God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Satamax Antone wrote:Flames are definitely pulling. So that must rocket.

I have been running it with everything open. Burns everything super fast and you hear that distinctive rocket sound.

I think there is, like you surmised not enough space for exit to the bench. Plus drag from that flexi pipe. To open this up and create new connection would surly help to ensure the bench gets heat and warms.

?

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

thomas rubino wrote:Hey Fraser;

Your 150 mm pipe going to the mass would be fine with a J tube.

With a batchbox, I suggest installing a 200 mm tube instead.

Free flowing that way and I would also use 200 hard pipe in the bell.

The corrugated pipes are known for slowing flow.

My 6" (150mm) batch in the studio flows into an 8" (200mm) piped mass.

I do need and use a bypass to start a cold stove.

Old Weathered builder...

Satamax Antone wrote:I guess, from those pics, that your bench is bypassing, looking at how close the pipes are together.

What i would do, if it was mine, get rid of that flexi pipe in the elbow here

May be make a plenum, a bigger chamber, instead of that. Like that, i would be sure there is no restriction there. Get rid of the flexi pipe inside the bell.

But i would fit an elbow before; in the bell. To lower the height of the cold gases pick up. I call that a plunger tube.

The best explanation if from Gerry.

Here https://permies.com/t/69146/Bell-questions

Even if it is an elbow, what is interesting is to get the cooled gases, and not the hot ones in the case of a low bench. What i was explaining to Gerry there, is that a flare or funnel enlarges the pickup area, so you can lower it even more.

Do do the maths.

A 15cm pipe would have to be at least 5.62cm from the bell's floor. Same calculation as a barrel gap. Or heat riser gap.

If you enlarge the end of that plunger tube, to say 30cm. You have 94.24 cm of circumference.

Then you divide your absolute minimum surface area, which is 265cm² or 1.5x the CSA, by those 94.24cm, and you get

2.81cm from the floor.

I would leave at the very least 3, to avoid problems with the boundary layer.

fraser stewart wrote:

Is it needed to have a pipe pertruding into the end of the bench. I know now not to use flexible. But i mean a normal pipe?

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

1

1

Satamax Antone wrote:Fraser, your pics don't show for me. May be way big ones? Can't seem to fix it either.

Also, i wanted to ask, you're in Scotland?

Satamax Antone wrote:Fraser, your pics don't show for me. May be way big ones? Can't seem to fix it either.

Also, i wanted to ask, you're in Scotland?

Silence is Golden

For all your RMH needs:

dragontechrmh.com

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

4

4

1

1

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com

3

3

2

2

1

1

Silence is Golden

For all your RMH needs:

dragontechrmh.com

1

1

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

1

1

Satamax Antone wrote:I like the slitted tube.

Never used it myself, nor heard of anybody using it before. I had spoken about it before in other posts. But nobody ever replied, or stated that they used it. If it works for you, i'm happy. And you can brag that you"re the first one to officially use it!

How far from the bottom of the bench did you set it at?

What's that mesh with the clayish blobs?

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Satamax Antone wrote:Does the bench starts to warm up?

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

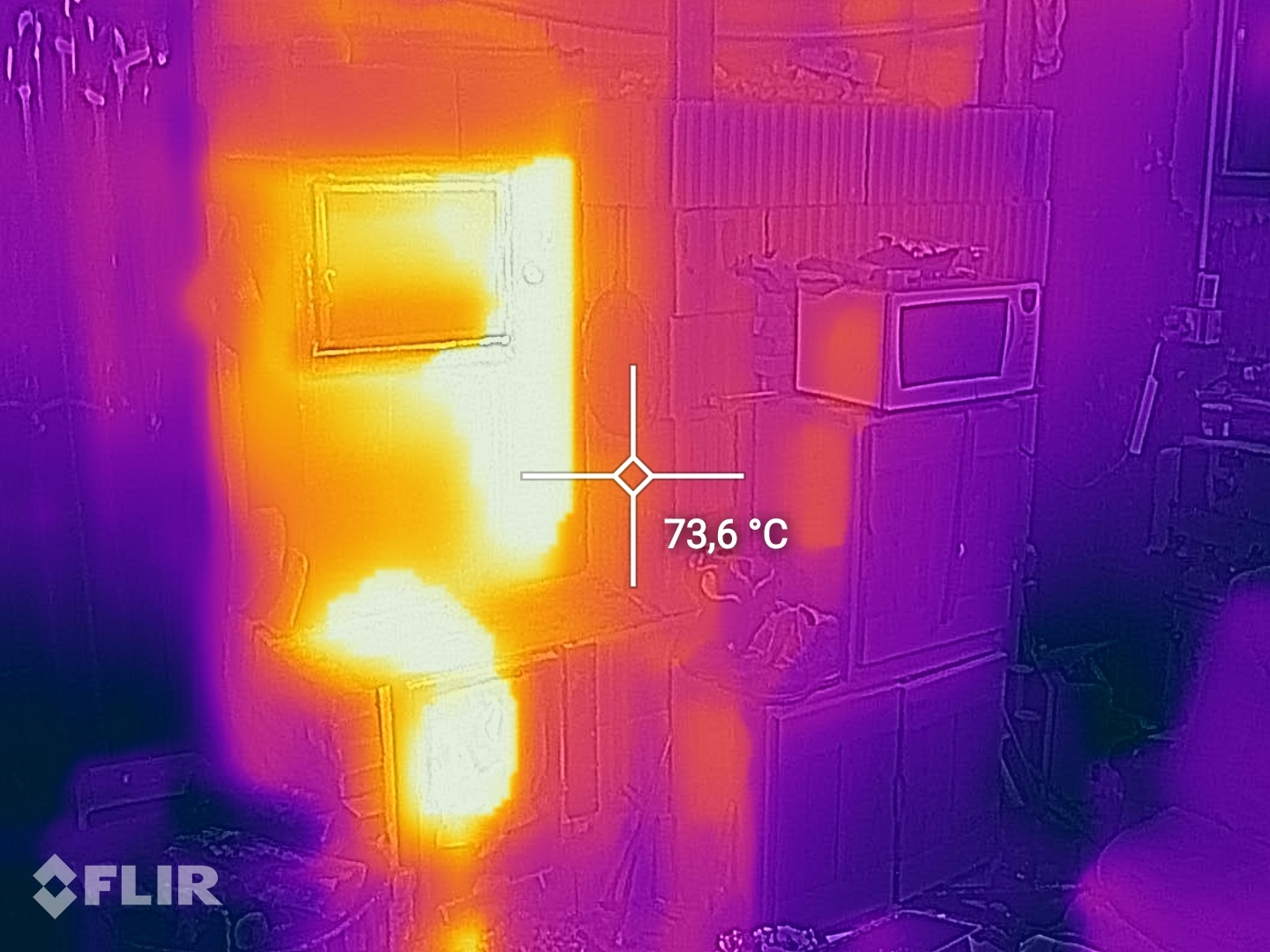

Satamax Antone wrote:Cool, even the end of the L warms up ?

I guess you know, the arrow and round pointer thing on the flir of the S60 (or is it a s61?) serves as a spot temperature "sensor" That would be nice if you could take pics of the hot spots with the temperature showing.

Something like this.

By the way, if you want to see my build. It's here!

https://permies.com/t/44806/Cobbling-workshop-heater-cooktop-oven

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

|

Chris has 3 apples and Monika has 4 apples. With this tiny ad they can finally make a pie!

turnkey permaculture paradise for zero monies

https://permies.com/t/267198/turnkey-permaculture-paradise-monies

|