I started welding as a new hobby just when covid was getting going in 2020. I didn't want to spend too much, so I ended up getting a SUNGOLDPOWER inverter welder. It was ~$200 on Amazon and could run on 120v and 240v. It had pretty solid reviews too, so I was convinced to give it a try.

https://www.amazon.ca/gp/product/B07T244BYC/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1

Fast forward to 2022 and here I am in a welding program on my way to get my CWB ticket for flat stick and flat MIG. I'm probably going to get myself a higher end TIG/stick welder too. How things change!

It just popped into my head a couple weeks ago that I had never run my little welder on 240v. So today I brought the wee gaffer to school and ran some tests. Instead of just trying it out, I decided to do a direct comparison to the welder I use at school: the Lincoln Idealarc 250 stick welder. It's a beast of a machine that runs with a transformer instead of an inverter. It's capable of running in AC and DC, and can go up to 300 amps.

Here are the competitors.

Weighing in at just 16lbs this $200 CAD welder is certainly the lighter of the bunch.

And coming in at 350lbs this beast of a welder is harder on your back (when moving) and your wallet at $5651 CAD.

And here is the testing station:

To test I cut two pieces of 1/4" flatbar at 6" in length. Then I ran a series of beads with both welders:

1/8" 6013 stringer @ 125A

5/32" 6013 stringer @ 140A

1/8" 7018 stringer @ 125A

5/32" 7024 stringer @ 200A

5/32" 6013 weave @ 160A

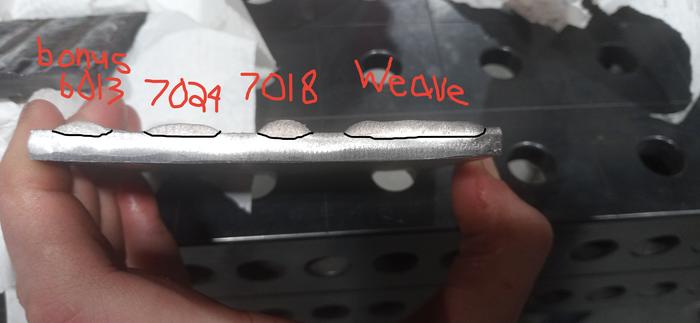

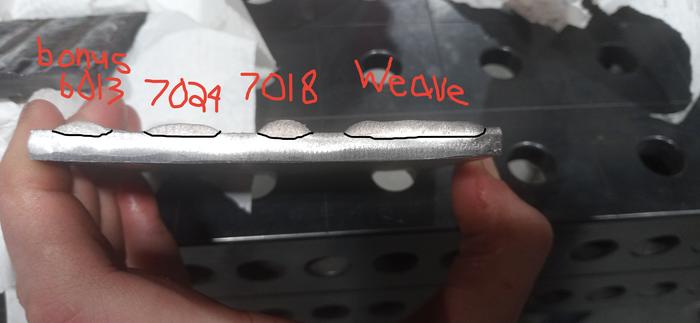

Here is the finished plate done by the cheapo welder.

And here is the Lincoln's work.

You may notice an extra bead on the bottom of the cheapo plate. That was a bonus 6013 5/32" bead I ran, because the first one I ran up top seemed cold. I wanted to make sure it wasn't just me.

The differences in power were apparent especially with the 6013 5/32" weave. The little welder kept the arc going, but the puddle did not get big enough to really fill the gap in completely. I found I was fighting it a little bit. A weave is basically a weld where you get a nice big puddle going and 'stitch' or 'weave' a big gap. If you do it correctly, it looks like you ran a string bead with a giant welding rod. This was no problem with the Lincoln at 160 amps, but with the Cheapo you can see my weave pattern. The arc stayed lit just fine, but the puddle was much smaller and thus it was harder to really fill the gap up.

Take a look at the up close of the Cheapo weave. I drew in the pattern lines that (ideally) you should not see in a weave.

And compare that to the Lincoln:

In addition, starting the arc on my welder was more challenging than with the Idealarc. That aside, my welder did a comparable job to the Idealarc. The arc was smooth, and only once did I struggle with it going out. It was with the 7018 1/8" rod. I originally was running a Bonarc brand rod, but the arc barely stayed alive. So I ground my weld down and restarted with a Lincoln Excalibur instead - it went just fine. The Idealarc had no issues with any of the rods, unsurprisingly.

Here is the start of the Cheapo 7018 run that did not go well. A little grinding brought it back to fresh steel and I restarted with a Lincoln rod instead.

In addition to the weaves and stringers with 6013 and 7018, I ran a stringer with a 5/32" 7024 rod. Those rods are just wild. They have iron powder in the flux, so they are great at laying a lot of metal down very quickly. I ran it at 200 amps, mostly because that's nice and warm for those rods and it maxed out the Cheapo. Both machines ran the rod just fine, but there is a noticeable difference in size. The Lincoln definitely burned more of the rod.

Here's a 1/8" 6013 rod beside a 5/32" 7024 rod. Notice how much flux the 7024 has!

Now how about penetration? Great looking welds are nice and all, but at the end of the day, the point of welding is to fuse metal together. One way to find out how much penetration you got is to cut and etch. So what I did was cut both plates in half after I was finished welding. Then I used a flap disc on a grinder to polish the cut edge to a smooth, shiny finish. After that I coated the edges with Krud Cutter, which contains phosphoric acid. I don't understand the chemistry at all, but doing this makes your weld metal a different shade from your base metal, so you can clearly see how far you actually melted into the metal. There was a difference in penetration - the Lincoln went deeper into the metal. However the difference (at least to my eye) is not dramatic.

Here is the Cheapo penetration. Just a note - I think I drew the penetraion line for the weave a little deeper than it actually went. If anything the Cheapo had slightly less penetration than the Lincoln.

And here is the Lincoln:

So what have we learned here? The Lincoln is definitely the better welder. It is more powerful and offers easier arc starting. However I am thoroughly impressed with the Cheapo. For just $200 CAD it performed extremely well. Another thing to note is that Cheapo will not run 6010 rods. There is something about the rod composition that just doesn't work. The Lincoln will run just about any rod that exists. If I were to do this again I would bring my 6011 rods from home to see how the two welders compare. 6011 is very deep penetrating. I just happened to forget them at home that day and we only have 6010 at school. In addition the Cheapo had issues running the Bonarc brand 7018 rod. Not sure why - but it seems these quirks seem to show up with the cheaper welders.

Just running this test convinced my two teachers that inverter welders are nothing to sneeze at. One wanted to try it on 120V, so I let him have at it. He was very impressed with what it could do. So for any of you folks thinking about getting into stick welding, do not let their dimiunitive size fool you: inverter welders pack a punch! Even at just $200 you can get some real solid welds.

11

11

1

1

1

1

1

1

2

2

2

2

1

1

2

2

2

2