2

2

Maybe Life is always like being on a trapeze or a tightrope at the circus...

5

5

Fish heads fish heads roly poly fish heads

4

4

Dan Fish wrote:I think if it's hard on splitters then it's a good thing you plan on renting! But to be honest I am sure the splitter will be fine.

Be careful out there. We don't have elm where I live but so far I haven't found a species of standing dead tree that isn't worth a little extra caution.

Maybe Life is always like being on a trapeze or a tightrope at the circus...

6

6

“It’s said war—war never changes. Men do, through the roads they walk. And this road—has reached its end.”

8

8

“The most important decision we make is whether we believe we live in a friendly or hostile universe.”― Albert Einstein

1

1

Jordan Holland wrote:Welcome to the club! You are correct that the grain is "twisted" in elm. Elm has interlocking grain, as it's called. Attempts to split it down the middle will test your patience. Driving a wedge will only amplify the frustration. You can, however, split slabs off the side of a round relatively easily. You can experiment with how far from the center you have to get to make it splittable. If the core piece is still too large, you might be able to split some more slabs off of it.

A hydraulic splitter will not split it really, but a sufficiently powerful one will tear its way through. Most wood will offer resistance at first and then come apart easily once it has popped apart. Not elm. It will have to be forced apart its entire length, and will leave the raggediest edges you have ever seen! It is truly impressive to see just how tough this wood can be. If the rounds are shorter than your chainsaw bar, you might consider ripping them instead, though if they are seasoned it may not be much easier. Green, it cuts well. It holds a lot of water.

I've been meaning to make a video of taking an axe and splitting a large round of oak and then placing a little 4"x4" round of elm on top and hitting it as hard as I can with the same axe just to show how tough the elm is, but haven't gotten around to it. It does make excellent firewood, though. It does not have the highest BTUs (which most people look at), but has a reputation for having some of the best-burning coals.

Maybe Life is always like being on a trapeze or a tightrope at the circus...

John Weiland wrote:The Red River Valley area that we are in is relatively species-poor when it comes to large hardwoods. For burning, probably 50-60% of what we use is elm (both American and Chinese) and the remainder is box elder or ash. Plenty of oak exists east of us outside of the valley, but I'd have to buy wood if I wanted some in the pile. I group my elm rounds after chainsawing into 3 groups--one piece knots, 'cold' splitters, and 'warm' splitters. After a while and getting to know the appearance that allows one to create those divisions, your summer and fall chainsawing will naturally cut to form these groups for the stacking. Once burning season starts, you can use small 2-4 " round branch material for running the stove as well as 'warm' split rounds.....those pieces that have straight enough grain to split 'as is'. Those that are a bit more resistant to splitting, I toss back into the stack for those days that follow nights where temps dipped into the minus 20s or minus 30sF. Swinging the maul when it's below 0F is not as awful as it sounds and the 'cold' splitters that wouldn't split in warmer temps seem to pop right open with the colder temps. The mid-winter days also are for burning the one-piece knots.....chunks so twisted nothing can split them, but they are cut during chainsawing to be used like a large lump of coal. Toss these in as the last log before bed if you want a slow burn through the night or early in the day if you want the same burn over several hours.

Side note that may be due to our high water table. Although *some* standing, dead elm is pretty dry at the time of harvest, I find that fallen trees sometimes are better seasoned. It's only conjecture, but even a dead tree has capillaries where the vessel elements once were.....those elements through which water once travelled upwards in the tree when it was still alive. Even when dead, with a high water table, it's still possible that water may wick up to some extent into the lower trunk, where one is drawn to cut due to the size of the rounds. These just take extra drying out before use in the stove and possibly should be split ASAP in order for faster drying before winter.

Maybe Life is always like being on a trapeze or a tightrope at the circus...

1

1

At my age, Happy Hour is a nap.

1

1

Where there is Liberty, there is Christ!

1

1

Brody Ekberg wrote:

So can you tell by looking at the pieces which ones will split ok warm vs cold, or do you have to take a whack at it?

“The most important decision we make is whether we believe we live in a friendly or hostile universe.”― Albert Einstein

John F Dean wrote:Taking note of your location, I lived for 4 years in northern MN. My experience was that the colder the temp is, the easier the wood splits.

Maybe Life is always like being on a trapeze or a tightrope at the circus...

Thomas Tipton wrote:I suffered through splitting a truckload of elm rounds with axe, maul, sledge hammer and wedges. Many of them proved nigh impossible. If I had to do it again, I'd save it all for bonfires. Harvest the branches and anything you don't have to split.

Maybe Life is always like being on a trapeze or a tightrope at the circus...

1

1

John Weiland wrote: Elm can be a pain, but with the heat produced and the volumes of tree fall due to Dutch Elm Disease, it's a no-brainer fuel source.

Maybe Life is always like being on a trapeze or a tightrope at the circus...

4

4

2

2

3

3

Determining the difference between Bockings 4 and 14 is done by consensus. It's like trying to identify the difference between twins.

"There are other spots on the web to get my fix proving someone is an idiot but no other place for what I get here." -- former permie Brice Moss, 2012.

3

3

Moderator, Treatment Free Beekeepers group on Facebook.

https://www.facebook.com/groups/treatmentfreebeekeepers/

1

1

Gray Henon wrote:Got a trunk load of elm early in my wood burning days. Was really surprised how much effort it took to split a 10” round with an 8lb maul. I finally beat it all into submission out of sheer determination. I’d have to think long and hard about some “free” elm! That said, I didn’t have a chainsaw at the time, now I do, and I am not against “ripping” stubborn logs down to size.

Maybe Life is always like being on a trapeze or a tightrope at the circus...

1

1

Phil Stevens wrote:I got a bunch of elm from my local arborist for free for this very reason...he hires casual help to do the splitting and doesn't want to subject the guy to health and safety issues. I tried splitting a few of the rings and gave up after knocking slabs off some of the edges. The good news is that there is some beautiful figuring in those gnarly pieces and a few are actually burls, so I try bandsawing them for turning or other craft type work.

Maybe Life is always like being on a trapeze or a tightrope at the circus...

1

1

Gary Numan wrote:I enjoy reading the forum at FirewoodHoardersClub.com . Now and again you can find an entertaining thread about the PITA that is elm. Plus at least one guy who maintains that he loves splitting it.

Maybe Life is always like being on a trapeze or a tightrope at the circus...

Michael Cox wrote:We processed an elm once for firewood. It was an absolute beast, and back breaking with an axe.

We ended up cutting shorter rounds to give ourselves more of chance.

Maybe Life is always like being on a trapeze or a tightrope at the circus...

2

2

Brody Ekberg wrote:

I think i might try splitting slabs off of the bigger rounds today to see if I can get them down to fit in my stove. Ive been Christmas shopping online and have enough built up rage from dealing with technology that smashing some frozen wood with a maul actually sounds fantastic right now. Too bad there arent some phones, laptops, tablets and computers in my wood pile for me to swing at too!

1

1

Brody Ekberg wrote:

Gary Numan wrote:I enjoy reading the forum at FirewoodHoardersClub.com . Now and again you can find an entertaining thread about the PITA that is elm. Plus at least one guy who maintains that he loves splitting it.

I think splitting it while raging mad would be great. And due to using technology lately, I’ve got some pent up rage to release!

I still wonder how elm splits with a hydraulic splitter though.

“The most important decision we make is whether we believe we live in a friendly or hostile universe.”― Albert Einstein

5

5

Brody Ekberg wrote:

Gray Henon wrote:Got a trunk load of elm early in my wood burning days. Was really surprised how much effort it took to split a 10” round with an 8lb maul. I finally beat it all into submission out of sheer determination. I’d have to think long and hard about some “free” elm! That said, I didn’t have a chainsaw at the time, now I do, and I am not against “ripping” stubborn logs down to size.

I haven’t ripped any logs but i would imagine it is difficult and inefficient. Although apparently so is splitting elm with a maul! I can fit a couple 8” rounds into our stove at a time and they burn quite a while but anything bigger than that will need some work. I would rent a splitter before I ripped them with my saw.

![Filename: 236234-578b5bbbd6707cce0016b729d6823d6a.jpg

Description: [Thumbnail for 236234-578b5bbbd6707cce0016b729d6823d6a.jpg]](/t/205616/a/196560/236234-578b5bbbd6707cce0016b729d6823d6a.jpg)

“It’s said war—war never changes. Men do, through the roads they walk. And this road—has reached its end.”

2

2

Brody Ekberg wrote:

Gray Henon wrote:Got a trunk load of elm early in my wood burning days. Was really surprised how much effort it took to split a 10” round with an 8lb maul. I finally beat it all into submission out of sheer determination. I’d have to think long and hard about some “free” elm! That said, I didn’t have a chainsaw at the time, now I do, and I am not against “ripping” stubborn logs down to size.

I haven’t ripped any logs but i would imagine it is difficult and inefficient. Although apparently so is splitting elm with a maul! I can fit a couple 8” rounds into our stove at a time and they burn quite a while but anything bigger than that will need some work. I would rent a splitter before I ripped them with my saw.

Where there is Liberty, there is Christ!

Jordan Holland wrote:

Brody Ekberg wrote:

Gray Henon wrote:Got a trunk load of elm early in my wood burning days. Was really surprised how much effort it took to split a 10” round with an 8lb maul. I finally beat it all into submission out of sheer determination. I’d have to think long and hard about some “free” elm! That said, I didn’t have a chainsaw at the time, now I do, and I am not against “ripping” stubborn logs down to size.

I haven’t ripped any logs but i would imagine it is difficult and inefficient. Although apparently so is splitting elm with a maul! I can fit a couple 8” rounds into our stove at a time and they burn quite a while but anything bigger than that will need some work. I would rent a splitter before I ripped them with my saw.

I've done it both ways, and for me it's much faster and easier to rip them than use a power splitter. I also won't hesitate to rip any crotch pieces and such from any species. As long as the bar is longer than the round is, ripping it is a piece of cake if the chain is sharp. It's not as easy if it's seasoned, but still easier than most splitters. Also, with ripping you don't have to manhandle the large rounds into position; you just rip them where they lay and carry away the small pieces. The ribbons of wood it produces is also the best tinder I've ever seen. I even saw a guy somewhere say that after he bought a Stihl 660, he quit splitting everything and just ripped it all because it was easier and faster.

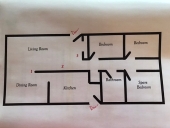

Here's a pic I just swiped from Hearth.com of someone splitting elm on a power splitter: (not always this bad, but like I said, it doesn't split but rather tears it apart.)

Maybe Life is always like being on a trapeze or a tightrope at the circus...

1

1

Thomas Tipton wrote:

Brody, when I first got it, I didn't know what it was. It was very wet at first and impossible to work with. My "more knowledgeable" neighbor tipped me off as to what species it was and what I'd be dealing with. I let it dry out over a year and went at it again in the fall. I got what I could off of it. The exercise was probably more valuable than the btu's the effort yielded. I found that any rounds that were free of branch intersections were productive, everything else was a means to punish myself for past transgressions. I recently had a very, very, large Chinese elm taken down on my property and didn't even bother with having them try to save any of it for me. Researching Elm as firewood will show that it is one of the least desirable forms of firewood for home heating.

Maybe Life is always like being on a trapeze or a tightrope at the circus...

2

2

John Weiland wrote: I've known several in upper management positions who "containerize" their frustrations and look forward to that wood pile that needs splitting by the end of the week. Perhaps, just as wood is ranked on btu's and growth rate, we could create a scale that ranks on splitting ease and the ability to relieve pent up tension.... :-)

2

2

Brody Ekberg wrote:......Its that bottom 1/3 that might not be worth the effort for me. But with it being dry and frozen I’m going to give a whack at it and see how it goes. If it sucks too badly I’ll try hydraulics. If thats a mess too then I just wont take the base of the trees home anymore!

“The most important decision we make is whether we believe we live in a friendly or hostile universe.”― Albert Einstein

John Weiland wrote:

I find the bottom 1/3 *generally* to be more free of knots and branches, even if some just seem gnarly the entire way up. For those larger diameter pieces in the lower 1/3, it may be worth it if the saw is sharp and the operator willing to cut those to more of a 12 to 14 inch maximum length for the purposes of easier splitting or fracturing. As you noted, be patient with drying....I've tried to rush too early on some and unseasoned elm will punish you. As a side note with the big pieces, I can just get too fatigued by the end of the summer and fall to get everything into small, choppable pieces. In these cases, I just have a covered pile of 6' - 8' long trunks or limbs under a tarp or overhand to stay dry. If it's a bad winter and I run out of chopped stuff early, I have these in reserve and usually don't mind chainsawing a bit in March and April to round out the burning season.

Maybe Life is always like being on a trapeze or a tightrope at the circus...

Where there is Liberty, there is Christ!

1

1

I just can’t picture a good way for me to rip these rounds without getting my saw in the dirt or without having unstable pieces of wood rolling around on me as I try to cut. Unless I make a cradle to set them in, that would be easy. But my saw has a 16” bar and that's the same length that I cut firewood. And this elm is all long dead and pretty dry.

Julie Reed wrote:

Ripping with a chainsaw is hard on the saw. If you only have a 16" bar, that's probably a small saw, so even worse. Ideally you want a 90+ cc saw, and also special ripping chain, which has different profile teeth. Once-in-awhile ripping is one thing, but if you plan to do a lot of it... now you're talking about chainsaw milling. You will burn up a small saw in a hurry.

My experience- I grew up where there was thousands of dead elm trees. Burns hot for sure. Splits hard, even with the biggest of hydraulic splitters. You really need a 30 ton rated unit or you'll waste time with half-split pieces stuck on the wedge, and the cylinder just straining but doing nothing. We also used what was called a Monster Maul (I think that was a registered trade name). Probably about 15-20 pounds overall, and it cannot get stuck in the wood due to the wide angle of the head. It's a workout! It also jars your entire body with every whack. Mother Earth News advertised them. The local logging supply sold them. Pic attached.

It's hard to turn down free wood (we are all so gullible!), so we burned a lot of elm. Anything smaller than 6" did not get split. Slabbing off the sides is definitely the technique to use (with any large pieces of any species), and frozen wood obviously splits easier since it can't 'absorb' the impact by the maul.

Our solution- After the first few cords of elm, we concluded that the time spent splitting was not efficient given the end result. Ripping was hard on the saws. Going with the 'anything smaller than 6" didn't get split' idea, we finally decided to just cut all the wood in 6" lengths. Depending on diameter, those pieces could be very easily split if needed, so our pile became a lot of 'half-moon' pieces. It wasn't great for stacking, and we ended up tossing most of it into the woodshed loosely on top of pallets. It was already dead standing, so drying wasn't a big concern. So, more chainsaw gas and more chain filing, but much less physical labor, much less time.

Needless to say, I don't miss Elm!

Maybe Life is always like being on a trapeze or a tightrope at the circus...

3

3

Hopefully my subaru outback can pull a 30 ton splitter. No idea how much those might weigh, but I could always borrow my neighbors truck if need be.

That monster maul looks like a beast! I wouldn’t mind trying one just to see how it goes, but that metal handle seems like it would be pretty brutal to work with.

It is certainly a workout but I actually need that.. I even asked my physical therapist friend if splitting wood is a good workout or a body destroyer and he said 100% great full body workout so long as proper form is used.

2

2

“The most important decision we make is whether we believe we live in a friendly or hostile universe.”― Albert Einstein

John Weiland wrote:Just chiming in here to say it's refreshing to hear other's experiences with elm. As noted earlier, we live in the heart of elm/dutch elm disease country and I've gotten very accustomed to sizing up elm pieces for splitting or burning whole. On a few occasions, strangers from strange lands (i.e., a few miles from here into more central Minnesota oak country....lol) delivered some straight red oak to me. I was bewitched by this strange, easy splitting, hot tempered soul....and knew that I could become spoiled quite easily if I took to ordering truckloads instead of dealing with the free wind-fall before me in dead elm. Splitting and burning that oak remains a fond memory, like an old girlfriend remembered briefly. The elm endures as the steadfast, if imperfect, keeper of the household flame.... :-)

Maybe Life is always like being on a trapeze or a tightrope at the circus...

|

We cannot change unless we survive, but we will not survive unless we change. Evolving tiny ad:

Rocket Mass Heater Jamboree And Updates

https://permies.com/t/170234/Rocket-Mass-Heater-Jamboree-Updates

|