Hey Mark,

Materials: they have standard sized firebrick in most building material stores. I don’t mind Leroy Merlín, but I think the FB there was expensive. I buy mine at BigMat, Pérez Lázaro or the local “material de construcción”.

Splits might be harder to find. Also I find them harder to stick together. I usually just use clay slip.

ISA, insulation and bell depths:

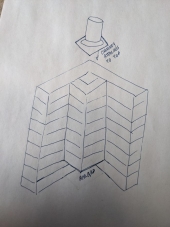

I was thinking whether building a brick chimney against the outside wall, whithin the bell, would be an option to include a bypass, solve connection problems metal/brick and take care of the insulation problem.