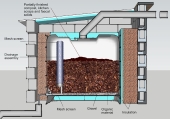

just finishing off my version of the wendy howard system , just bought a large bag of bark chippings and wait for delivery , also in ireland , so it was a good read about your system ,i have been a longtime convert but only recently built up something---part of my slow progression to off grid and taking responsibility for my output and lessen the pollution of groundwater. Did you have to insulate your IBC ---i have sourced the worms from an old dung heap out in the elements ---they dont seem to be effected by the colder ===although milder ----winters we have mostly ===,,and did your system recover and start up again ,cheers ,tony