Cellulose is a wonder material. I was just reading

this article on densified wood and it sure makes it seem like the revolution in green materials science should take over. Densified wood has tensile strengths higher than steel or titanium alloys! They discuss using it to build cars...wood sided cars are coming back :)

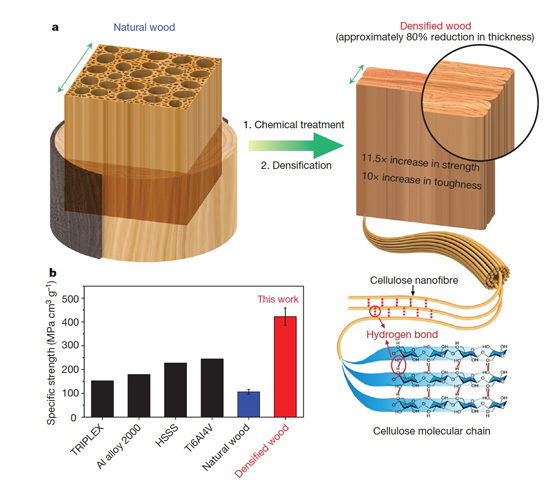

Figure 1 | Processing approach and mechanical performance of densified wood (Song et al., 2018).

(a) Schematic of the top-down two-step approach to transforming bulk natural wood directly into super-strong and tough densified wood. Step 1, chemical treatment to partially remove lignin/hemicellulose; step 2, mechanical hot-pressing at 100 °C, which leads to a reduction in thickness of about 80%. Most of the densified wood consists of well-aligned cellulose nanofibers, which greatly enhance hydrogen bond formation among neighboring nanofibers.

(b), Specific tensile strength of the resulting densified wood (422.2 Å} 36.3 MPa cm3 g−1, mean Å} standard deviation) is shown to be higher than those of typical metals (the Fe-Al-Mn-C alloy, TRIPLEX, and high specific strength steel, HSSS), and even of lightweight titanium alloy (Ti6Al4V).

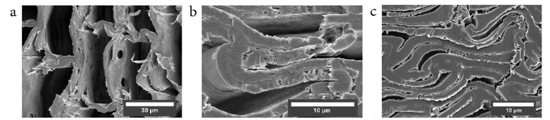

Figure 2. Delignification of native wood (a) results in a white cellulose scaffold (b). Densification of the delignified cellulose scaffold (c) results in a homogenous folding of the earlywood cells. (Frey et al., 2018)

Figure 2. Delignification of native wood (a) results in a white cellulose scaffold (b). Densification of the delignified cellulose scaffold (c) results in a homogenous folding of the earlywood cells. (Frey et al., 2018)

What would you build with this?