Josh Hoffman wrote:...

Since it stays very hot here (chill hours are around 450 a year or so) the coop/run is open at the top and on the south side. Since it is on a slight slope, we get some ground water intrusion on the north and east walled side (during torrents) and coming in when the wind blows sideways while raining.

The chickens roost in the rafters and some other lower spots. This allows us to use the same deep litter of wood chips/grass clippings/leaves, etc. for the entire coop/run. We could not do this if we experienced colder temps.

Matt McSpadden wrote:...One issue was that it was on a slight slope....

Josh Hoffman wrote:...But, adding the 2x6's and using the deeper part that collects there has been very manageable and I think most anyone could make it work. If you have a steep area, I could foresee some issues with the material moving along too rapidly. Adding things to slow it down, in closer intervals may be the solution...

Joseph Lofthouse wrote:That type of mega-huge cataclysm seems too big to survive, therefore I don't prepare for it, and don't know of anyone that does. Same way that I don't prepare for a mega-astroid strike, or the sun going super-nova.

Tons of intentional communities prepare for normal disturbances like winter snow, civil-unrest, flood, hurricane, earthquake, drought, etc...

Steven Lindsay wrote:although the US 'stick-build' framing technique is frowned upon by some, it developed precisely because there was a shortage of 'time and money', and highly trained tradesfolk and resources, but a huge need for new housing.

It's probably your cheapest, most flexible option; you can easily add elements such as insulation, windows, power etc as needed over time, it can be constructed without heavy machinery or even power tools if required, and be completed at your own pace (the only really time-sensitive elements being concrete or other settings materials). You can also design it to fit in whatever available space there is without adding much to the cost or complexity per sq.

It's so well established there are heaps of instructional resources and everything needed is probably readily available, maybe even free, used or reclaimed.

Juju Guerra wrote:Hi!

You are totally right…there actually is ventilation right now via gable vents, but it’s not enough. He is actually planning to change out the windows to provide more. I have not heard that rule of thumb but thanks for sharing that. He is also planning to make a few other improvements as well. I’ll post updates here once we have new photos!!

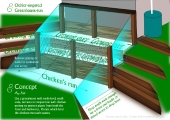

Juju Guerra wrote:My husband recently built a combination greenhouse chicken coop in our backyard/orchard area and we are planning to sell them. The greenhouse is attached to the side of the chicken run and is 4x9 - check out our site for more details: www.sierragardencoops.com. I'll share a photo here as well!