posted 9 years ago

I have not attached a bin roof to bags. I have worked with a few bin roofs on bins, bin roof panels as end walls on a bin set up as poor man's Quonset, conical framing with dimensional on bale, reciprocal timber on bag, hip on bags. Domes of all flavors. Plenty of traditional roofs. It's all kinda the same though.

You'll be fine, as you got a contractor buddy, machine and an outer ring. No breeze that day! Some strapping deeper down couldn't hurt on the prevailing wind side, and maybe the other too if you have nightly katabatic winds off the mountain.

I was picking up on your urgency. But It sounds like you know what you need to know. Show you contractor buddy my ripped blocking suggestion at the end of this post.

Also, seems like to have plenty of loft space, depending how deep you'll have it. Low ceilings along walls is for built ins. It'll be nice to work off that for your ceiling/roof.

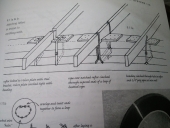

I didn't realize that you were drilling through the panels. That is good. You could even rip lumber on a table saw at the angle matching your bin pitch. Glue and screw them to the top plate, later add hurricane clips. Spray foam would glue it all together even more . Then you could screw panels to those angle ripped pieces directly. You could even plan ahead, making say one angled piece per bin roof section, or whatever number you desired, and if and when you install these run them 1.5" short of the next angled ripper block, including a rafter tail between these angled ripper blocks that could stick inside say a foot, and outside run shy of the end of the panel. That would give you continuous roof pitch angled attachment points on your top plate, and 2x4 stubs inside to sister up rafters next to, and rafter tails outside for fascia, soffit, etc.

Closed cell SPF is going for $.75-1.20 a board foot here in Colorado. A board foot is a square foot 1" thick. your ceiling is about 700 square feet. $1 BF is about standard. If you are super rural and the only rig that will travel to you has no competition, he will probably be at the higher end of that, while the lower end is usually for bigger jobs. My friends bin here in Colorado has 2" I think, and it's rediculous how toasty it is all winter. She never framed/furred out, as in no additional structure, so she'll have to do like the sprayfoam air form domes do, and spray a drywall texture or such and spray a paint.. which isn't a bad route... Or plaster. Another friend covered her spray foam yurt ceiling with an old parachute. Since you are vaulting your ceiling due to the loft, I second you on the closed cell. I'm sure money is tight, but you'll be glad that he sprayed the second or third pass, if he is already coming out, firing up machines, setting up, etc. It's worth it.. He may make it worth your while on a lower board foot cost if you spray a little more. Sell some thing you don't need, sign a payment plan with him, pawn, borrow, cheat, steal, gamble. Get that foam on your roof.

And wrap tarps, billboards, free lumber tarps, etc on your exterior of your bags if you haven't plastered yet. Don't let them sit exposed all winter. And take pictures, I regret only having a couple.