posted 13 years ago

Hey JC,

All the things you mention could be factors.

The gap you want between heat riser and barrel on a 6" system is about 1.5" to 2".

Insulation: If the 6"/8" heat riser is a double sleeve of pipe, that means you have only 1" vermiculite insulation. Vermiculite's not that good an insulator - we usually recommend about 4" thickness (6" ID to 14" XD), and mixing it with clay diminishes this insulation value much more than with perlite. All things considered, we usually use perlite and clay- 2" is sufficient - or rock-wool blanket insulation around a brick heat riser. Metal liners don't hold up over time, so the clay-insulation mixes need to be pretty high-grade to hold themselves in place when the metal burns out.

Insulation should not be affecting your problem with the bench heating up. Air leaks from a decaying metal heat riser, or conductivity of poor insulation, would cause combustion/smokeback problems (stagnation in the barrel). Whereas you report it's burning fine at the moment. But it might be worth adjusting if you do open it up again to change the gap.

If you do have poor insulation, but you haven't seen any combustion problems, it's also possible that extra draft from your exit chimney is masking those problems for now. Might lead to less effective self-regulation, cooler fires, and more sooting up. But also helps with cold starts.

Peter's right about the warming-in process. About a week to ten days of continuous firing usually does it for both drying and warming up. (It can get pretty steamy for a while in fact!) However, if this is a vacation cabin and your mass is literally frozen, you're going to have a longer process to first thaw and then evaporate that water. Both processes absorb an enormous amount of energy.

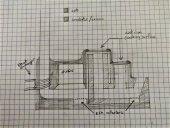

You don't say whether the heat-exchange pipes run back and forth, or if it's just a single run of pipe. That would be a lot of mass for a single run; surface temperatures might never exceed lukewarm. But with a double or greater number of runs, it might get warmer. If you want a hot, quick heat-up surface, consider more runs of pipe with less mass around them - maybe 4" or so from pipe to surface. On a 6" system you can do up to 3 180-degree turns, in that 7 foot space, if your chimney exits vertically near the barrel.

And finally - am I correctly understanding that you visited the heater for 3 days after leaving it alone for months? Is this a vacation cabin rather than a full-time residence?

Mass heaters are designed for routine use during extended heating seasons. The whole point of the mass is to maintain a steady temperature. When you are gone for a week or more, the temperature of your mass defaults to the ambient surrounding temperature. Just as it holds heat for days, it will take days to bring it back up to temperature.

In an occasional-use cabin, especially if it happens to be in some colder zone like a mountain retreat, this is going to be a pretty chilly setup. You may need passive solar heat collection, or a friendly neighbor coming over a day or two before your arrival, to get the mass up to temperature so that you don't have to completely re-heat it in the few days you're there. Or just fire it as long as you can, as soon as you can, each time that you visit.

Depending on the climate, an 8" system will generally produce a warmer bench than a 6" system - it can burn almost twice the amount of fuel in the same firing time.

Our bench, with three 8" runs in daily use, fluctuates between 70-90 F; it's never actually hot to the touch. (We are heating an 840 SF cabin with ambient outdoor temperatures in the teens to 30's F, where we remain throughout most of the winter. The rest of the cabin varies from about 60-65 in the pantry and bathroom (far corners), to around 80 in the living room near the heater.)

We find that the insulated, firebrick heat riser will hold some heat after the fire goes out. When we shut down the feed after the last coals have burned down (slide two bricks across, leaving only pinhole cracks), the warm air stagnates in the barrel, and the barrel may stay around 100-150F for hours.

If you have a lot of excess chimney draft (which might be suggested by the low amount of insulation in the heat riser yet failing to have smokeback problems), this excess chimney draft might be pulling cool air through the system after the warmth is gone, re-cooling the mass each night while you sleep.

Hope that helps.

Yours,

Erica W

1

1

1

1

1

1