This happened a couple times to me when I was living on the homestead.

This happened a couple times to me when I was living on the homestead.

Jim Garlits wrote:You made the analogy of a mortar and pestle. I think that is apt. What if you added a cylindrical steel pestle into which the mortar fit pretty snugly? Could even put a small sliding door at the bottom to clean out the finer contents at the bottom when you're done smashing. I think that the increased pressure per square inch might yield a smaller, finer output.

) Notice my very expensive "chop saw". This won't cut anything thicker than 3/4" thick or so, and it is very slow. But it was only $25, as opposed to $300+ for an actual chop saw. For my at-home messing about purposes it is perfect.

) Notice my very expensive "chop saw". This won't cut anything thicker than 3/4" thick or so, and it is very slow. But it was only $25, as opposed to $300+ for an actual chop saw. For my at-home messing about purposes it is perfect.

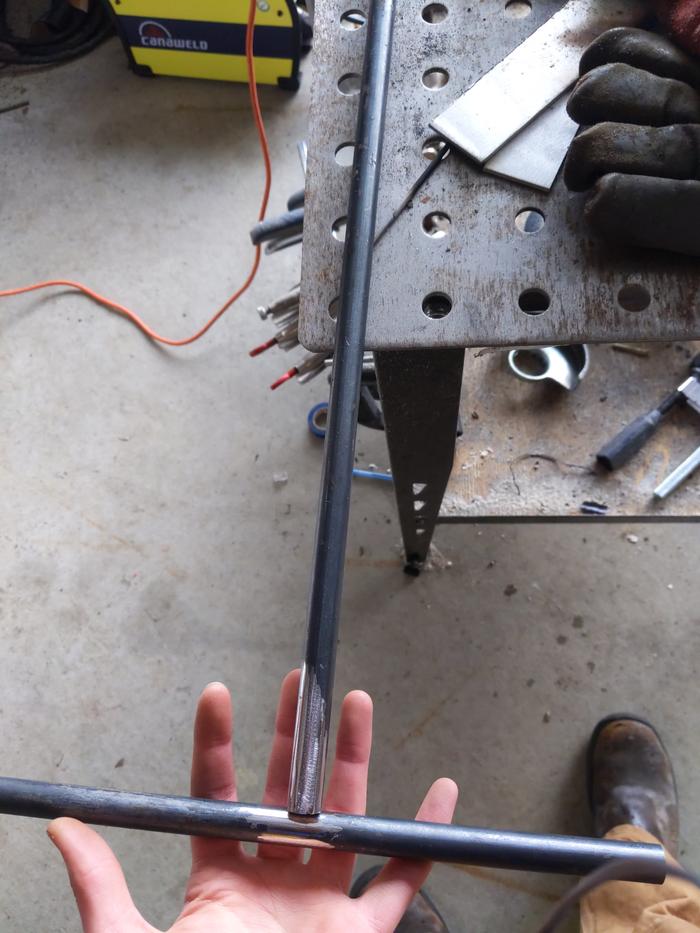

But it just means that after welding, I did a small weld on where my other welds ended. Often, a little divot is left at the end of a weld.

But it just means that after welding, I did a small weld on where my other welds ended. Often, a little divot is left at the end of a weld.

May Lotito wrote:

How heavy is the sledge hammer? I use my sledge hammer for crushing stuffs too. It is heavy at 8 # so I put things on a 1 ft tall tree stump, sometimes with a cardboard box for containing. With this height, I am able tobstand straight up with both hands holding the handle and smash with a up and down motion. It's not hurting my back or wrist this way. I guess if the hammer is light enough with one hand, a knob will work. Otherwise, maybe weld a horizontal bar on top for both hands to hold?

John F Dean wrote:I don’t know how much land you have, but I have a Border Collie and an Australian Shepherd who prefer fresh rabbit to dry food.

She does deter them though when she’s outside!

She does deter them though when she’s outside!

John Wolfram wrote:I'm a firm believer that the best defense against rabbits is a good offense. In the past few months, I've trapped over a dozen rabbits at my property, and my trapping routine will continue through spring. I'm not sure what stores are up in your area, but the Rural King 2-pack cage traps work wonderfully for rabbits, and are only $15 per trap (https://www.ruralking.com/catch-and-release-traps-for-raccoons-and-rabbits-2-pack-87-678-0204).

I also do what I can to get rid of the places that rabbits like to call home. This past summer, I cleared out a bunch of brush and stacked it into piles. Rabbits love to live in brush piles, so I've been getting rid of the piles as fast as I can.

Also, if you use tree guards, make sure they go up at least as high as the rabbits can reach when there is a few feet of snow on the ground. That was an expensive lesson I learned one year.

Derek Thille wrote:

Stefan Sobkowiak has done some videos on this - I think his YouTube channel is The Permaculture Orchard (of course, that may be incorrect...it may just be his name). I like the solution he uses that he got from an old orchardist. Use 1/4" hardware cloth to wrap the base of the tree. The ideal is to cut the cloth so that you have a cut edge down to the ground. This will also deter voles which will girdle a lot of fruit trees as well. You don't need to peg the cloth, but base it upon the size of a mature trunk. Of course, that protects the trunk but won't protect branches / twigs from browse higher up (deer and rabbits / kin if the snow drifts enough.

Derek Thille wrote:This weekend I added another layer of protection around the apple tree in the city I planted this fall. I'd been keeping an eye on tracks and now the snow and hunger got to be enough that the cottontails were able to chow down on a low branch. War was declared, although lethal force would be difficult here in the city as too many would take offence and potentially take some action against me for "cruelty".

Donna Lynn wrote:A few years back, I put 2" x 4" welded wire cages around my brand new fruit trees, quite proud of myself for getting ahead of the rabbits and deer. My cages were 6' tall to exclude both rabbits and deer. Imagine my chagrin when, come spring, a few of my trees STILL had bark chewed off around the bases! I asked an expert and he said: MICE. Mice will eat bark if they get hungry enough. And they can squeeze through tiny openings. So now, in addition to my cages, I wrap my little tree trunks in the white plastic spiral wrap-around stuff that is available cheaply at garden stores or online. They are re-usable until they get brittle and crack. I take them off in summer when critters are less likely to chomp bark, to keep them from hot sun damage as long as possible. I leave the cages on until the trees are tall enough and have tough enough bark to survive deer and rabbits.

The 1/4" hardware cloth mentioned by Cecile is also a good choice for mice and rabbits. And deer too if you make the cage wide and tall enough, but that could get expensive.

Cécile Stelzer Johnson wrote: Oh, Cam, I share your disappointment... and I am going to take a serious look at my trees.

The only thing I have found very effective is to surround the tree with a 1/4" hardware cloth that is as tall as the snow cover... plus a little more. In a couple of years, you may retrieve the hardware cloth and re-install on a young tree. Once the bark gets furrowed, rabbits will not longer be attracted to it.

I did try these perforated plastic guards they sell, but to no avail: moisture got between the plastic and the tree and caused a rot, so no more plastic for my trees.

Then I became more creative and smeared the trunk with Wasabi. [I was fighting a racoon away from my bird feeder then, but it could work for rabbits]. The racoon stayed away... until we had a good rain.

For the ones that can be salvaged, if you are good at grafting, you could try a bridge graft, although I am not sure you can save the one that was badly wounded.

Cécile Stelzer Johnson wrote:You might think that 6 ft isn't tall enough and a deer could jump it. True. But one thing about deer: they are lazy. And if they can browse plenty outside, they won't come in. I had one that panicked during hunting season and jumped over it, found itself trapped inside the orchard. It walked around for a while trying to find an escape. so I went outside in my orange suit and screamed and yelled... and panicked it right outside the fence. So yes. They *could* jump it. They opt not to.

Cécile Stelzer Johnson wrote:Donna is correct: It is mice that can get through small holes and will chew the bark and girdle trees. Rabbits and hares have not given me that much trouble. I should say that there is a forest, so if they need to gnaw on something, they do not need to get at my trees. Besides, in the orchard, I think they feel a bit exposed, so they don't pass through the fence [the little ones could, actually]. That's why I opted for the 1/4" hardware cloth. I use the 2 ft high. It is more than enough for mice, even with deep snow: they tend to tunnel on the ground, anyway, between the ground and the snow, so I probably could get away with the 12" high and make it just tight enough that they cannot get between the tree and the hardware cloth. I have also used sections of black ABS pipe, the corrugated stuff they sell in 50 or 100 ft. length for drainage. Sometimes, it is even perforated.

I cut it to length, then split it on one side and wrap it around the tree. It worked well enough, but when came the time to remove it, it was so stiff that I damaged the bark, so now, it is hardware cloth. I must say, I have not had good luck with the white plastic tree wraps they sell for that purpose. The rain and snow got trapped in it and when I watered, too, it didn't dry. I didn't notice it right away but I lost a couple of trees to that.

So welded fence for the deer, hardware cloth for the mice.

I can say for certain I never thought of putting manure on the trunk to deter critters. And pee too? It does make sense, I wouldn’t want to eat anything covered in feces or urine either.

I can say for certain I never thought of putting manure on the trunk to deter critters. And pee too? It does make sense, I wouldn’t want to eat anything covered in feces or urine either.