God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Self-Proclaimed Renaissance Man and Gizmologist.

1

1

Satamax Antone wrote:

Lately, for prototyping, i use superwool 607 grabbed on eBay. And metal outside of the superwool. Just to hold it.

Henry Jabel wrote:

Satamax Antone wrote:

Lately, for prototyping, i use superwool 607 grabbed on eBay. And metal outside of the superwool. Just to hold it.

Have you tried this ceramic board super wool too?: Ebay superwool board link

Perhaps if it's more rigid you can minimise the amount of metal?

Satamax Antone wrote:To me real rocket is insulated to reach proper temperature and combustion.

How permies.com works

What is a Mother Tree ?

Bruce Woodford wrote:

Satamax Antone wrote:To me real rocket is insulated to reach proper temperature and combustion.

OK, what is proper temperature? Where in the core is it measured?

What is proper combustion? Must this measured by a Testo? So if someone's rocket has not been Testo Tested is not a Rocket?

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Austin Shackles : email anshackles"at"gmail.com.

Bruce Woodford wrote:

So you say a real rocket will develop flame path temps of 800-900C or 1472-1652 F (this is well above 900F or so where steel starts to glow red and will very quickly oxidize and spall.)

Now while my air-cooled core does not glow red, the flame path within it far exceeds 900F! I have melted aluminum (temps above 1220 F) 2 feet up in my heat riser in about 30 seconds from lighting the fire! Do you not think that by the time the system really gets heated up that that temp range just might go up another 200 -400 degrees F???

How permies.com works

What is a Mother Tree ?

Bruce Woodford wrote:Satamax,

Please understand, I am not seeking confrontation, just information so we can accurately address facts and come to proper conclusions.

So you say a real rocket will develop flame path temps of 800-900C or 1472-1652 F (this is well above 900F or so where steel starts to glow red and will very quickly oxidize and spall.)

Austin Shackles : email anshackles"at"gmail.com.

Austin Shackles wrote:Not actually found the references I want (yet) but I did find these 2 pages:

melting points of metals. Steel actually isn't "molten" at the temperatures you want to achieve, but it might well be hot enough that it's no longer structurally sound, because steel doesn't change from solid to liquid like ice changes to water - it becomes progressively softer and more malleable until it reaches a point where it flows and could be considered "molten". Steel will and can also oxidize, if there's any surplus oxygen around. For example, an Oxy-acetylene torch cuts steel by using a narrow jet of oxygen applied to oxidize bright red hot steel. However, in a stove, you'r fairly unlikely to have much surplus oxygen.

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

Peter Chauffeur wrote:Hi John.

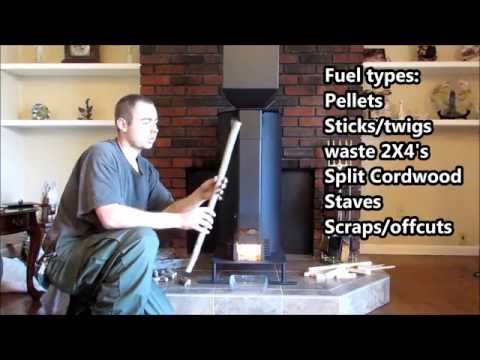

I recently posted my prototype Rocket Stove / Mini Thermal Mass Heater on this site. I ran it for 3 Years from fall to spring each year and posted a thread on its autopsy. I used standard thick walled square tube for the burner and 3 inch diameter muffler tube for the riser. Now 3 years of start and stops every day ( as I shut the pellet stove down each night} is a lot of cycles and the riser did manage to suffer fatigue and I think it was due to bell housing not being able to dissipate the heat quickly enough. I am currently building a Mark 2 version and I am recycling the burner assembly for two reasons: 1} The burner assembly works very well and 2} it will be a benchmark for when I actually have a little more time to make a second burn tube with a larger hopper and continue my experimentation with steam injection in the secondary air inlet. Check out my design, perhaps we can exchange ideas.

Peace Health Happiness

Peter Chauffeur

positively optimistic 🙂 https://www.youtube.com/@613Builds

God of procrastination https://www.youtube.com/watch?v=q1EoT9sedqY

positively optimistic 🙂 https://www.youtube.com/@613Builds

|

A day job? In an office? My worst nightmare! Comfort me tiny ad!

Freaky Cheap Heat - 2 hour movie - HD streaming

https://permies.com/wiki/238453/Freaky-Cheap-Heat-hour-movie

|