Thank you Glen, Phil, and Thomas for the very helpful replies!!

I meant to reply sooner but was unable to until now.

After reading the replies, I think my plans are much too large for my needs and will be too hot anyway.

I compost, so most of my garbage that I want to burn is plastic.I live alone so I do not create that much trash, but I cannot drive due to an illness and I have about 30 big trash bags of mainly plastic piled up from the past 4 years as I was recovering and moving to my land ( moving seems to generate a lot extra trash for me).

So normally I would not need a huge incinerator but I wanted to make one big enough to handle a full 30 gal trash bag at least .

Maybe its dillusional, but I envision throwing filled 30 gal trash bags in without opening them and watching them easily disappear with little smoke! I know with the right design, that is possible though.

Also I really wanted to use my stainless cloth dryer drum because they are great fire " pits" with not much smoke all by themselves (using wood though) , so I thought coupled with a rocket stove, it would be extra efficient, p!us it's big enough to hold a filled trash bag. Plus using a drum like that would make possible a true downdraft design.

I understand how it might melt though... but my design is a downdraft one ,so my thinking was that the stainless drum would be in the coolest spot of the rocket stove right below the air intake. Like Glen said, the hottest part would be the later part of the burn tunnel and lower riser. So I was thinking that stainless drum would be cooled enough by the incoming downdraft air that it would not get super heated like below it. I like Glen's grate idea but it seems like it might only work at first but then get clogged with smaller particles and cinders after not too long. I cannot really understand it without a pic though. I'm not sure if it would allow for a downdraft design either.

What would happen if I made the burn chamber large enough to hold a filled trash bag ( with or without using the stainless dryer drum), but made the burn chamber and riser a lot smaller in diameter than my plan? That would be much easier to build and also might prevent it from becoming ridicouslouly hot ...but would it still be able to burn up all the smoke up so its smokeless?

I would really like to make something that I can Just through whole trash bag without opening them up and dealing with a big mess. Also , since I live in hawaii, most of the trash is not very dry. I could possibly make a plastic hoop house to use as a solar dryer if absolutely necessary, but I'd really rather not have to dump all my trash out and deal with that mess. Thank you Phil for that info about certain furnaces actually needing wet feedstock to prevent overheating ...I did not know that. So I guess it's possible to make one that handles wet trash.

Glen said "What would be the minimum common size of items in the load? Spacing to hold most of those up would allow good flow around the load"

Most of the stuff is not large ( like plastic meat trays , wrappers, etc. But like I said I do not want to have dump everything out. Does it really need airflow around everything all at once? If I put a whole 30 gal filled trash bag in, the outside parts would get the air first and burn, but the inside would just get hot and smoke and make flammable producer gas which I'm hoping would all just burn up in the burn tunnel. I don't care if it all burns up really fast. I just want it to burn cleanly in the end with little smoke. I don't care if it takes all day to burn up 1 filled trash bag ( though I know it probably won't take that long).

I also have plenty of solar electric power here so if the design I make has insufficient airflow, I could put in an adjustable blower to make an ideal airflow. I thought that also might allow me to use a smaller size burn tunnel and riser. And if my trash is especially wet, I could turn the blower up higher ( and lower if dry).

"Do you have a good quantity of wood or other easily combustible material to sustain the incineration of more problematic or erratic materials? You would want a good clean hot burn going before introducing plastics"

Thank you, yes I have plenty of good coppice wood ( strawberry guava) so that shouldn't be a problem.

Btw, the rock I have here to work with is volcanic porous basalt. Its melts at 1200 c I believe. Its also a bit insulating I assume just because of the many small holes. I'm planning on using store bought refractory mortar but then I want to line the inside with a refractory also ....sodium silicate ( waterglass) made from kitty litter and lye .

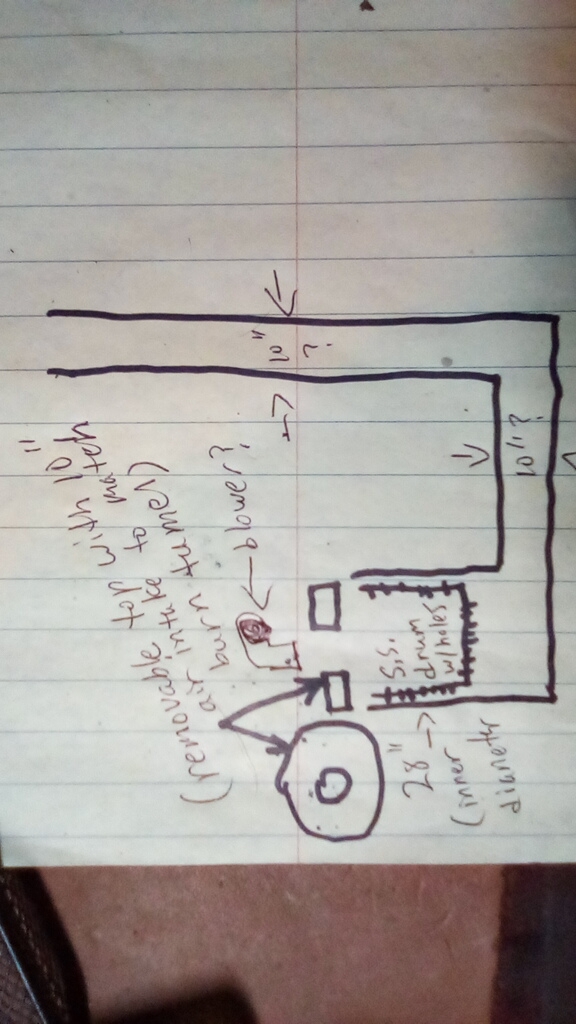

I attached another diagram with a modified design like I just talked about. I don't know if it will work good or not. Its got a removable lid with a hole the same size as the new smaller size burn tunnel .And also a blower if necessary. To sum my goa!s again : throw in full 30 gal bag if mainly plastic trash not fully dry and make it disappear with little smoke

(I also have plenty of wood to help)

Thanks again for the helpful input!

Pete

7

7

7

7

12

12

9

9

3

3

3

3

(I also have plenty of wood to help)

(I also have plenty of wood to help)

2

2

I was recently thinking about a similar idea . But instead of burning all the gasses up inside the riser area, the tube could go to the outside and bubble up through some water to cool/ clean it and collect in an upturned tank .....like a methane digester setup. And then it could be used as fuel for cooking stoves, etc.

I was recently thinking about a similar idea . But instead of burning all the gasses up inside the riser area, the tube could go to the outside and bubble up through some water to cool/ clean it and collect in an upturned tank .....like a methane digester setup. And then it could be used as fuel for cooking stoves, etc.