfect place to put a clean out cap.

EDIT: A better name for this design might be a "plunger tube"

Glenn explains it in this thread:

https://permies.com/t/367651/tube-RMH-barrel-stratification-bench#3733843

The insulation is there to"reduce heat leakage from the top of the bell."