Here's what the (running) mockup of my system looked like in the driveway...

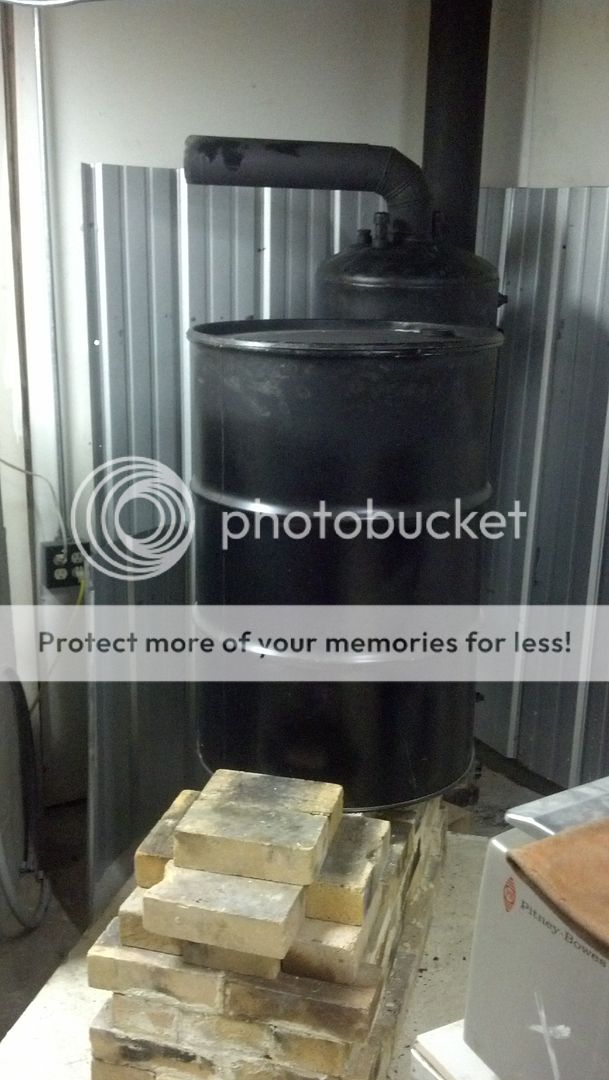

And the final install in the garage:

The system runs like a champ, but there's still a tiny bit of room for improvement...the final exhaust pipe is still probably a little hotter than it needs to be. I can put my hand on it and not get burned, but I don't want to keep it there for more than an instant. Never seem to get any smoke at all...there's a little steam as the system heats up, but that's it. The weird looking horizontal pipe is going to have a blower hooked up to it shortly to make a "heat scavenger" for lack of a better term. The water heater still has the original flue pipe in it (it was gas fired) and the swirly heat exchanger inside. Originally hot flue gas heater the water, but I'm going to make it run in reverse--force room air down the heat exchanger so the hot bell will heat the air...then it will exit the bottom of the bell at the old burner location and go out into the room... I'm hoping to get my EGT down...on the (small) chance that I'm able to scavenge enough heat to cause a draft stall, I can put a speed control on the blower. Given that it probably won't get over freezing until next year, it's probably not going to be an issue no matter how much I cool the bell off...

Makes for kind of a funny looking machine though. It's a nice aesthetic if you like your place to look like you have part of a steam locomotive in it lol. It's in the garage, so whatever. I actually kind of like the industrial look out there.