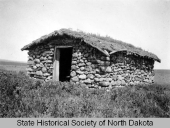

My house is approximately 1880 a natural stone construction built on soil. I am at the first stages of experimenting with clay mortar and need to infill voids between the natural rocks of my house and also the same with the interior , then experiment with plastering outside walls and inside walls .

I believe the exterior walls long ago were plastered but has long since fallen away , only some small areas remain plastered on the exterior walls. It appears to be a very fragile mix , I,m not sure if this was done with pure clay soil or a clay soil with a small amount of cement added the same is true for the areas on the interior walls, it is a fragile crumbly mix and can easily be picked off the wall, the small stones in the mix appear to be factory uniform.

I think when the wonder material Portland cement arrived the locals here may have used it and added it to the clay , i have taken some of the internal wall plaster and ground it up and it has a rather acrid stench to it, i cannot be sure of this though , all i know is that it has far less clay content in it than stones , totally crumbles up.

The mortar between the wall rocks though appears to be genuine wild collected clay ranging from white to red interspersed with natural stone / rock fragments and fragments of slate ranging from 1mm up to 10 to 15mm in totally irregular shapes. This has a definite tough feeling but can be broken up with a good amount of pressure / hammering.

My question is with my limited range of sieve sizes { and knowledge ) what sizes and ratios should i mix the fine clay to stone / particle sizes to fill the voids between the wall stones.

My sieve sizes are : 10mm 6mm 3mm 1.2mm 0.6mm , and from the 0.6 the clay fines pass through.

I have meticulously taken samples of the collected clay soil from my forest , from the wall rocks void mortar and the wall plastering and sieved them all. I have made notes of the amounts of each sieve sample then drew a bar chart of each size and its volume in milliliters then calculated % for each size in the sample, over this i plotted a curve as a guide to compare each sample, so i,m making inroads, i think but i,m not sure what stone grain sizes should be chosen for the void mortar and the wall plastering .

I,m looking for a starting / reference point from someone who has done this please , can anyone point me to a clay experimental / success area .