- Glenn -

The Troglodyte wrote:

Round is sound but if comprised of separate pieces of wood and all are not tightly forced together then it is not as sound as a properly braced engineered rectangular structure. Mike paid an engineer to design the square or rectangular modules, so you can trust that they are safe. You could use the rectangle or square free standing structure for the roof then put a round cob house walls under it. That would be pretty sound.

Ok, so round at this point without someone in the know would not be advisable.. i am fairly new to the Cob idea due to the prefrence of an underground dwelling, but i have looked at it a bit over the last few days when i seen it used with the rocket stove idea, and it does seem a decent idea but if im going to go to the trouble of building underground we better do it as buy the book as possible

Steel could be safe but then you would be the one who had to pay for the engineering. Normally engineers take jobs like that on a one at a time basis so you would not be able to change or reuse it with their blessing. I have seen concrete and steel for a small u-house priced at around 1.5 million dollars... a bit steeper than Mikes $50 house.

hehe whats this Engineer thing you speak of, those must be very smiler to the code officers i hear about that live in other areas of the world, they must have been hunted to extinction and replace with some other worthless animal like a armadillo here

So with steel i would only be taking my own life in hand, which done with a relativity high percentage of success is ok by me.... so i'll keep at this one

I do not agree with setting the posts i the ground either as the three I charred and bagged rotted off i about three years. I go with a 3/4 concrete stake driven into the ground about 2 feet and about 2 inches of concrete over a plastic vapor barrier about a foot square or so. Leave about 8 inches of the stake sticking out of the ground - drill the post - set it over it. Temporary brace the structure until EVENLY backfilled on both sides.

Hum, that would be much easier than my plan, how has that worked out for you and how bad are termites in your neck the woods.?

- Glenn -

- Glenn -

"the qualities of these bacteria, like the heat of the sun, electricity, or the qualities of metals, are part of the storehouse of knowledge of all men. They are manifestations of the laws of nature, free to all men and reserved exclusively to none." SCOTUS, Funk Bros. Seed Co. v. Kale Inoculant Co.

no more than 2' be ok.? say 26x26 hole or just barly enough room to fit the boards and plastic in say 6".?

no more than 2' be ok.? say 26x26 hole or just barly enough room to fit the boards and plastic in say 6".?

- Glenn -

The Troglodyte wrote:

I would still use the clay rather than the sand if you can take out the big chunks. Sand has no hope of supporting itself at all. The clay if it encounters wet and dry will glue back into a rather self supporting mass. That is what I find here. The cardboard or tarpaper can protect the membrane from the chunks falling against the plastic or EPDM. You could leave the cardboard tight against the plastic and backfill against it. When you backfill do not compact it - let it settle naturally. Do it evenly both sides so as not to knock the structure sideways. Ok roger on the clay sound like a plan, would rather use cardboard as tar paper at lease cardboard dosent stink to high heaven when you messing with it

Insulation from the ground is not necessary since the ground is closer to the temperature you want to maintain anyway, unless you have very deep frost

a quick question about this. during the winter dosent the earth suck the heat out of your UG structure.? something to do with thermal mass and equalizing temperature.? or something like that, sorry its been awhile since ive read up on it or am i thinking something else.?,

in which case a good layer of mulch over the top will be better insulation. Since mulch can burn a layer of soil is still necessary. I'd use the cardboard to protect the plastic when back-filling. In the ground the winter will soak the cardboard anyway making it rather useless as insulation. It's properties would then be similar to the surrounding soilany ideas on the insulation value of mulch? and would sawdust pose to much of a risk.? i know sometimes it can spontaneous combust in sawmill piles.

6" is much better than 2 feet. Quick question here with 6" pf space do you have trouble keeping your board from falling due to not being nailed or can you nail them still. of course if i use plywood i'll need to adapt things a bit, maybe using liquid nail to hold them in placeThe more you have loose the more weight there is against the walls as you are backfilling.

I sometimes use 1 1/2 inch expanded metal screen with a frame to screen out rocks with my Bobcat. If you have machinery it is easier to break the clay chunks down into small enough size for backfill

i have some machinery mainly a front end loader and tractor for this i hope

im also intrested in some of the Cob work you have done, im thinking of building a rockets stove covered with it for this UG house

im also intrested in some of the Cob work you have done, im thinking of building a rockets stove covered with it for this UG house  and if i enjoy that maybe go ahead and do the floors with it, can you make cob bricks.?

and if i enjoy that maybe go ahead and do the floors with it, can you make cob bricks.?

- Glenn -

The Troglodyte wrote:

The tarpaper pretty much changes to just a brittle fiber after being buried a year or two, as the clay sucks the oils out of it anyway, although cool and undergroujnd, it doesn't have much if any smell. Ok Trog i will take your advice on this in the absence of a better way of doing it

Sucking out heat --- not really. It is more of a thermal flywheel effect, so things are slow to change. Think of the house as already being half warmed up because of the soil. Say if its 55 or so in the ground, then you only have to bring the temperature up about 15 -17 degrees to be comfortable. If you are in an above ground house and the temp drops to 20 you need to bring the temp up around 50 degrees, not only of the air inside but the walls, ceiling and possibly the floor if not on a slab. The u-house is generally much easier to heat. We use about 1 1/2 cord of wood per year keeping opur main living area heated.

ok i'll read some more on this, but i have a better idea of what your saying now

I don't know the insulation value of mulch but we have a forum member that uses it for insulation in upper Michigan and it works well for them. I would keep sawdust to thinner layers and alternate it with soil. Just my opinion there. Mulch will be much better insulation than soil though

ok on this mulch idea...can it replace the soil exept for a few inches on top and bottom? and if so how much would this reduce the weight load? and possibly allow me to use a smaller diameter lumber for roof girders.? my trouble isent in getting the wood, its the size of the wood thats the trouble about the best i can get is 8X8s in red or white Oak, also does green wood make much diffrence in building this way.? .

I used the occasional nail but mostly just propped the board with a chunk of soil or rock then put loose fill in a pile as req'd to hold the board in place. We haven't had any problems with the walls. You will work out methods as you get to hands on working with it.

Machines help a lot. A front loader would be a great help.

I don't mind answering questions for someone who is doing something with the information, and helping themselves. I hope you will also share your knowledge.

We have a young man and family on the CP forum that has put a rocket stove in a cordwood house in U.P. Mich.

Here is a link. http://countryplans.com/smf/index.php?topic=2410.0

Cob Bricks would be adobe bricks but possibly with added sand. Sometimes clay without enough sand is mixed with straw to make adobe bricks. Adding sand makes the bricks more durable and harder. The ideal mix of clay and sand for earth building is about 30% clay 70% sand - plenty of straw so there is some in every handful. Any aggregate in the clay has to be included in the 70% also. Mine works out to about 50/50.

That does not mean that you cannot use just clay and straw. The bricks allow more shrinkage and the straw is reinforcement. Using what you have may mean that methods have to change or you need to import some materials to make things the way you want them. Maybe you would have another resource somewhere else on your land to where cost was not so great to import it. The old timers used the natural resources they had available in one way or another usually.

- Glenn -

The Troglodyte wrote:

I would use the cardboard first if you have plenty. I used the tarpaper in a few places thinking I would gain a bit more water proofing advantage. My point is that the tarpaper doesn't give an advantage after I dug it up a few years later but like you, I have rocks in clay and it did stop damage to the 6 mil poly. Ya carboards not a problem i can get it buy the bale if i want to :p

Probably mentioned this but if you can afford it use EPDM over the top and ideally for about 10 feet around. i had actually planed on using EDPM on everything roof, walls , floor, simply because it is so rocky and rough here.

I think I would use a couple inches straw or mulch to protect the EPDM membrane on the roof then about 4 inches of earth, then the second layer of poly over the earth as Mike details, then a bit of straw or mulch covered with earth again - maybe another 4 inches then mulch as you wish. any ideas on how much this would lighten the roof.? or any ideas in General on making the roof lighter and still insulating it well.? could stryro-type insulation be put down or somthing simaler.?

I would try to stay close to the recommended log sizes and keep earth cover to 18 inches or less. I did not have the species of trees mike recommended and even did a bit of eucalyptus. He said nt to fret if you are close to the log sizes as there is a safety factor figured into his charts. You can also use his rectangular or square beam sizes rather than logs. That is what I am doing on one for a friend as we have all big logs rather than small. ok i'll do some more studying on this also i might could do the 10'6" spans with 7' between posts, i'll check with my local mill and see how big the usual beams they cut are and price them, steel still might be cheaper in the end, aint that sad

- Glenn -

i was thinking if i can lighten the load of the roof enough and have a minumum of dirt on top just enough to allow shallow rooted plants to grown, 8x8s for the post spaced 4' apart, 8x8 beams every 2' and using 2 8x8s for roof girders and internal post if possible stretch the span to 12 feet to removes as many post as possible internally, this may be to big of a gap o do thats why i was hoping straw bails might work some way. your thoughts...The Troglodyte wrote:

Good on the cardboard and EPDM On cardboard i worry about termites should i be.? or am i being over cautious.?.

Soil weighs about 100 lbs per cu ft. Straw weighs about 3 lbs per cu ft.

Mulch weighs about 20 lbs per cubic foot. Water weighs about 62.4 lbs per cu ft. Roof weight will be a combination of these. Estimate your mix and multiply it out. do you have any thoughts on the use of straw bales for a roof.? this seems like it could provide insulation and also weight savings needed any ideas on

Yes - you could use insulation board covered with soil for fire protection and then mulch if you like to cut weight. No problem - use the waterproof type if exposed to the water or alternatively put it over the wood under the membrane.

Study the charts in the book. Cutting the spans in half could cut the girder size. You could also use built up beams - ie: 2x10's etc nailed together to make a beam of the size you need - alternate nails top and bottom every foot or so. Splices are allowed. CP forum has some details if you do a search there - for built up foundation beams. Same info will work for this.

- Glenn -

The Troglodyte wrote:

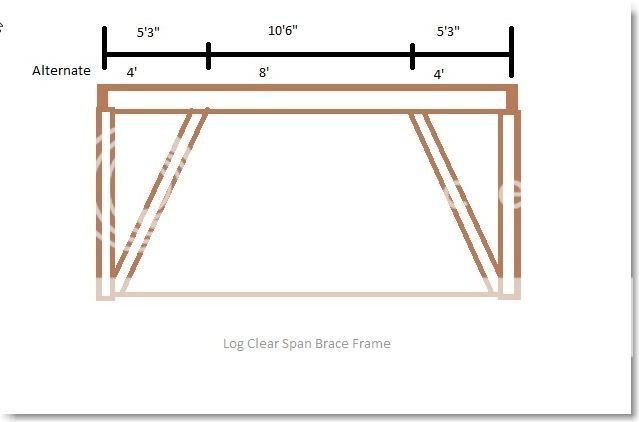

I try not to deviate much from the engineered plan just to keep from sticking my neck out but I have made a way to get rid of a center post keeping the span as engineered. I make a brace frame keeping the unsupported span as engineered but take half the load to each side next to the other frame posts. This may require a footing to take the extra weight. I am not an engineer and most engineers would not want to put the load on the ground that the normal u-house has anyway without a gigantic footing. That is where knowing your soil conditions helps. My outriggers on my crane indicated to me that my soil would safely support the loads without additional help such as big footings.

Here is the way I move the load from the center post to each side.

Glen thats a very cool idea what kind of soil do you have where you are ? the ground here just a few inches down tends to be red clay mixed with cans stone usually very hard and when dry almost rock hard

This way still keeps the unsupported span to one of the engineered sizes from the book. Half of the load from one span is transferred to each side though.

- Glenn -

Glenn Kangiser wrote:

Thx, Cyric30

My ground is similar - clay and rock.

I consider mine claystone - a backhoe scrapes about 2 inches per scrape. I consider mine capable of supporting about 60000 lbs psf actual load. With 18 inches or so earth you should have under 10000 lbs on a 7 inch round post per my calcs. You could put a concrete pier with rebar in it if you need more load capacity however in my experience it has not been necessary. If your clay gets wet and softens that could be another story.

I find that mine will only turn soft after pulverizing it with machinery and adding water - then it goes back to very hard. It is a mineral clay as opposed to an organic clay.

I find that mine will only turn soft after pulverizing it with machinery and adding water - then it goes back to very hard. It is a mineral clay as opposed to an organic clay.[color=Green]Ok Glenn im going to study on this some more and do some more figuring and pricing, but i still believe this is the cheapest way to build an underground house. so im going to keep at this till i get a good plan, i'll probobly have a bunch more questions over the next few weeks, maybe months, but i hope they will lead to a problem free build for meso thank you again for all your help so far

- Glenn -

- Glenn -

|

Live ordinary life in an extraordinary way. Details embedded in this tiny ad:

permaculture thorns, A Book About Trying to Build Permaculture Community - draft eBook

https://permies.com/wiki/123760/permaculture-thorns-Book-Build-Permaculture

|