2

2

TenFires

Satamax Antone wrote:So, Mike, a bell can store heat for some time, even if there's barely any mass. Not long, but two or three hours is not out of the question.

About bells.

http://www.stove.ru/index.php?lng=1&rs=16.

If you have a massonry wall in the house, you could heat it with one side of the bell. If made square like old home heating fuel tanks, or agricultural fuel tanks.

Here you can see the double barrel bell on Peter van den Berg horizontal batch rocket.

http://www.youtube.com/watch?v=tpsGO9tY8rY

May be you could make something like this. Two stacked barrels on your rocket. No worries about the barrel gap then. Plus two stacked barrels, like this, aside the rocket, aranged as a bell. Vertical bell, with intake and exhaust at the bottom, and which would store and extract heat from the flue gasses. Then, you could use a little mass around the second set of barrels, to keep warmth a smidge more.

Myself, i'm on the track of using square tanks, and covering theses with bricks, dry stacked. Whenever i can find tanks which i like.

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

TenFires

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

TenFires

In other words: why run pipe through the bell rather than running pipe TO the bell, then FROM the bell at the other end?

www.dragonheaters.com

http://blog.dragonheaters.com/

TenFires

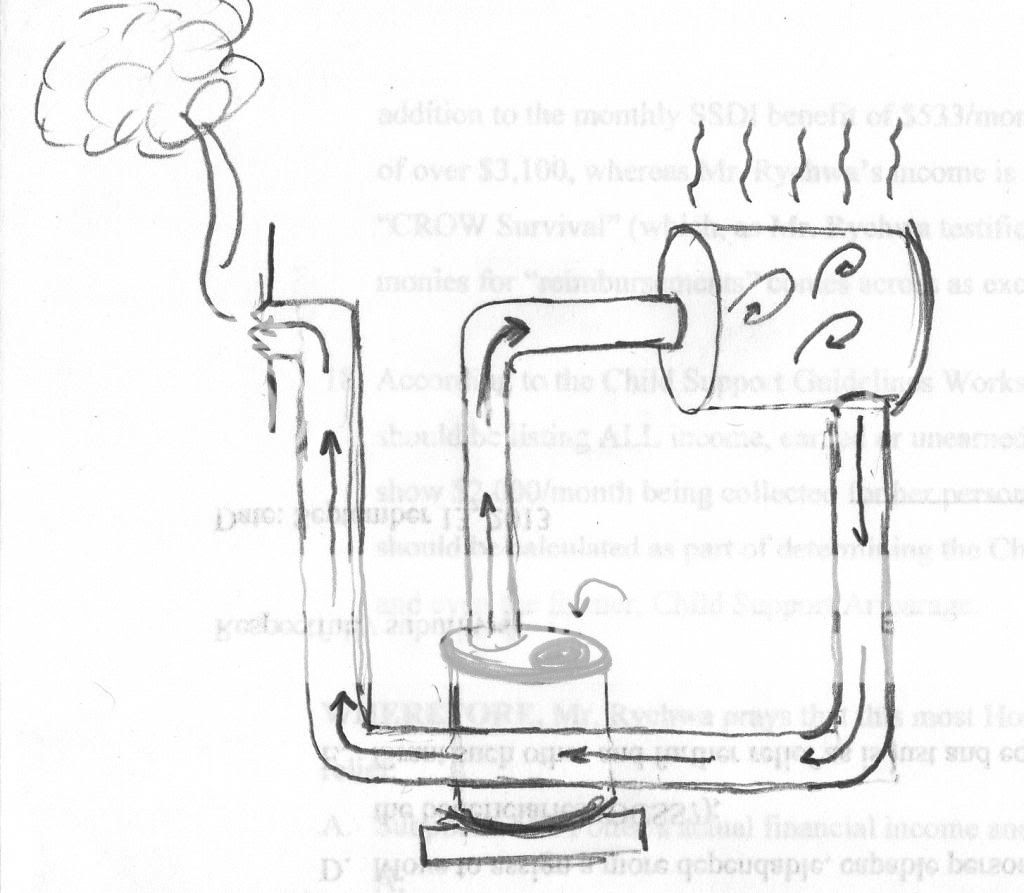

![Filename: Draft1-1.gif

Description: Exhaust extended to bottom of barrel [Thumbnail for Draft1-1.gif]](/t/28865/a/11926/Draft1-1.gif)

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

TenFires

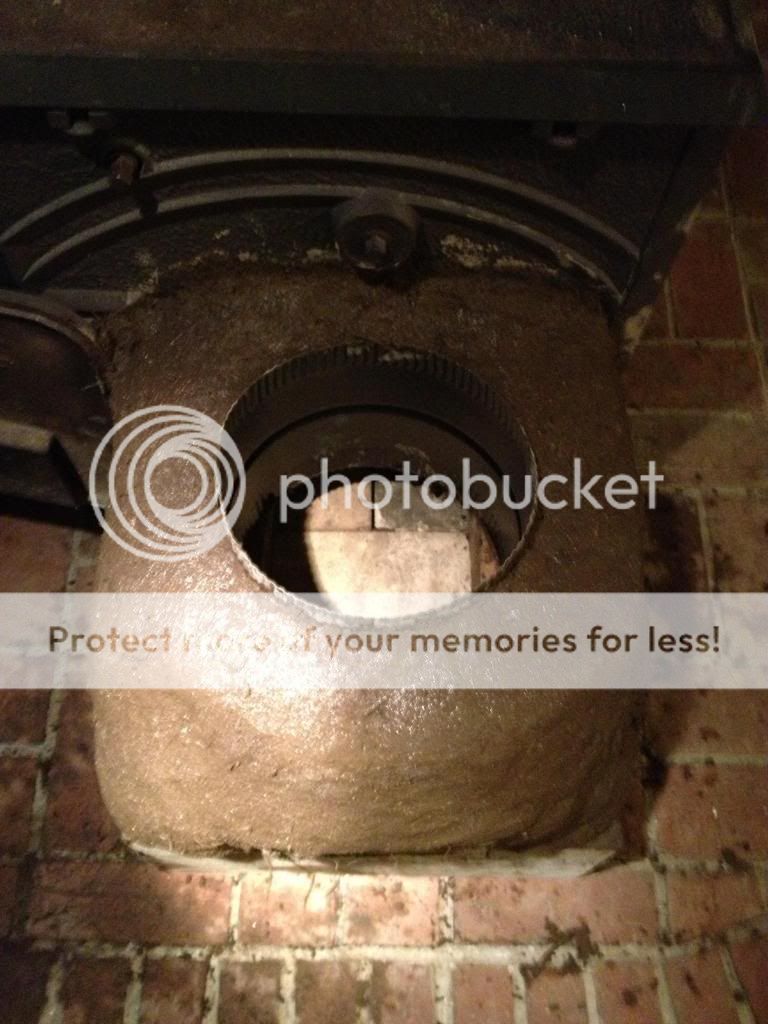

![Filename: Draft1-2.jpg

Description: Insulated feed tube, insulated base [Thumbnail for Draft1-2.jpg]](/t/28865/a/11932/Draft1-2.jpg)

TenFires

Jeff Rychwa wrote:

What to do??

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Nothing ventured, noting gained ! Big AL

Nothing ventured, noting gained ! Big ALSuccess has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

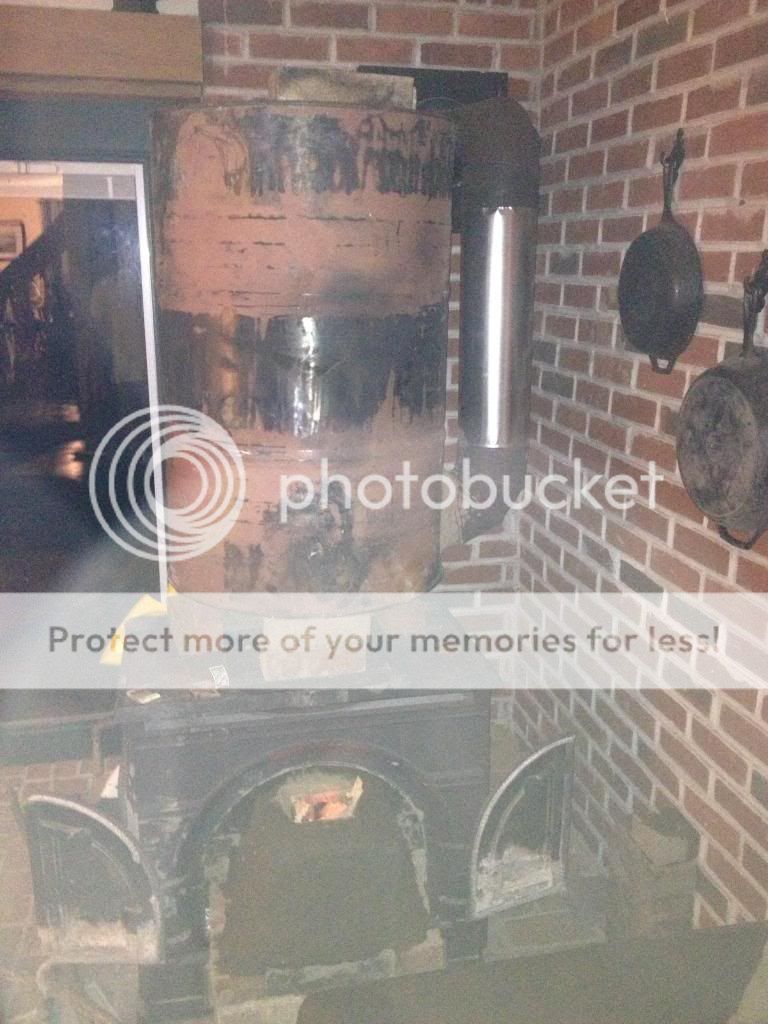

![Filename: Draft1-6.jpg

Description: [Thumbnail for Draft1-6.jpg]](/t/28865/a/11941/Draft1-6.jpg)

Mike Kelly wrote:Allen Lumley : Is this close to what you have in mind?

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

TenFires

TenFires

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

TenFires

1

1

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

TenFires

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

a row of 6" pipe right off the riser up and down with a bunch of 180 degree joints (about 20' worth)

www.dragonheaters.com

http://blog.dragonheaters.com/

TenFires

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

TenFires

"You must be the change you want to see in the world." "First they ignore you, then they laugh at you, then they fight you, then you win." --Mahatma Gandhi

"Preach the Gospel always, and if necessary, use words." --Francis of Assisi.

"Family farms work when the whole family works the farm." -- Adam Klaus

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

TenFires

Success has a Thousand Fathers , Failure is an Orphan

LOOK AT THE " SIMILAR THREADS " BELOW !

| I agree. Here's the link: http://stoves2.com |