posted 12 years ago

Insulated burn chambers definitely burn hotter and cleaner - which tends to increase your heat output per wood.

I like the water bath idea. Another option we've seen (less controlled) is putting some bricks between the hottest part of the flame and the center of the pan. Might be able to combine the two.

My impression is you need quite a bit of heat. Dry firewood only contains so many BTU per pound, so if you build a small burner you are limited on how fast you can feed wood into it. If you are used to burning wheelbarrows full of wood, you will need a lot less with this method because of less waste, but you don't want to get too small.

I'd say a 6" stove would be a pretty good size to start. With serious insulation, you can get enough heat to boil 4 gallons of water in under 20 minutes. With moderate insulation, you might be looking at longer times and less fuel efficiency.

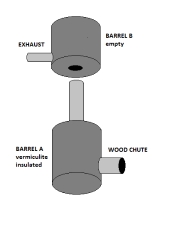

You could also do an 8" stove; this size tends to fit well in a 55-gal drum, which gives you 23" diameter of support for your larger pans. and it will burn more wood at a time, and may be able to do longer steady burns because you can load a larger piece of firewood. When built with brick, the firebox stays hot enough that it can often burn a log on its own coals; but 2 or 3 chunks is a little more reliable for a long, steady, clean burn.

I tend to build my stoves out of portable bricks, rather than trying to make the whole stove portable as a unit. A brick stove can also be left on site from year to year, for example in a little 'sugaring shack'.

For a very portable version, you might look at something like our Poor Man's Forge / Cooking / Canning stove. We did this in the October 2012 Missoula workshops; it's on the "Hot Rockets" DVD that Paul Wheaton released last summer. It's built into a small barrel, with high-grade refractory insulation and perlite/brick. It was a prototype and could use some better workmanship to make it more durable, but the performance was spectacular.

Yours,

Erica W