God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Tys Sniffen wrote:I've googled for a while now, and still don't get the specifics of what a batch stove is, and how it would apply.

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

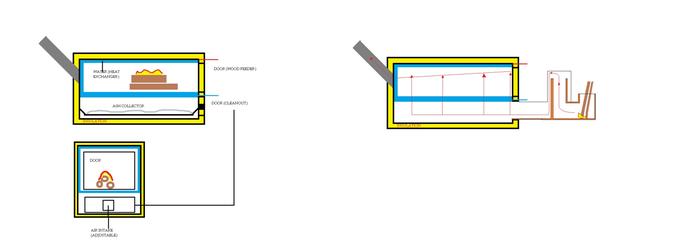

Tys Sniffen wrote:It would seem the 'secret' of this thing is the tiny air INlet, and the tiny air *channel* (Peter Channel??) between the fire box and the vertical riser. Am I understanding that correctly?

Tys Sniffen wrote:and I have seen MANY discussions about dimensions on that site, but can I get a simple 'about this' for a situation where I might set this up to use a 55 gal barrel as the roof of the fire box?

Tys Sniffen wrote:would I suffer by not using mass ? that is, using old scrap barrels rather than brick and cob?

Tys Sniffen wrote:and, I don't seem to see anyone 'cooking' at the top of the riser, but I assume there's a good amount of heat coming out there?

regards, Peter

Tys Sniffen wrote:BUT," the P-channel" - I'm not seeing that in any drawings or photos. that sounds like an air pipe coming from the outside of the box and going into the back of the box?? I see one diagram with a whole 3rd barrel off to the side. is that what that is?

Tys Sniffen wrote:I'm actually thinking about building this right into a trench/fox hole in the ground, as I'm only interested in direct heat to the pan on the riser, rather than mass heating. so If I need to run a separate air pipe to the back of the box, that would mean running a pipe through a different section of dirt? or am I way off?

regards, Peter

| I agree. Here's the link: http://stoves2.com |