Those who hammer their swords into plows will plow for those who don't!

"If you want to save the environment, build a city worth living in." - Wendell Berry

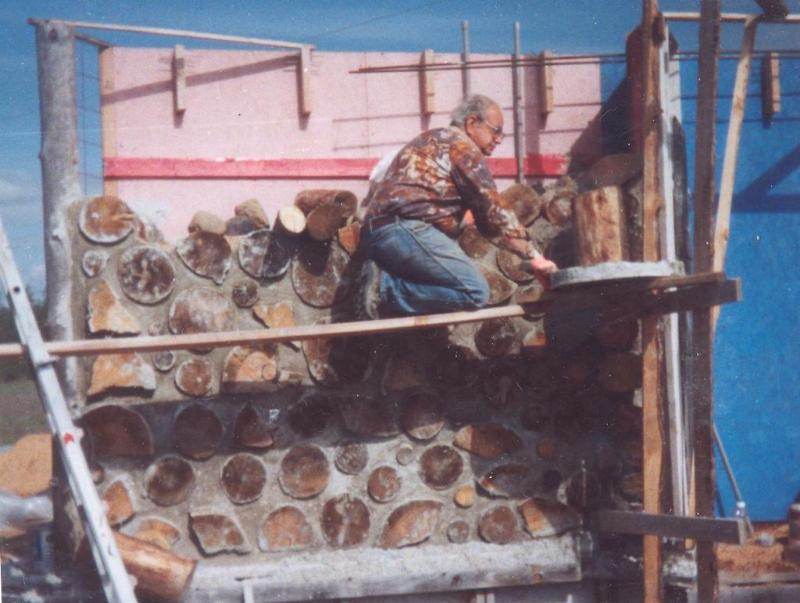

Brian Knight wrote:Do I remember seeing a double layer cordwood wall with an air barrier/insulation in the middle? This is the only way I can imagine cordwood performing well from a thermal and energy efficiency standpoint.

Those who hammer their swords into plows will plow for those who don't!

"If you want to save the environment, build a city worth living in." - Wendell Berry

"If you want to save the environment, build a city worth living in." - Wendell Berry

"If you want to save the environment, build a city worth living in." - Wendell Berry

My project thread

Agriculture collects solar energy two-dimensionally; but silviculture collects it three dimensionally.

My project thread

Agriculture collects solar energy two-dimensionally; but silviculture collects it three dimensionally.

My project thread

Agriculture collects solar energy two-dimensionally; but silviculture collects it three dimensionally.

Just call me Uncle Rice.

17 years in a straw bale house.

My project thread

Agriculture collects solar energy two-dimensionally; but silviculture collects it three dimensionally.

My project thread

Agriculture collects solar energy two-dimensionally; but silviculture collects it three dimensionally.

I have these in my straw bale thread, but I'll share them here too.Cj Verde wrote:pics?

Just call me Uncle Rice.

17 years in a straw bale house.

|

A mime should never say "Look! I'm in a box!" Now watch this tiny ad:

permaculture thorns, A Book About Trying to Build Permaculture Community - draft eBook

https://permies.com/wiki/123760/permaculture-thorns-Book-Build-Permaculture

|