Hi all,

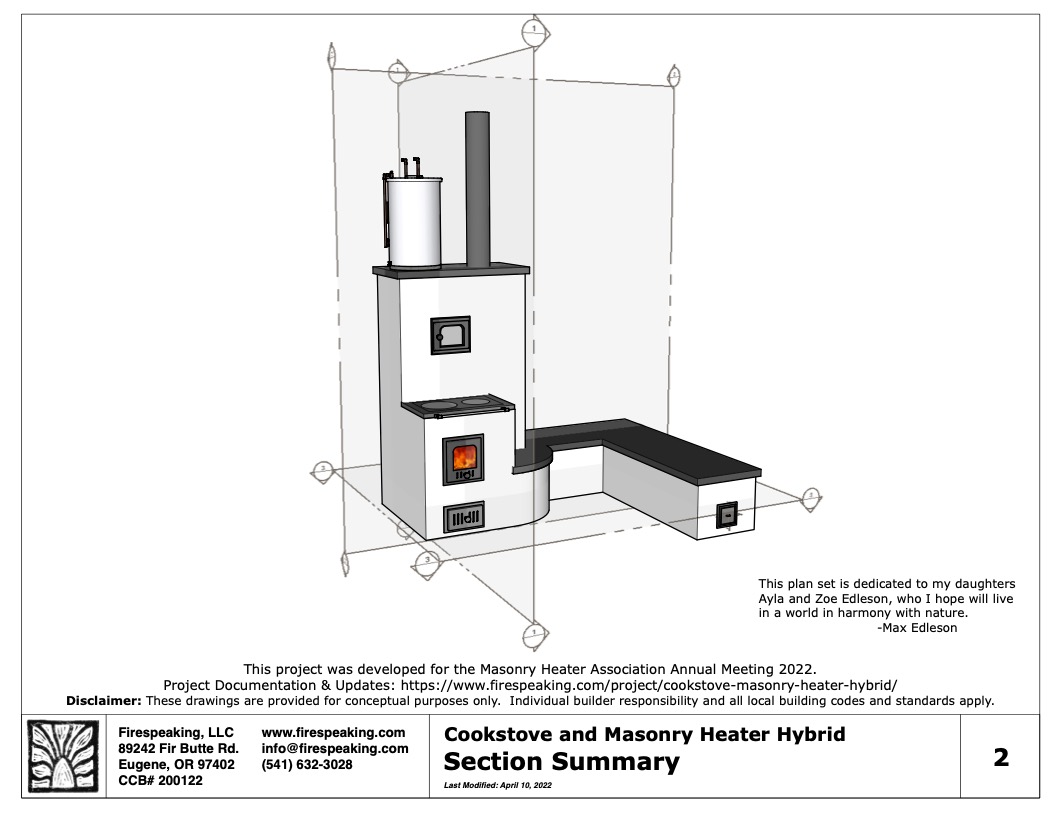

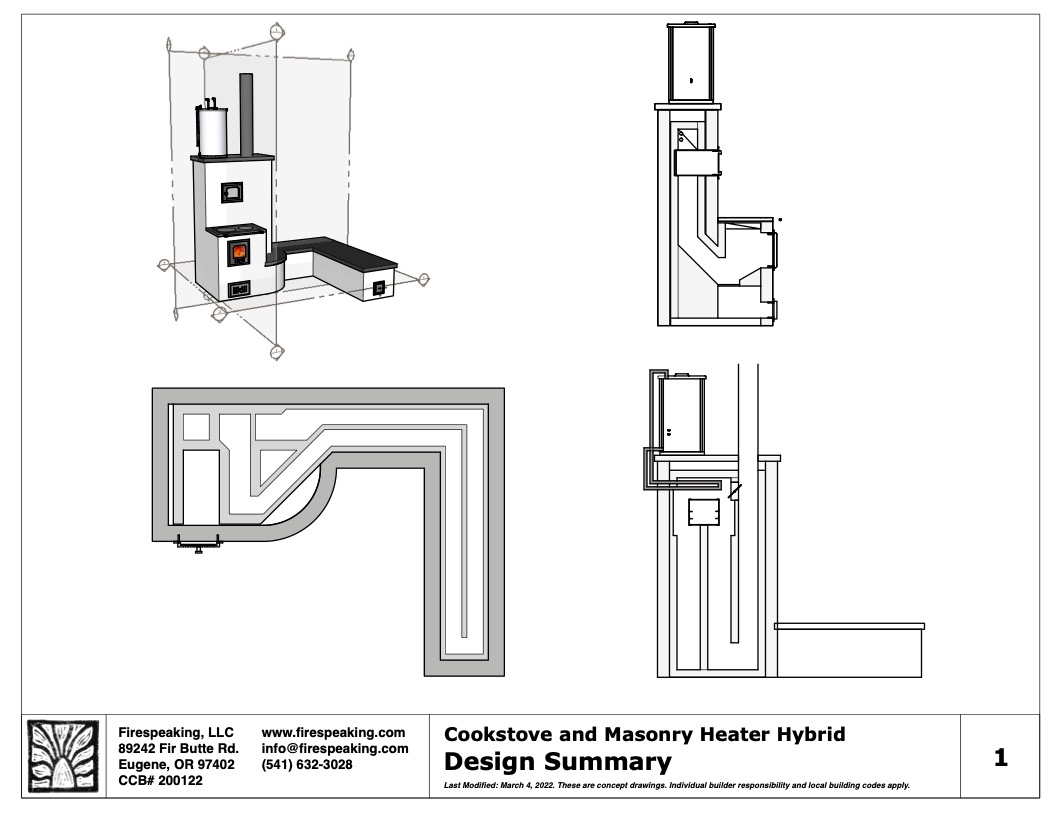

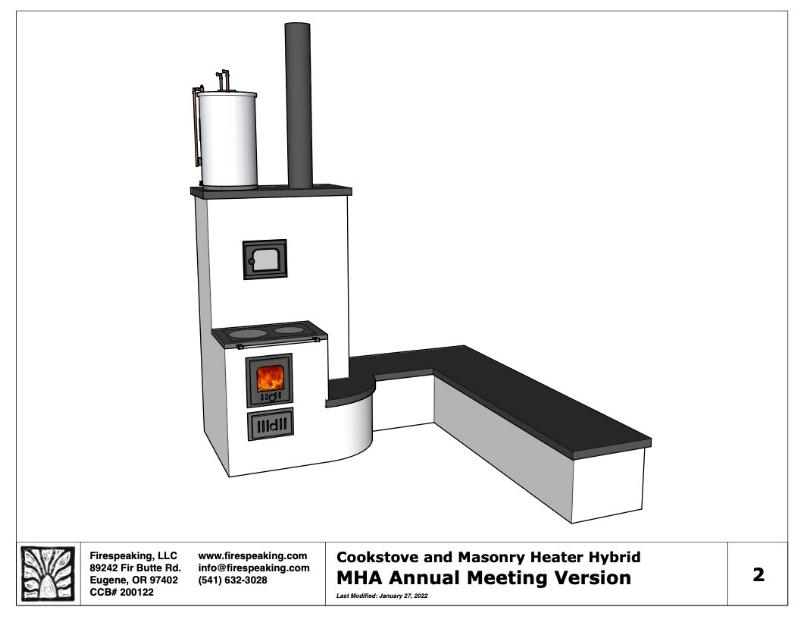

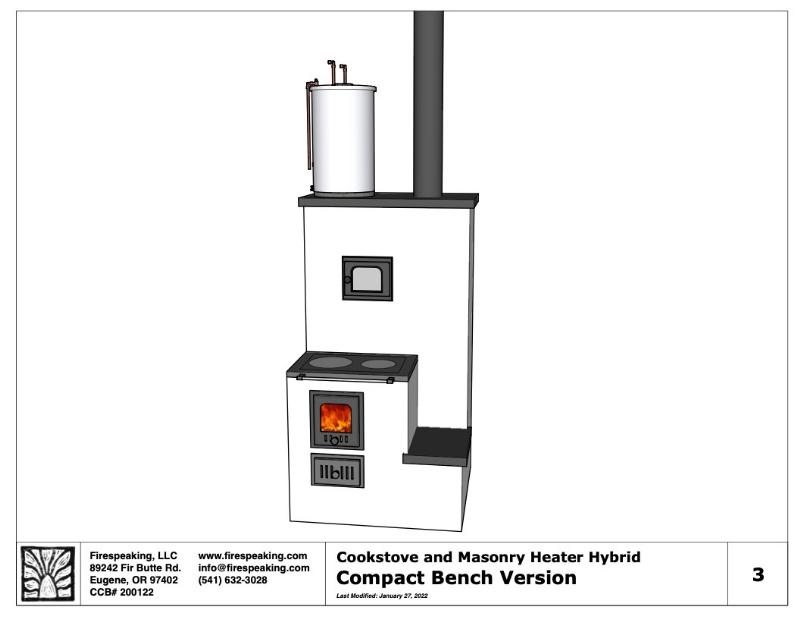

This is a great thread. Indeed, as mentioned earlier in the thread, we at

Firespeaking have offered plans in the past but what we've found is that there is so much background knowledge required to execute the plans that a lot of documentation is needed to support them. This is something we are working on. In the meantime, I can't more highly recommend joining us at the

Masonry Heater Association Annual Meeting in North Carolina

this April where there will be an outstanding list of hands-on workshops.

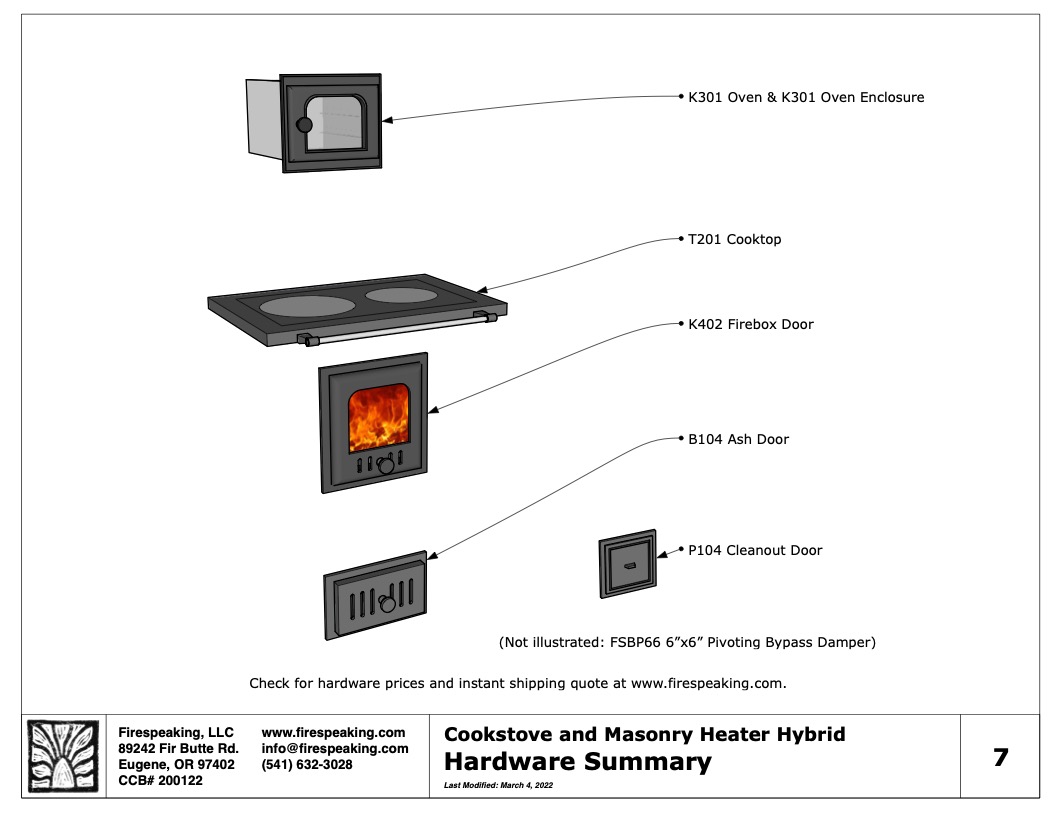

For those of you who have settled on a design, we carry

a whole line of cast iron hardware including firebox doors, oven doors, bypass dampers, cleanouts, ash doors, grates and cooktops for the heater you want to build!