mekennedy1313 wrote:, the "house" is compromised in very cold climates. Floors buckle, plumbing bursts, frost heaving destroys foundations etc Cold, by itself can be very damaging because of the differential rates of contraction of different materials including woods of different species.

paul wheaton wrote:

A) conductive heat is far more efficient than convective heat. A person can be sitting in a room where the air temp is 40, and the seat temp is 100 and they are perfectly comfortable.

B) radiant heat is far more efficient than convective heat. A parabolic radiant heater can be directed at a person and they feel perfectly warm even though the air temp is 40.

paul wheaton wrote:

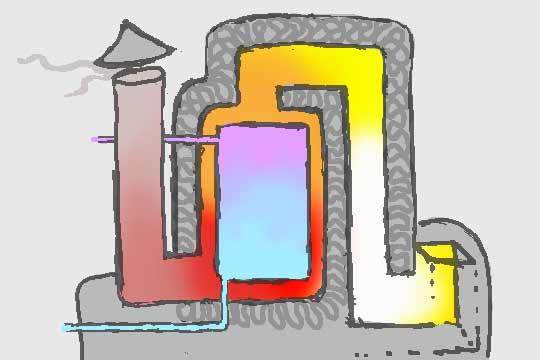

6) Due to the exhaust of a rocket mass heater being near room temperature, I think it is safe to say that a rocket mass heater is 95% efficient - maybe more.

paul wheaton wrote:

So when we take point 7, and then mix in A and B, we end up with somebody being able to be comfortable all winter with, perhaps 99% less wood burned.

True?

paul wheaton wrote:

Anything I left out?

find religion! church

kiva! hyvä! iloinen! pikkumaatila

get stung! beehives

be hospitable! host-a-hive

be antisocial! facespace

) Us Hipnecks measure at the seat of the pants (so to speak) by whether it's ok to take the socks off or not, how many cords of wood did I cut and haul this year and so on.

) Us Hipnecks measure at the seat of the pants (so to speak) by whether it's ok to take the socks off or not, how many cords of wood did I cut and haul this year and so on.

Build it yourself, make it small, occupy it.

Donkey wrote:Passive solar heating rocks..

find religion! church

kiva! hyvä! iloinen! pikkumaatila

get stung! beehives

be hospitable! host-a-hive

be antisocial! facespace

paul wheaton wrote:

Anything I left out?

paul wheaton wrote:

True?

Anything I left out?

Professor of Thermal and Electrical Engineering, Welding/metallurgy: Licenses: PE license, Mechanical license Variety of other "certifications" from industry groups such as Refrigeration Service Engineers Society http://www.rses.org/, ASHRE http://www.ashrae.org/ Ect.

It can be done!

Birdman wrote:

and that is the comparison right there one stove used 8 units of wood and one uses 1 unit of wood to heat the same area and building,

if all is the same, building and no upgrades, then the RMH is 8 times more efficient than the one taken out,

Professor of Thermal and Electrical Engineering, Welding/metallurgy: Licenses: PE license, Mechanical license Variety of other "certifications" from industry groups such as Refrigeration Service Engineers Society http://www.rses.org/, ASHRE http://www.ashrae.org/ Ect.

paul wheaton wrote:

The reports are pretty universal. People are heating their homes with much less wood. And then we have another group of people who are saying that it cannot be so.

Are there efficiency numbers available for stoves where the damper is low, or wet wood is used?

Professor of Thermal and Electrical Engineering, Welding/metallurgy: Licenses: PE license, Mechanical license Variety of other "certifications" from industry groups such as Refrigeration Service Engineers Society http://www.rses.org/, ASHRE http://www.ashrae.org/ Ect.

Build it yourself, make it small, occupy it.

Donkey wrote:

What is it that makes me comfortable?

Professor of Thermal and Electrical Engineering, Welding/metallurgy: Licenses: PE license, Mechanical license Variety of other "certifications" from industry groups such as Refrigeration Service Engineers Society http://www.rses.org/, ASHRE http://www.ashrae.org/ Ect.

Professor of Thermal and Electrical Engineering, Welding/metallurgy: Licenses: PE license, Mechanical license Variety of other "certifications" from industry groups such as Refrigeration Service Engineers Society http://www.rses.org/, ASHRE http://www.ashrae.org/ Ect.

Professor of Thermal and Electrical Engineering, Welding/metallurgy: Licenses: PE license, Mechanical license Variety of other "certifications" from industry groups such as Refrigeration Service Engineers Society http://www.rses.org/, ASHRE http://www.ashrae.org/ Ect.

Build it yourself, make it small, occupy it.

Donkey wrote:

Little success in heating water.. But NOT none!

Professor of Thermal and Electrical Engineering, Welding/metallurgy: Licenses: PE license, Mechanical license Variety of other "certifications" from industry groups such as Refrigeration Service Engineers Society http://www.rses.org/, ASHRE http://www.ashrae.org/ Ect.

Professor Rich wrote:

10 gallons of water taken from 60 to 120 takes 4800 btu's of heat or about 5/8 of a pound of wood burned. Since no where near all the heat goes into the water it is fair to say that likely takes 1 pound to get it done.

I am fairly sure we could rob from peter to pay paul with one and have a fairly productive unit but there are better methods for water heating.

Build it yourself, make it small, occupy it.

Donkey wrote:

True, not ALL the heat..

But when built in bell stove fashion with the tank in the bell and the chimney at the bottom, it's probably one of the finest wood heated hot water system I've seen yet.

I live in the heart of what was the "back to the land" movement in California during the late 60's early 70's. The remnants of every half-baked hippiefied backwoods water heating contraption EVER contrived litter the hills here and some of them (even) still work. This IS the home town of the Blazing Showers company (check out old original Mother Earth Catalog they're in there) after all..

Anyhow, I've got quite a bit of experience with wood hot water contraptions and this one (IMHO) sits on the top of the heap. I think it might surprise even you, Prof..

find religion! church

kiva! hyvä! iloinen! pikkumaatila

get stung! beehives

be hospitable! host-a-hive

be antisocial! facespace

Donkey wrote:

I think it might surprise even you, Prof..

Professor of Thermal and Electrical Engineering, Welding/metallurgy: Licenses: PE license, Mechanical license Variety of other "certifications" from industry groups such as Refrigeration Service Engineers Society http://www.rses.org/, ASHRE http://www.ashrae.org/ Ect.

Build it yourself, make it small, occupy it.

Donkey wrote:

Heat transfer fluids are, for the small scale tinkerer, more hassle than they're worth. They also take us back into some of the (non-dangerous) drawbacks of coil systems.

Professor of Thermal and Electrical Engineering, Welding/metallurgy: Licenses: PE license, Mechanical license Variety of other "certifications" from industry groups such as Refrigeration Service Engineers Society http://www.rses.org/, ASHRE http://www.ashrae.org/ Ect.

paul wheaton wrote:

a lie.

I do not think that Ernie, or the others, are liars. If nothing else, I don't see any motivation to lie about it.

If neither of these is accurate, then I would very much like to understand why they are not accurate. That might help me to get onto a different path.

Professor of Thermal and Electrical Engineering, Welding/metallurgy: Licenses: PE license, Mechanical license Variety of other "certifications" from industry groups such as Refrigeration Service Engineers Society http://www.rses.org/, ASHRE http://www.ashrae.org/ Ect.

Build it yourself, make it small, occupy it.

Professor of Thermal and Electrical Engineering, Welding/metallurgy: Licenses: PE license, Mechanical license Variety of other "certifications" from industry groups such as Refrigeration Service Engineers Society http://www.rses.org/, ASHRE http://www.ashrae.org/ Ect.

Build it yourself, make it small, occupy it.

ytram wrote:

Does any one know what insurance companies think of these designs?

ytram wrote:

Good information here.

Does any one know what insurance companies think of these designs?

Build it yourself, make it small, occupy it.

Professor of Thermal and Electrical Engineering, Welding/metallurgy: Licenses: PE license, Mechanical license Variety of other "certifications" from industry groups such as Refrigeration Service Engineers Society http://www.rses.org/, ASHRE http://www.ashrae.org/ Ect.

Professor of Thermal and Electrical Engineering, Welding/metallurgy: Licenses: PE license, Mechanical license Variety of other "certifications" from industry groups such as Refrigeration Service Engineers Society http://www.rses.org/, ASHRE http://www.ashrae.org/ Ect.

Professor of Thermal and Electrical Engineering, Welding/metallurgy: Licenses: PE license, Mechanical license Variety of other "certifications" from industry groups such as Refrigeration Service Engineers Society http://www.rses.org/, ASHRE http://www.ashrae.org/ Ect.

|

Too many men are afraid of being fools - Henry Ford. Foolish tiny ad:

The new kickstarter is now live!

https://www.kickstarter.com/projects/paulwheaton/garden-cards

|