May God Bless Each Task We Undertake. May Each Task Be a Blessing Unto God.

1

1

May God Bless Each Task We Undertake. May Each Task Be a Blessing Unto God.

May God Bless Each Task We Undertake. May Each Task Be a Blessing Unto God.

SilentTala wrote:

The greenhouse is going to be covered in greenhouse plastic on a wooden frame. What would I use to insulate the entry hole? I don't want to melt the greenhouse plastic.

I don't even know if a rocket stove is a good idea in a plastic greenhouse?

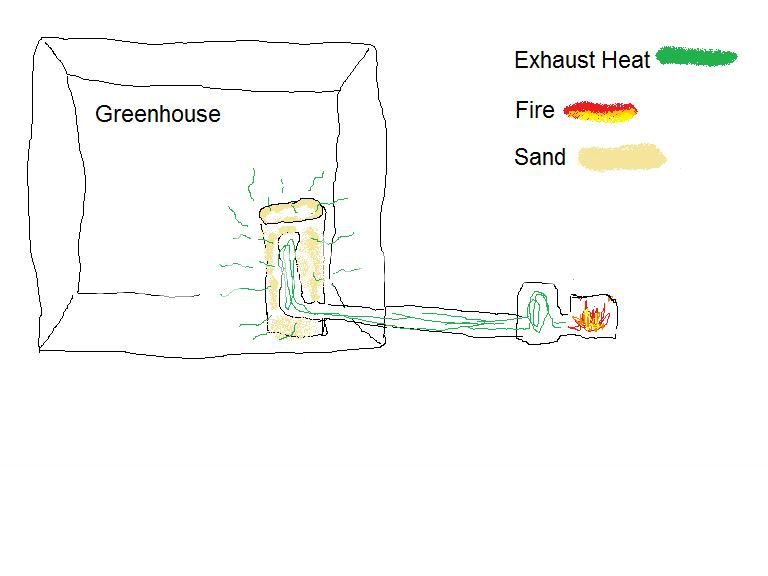

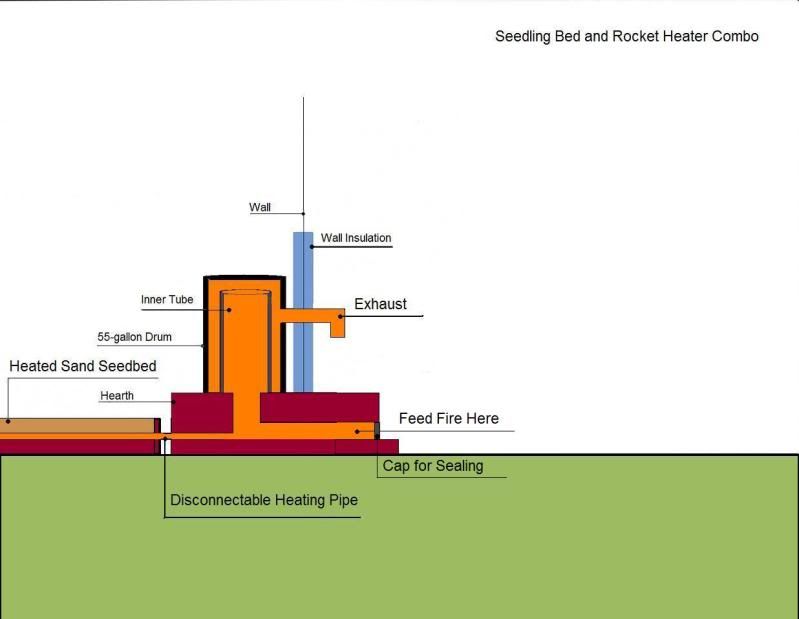

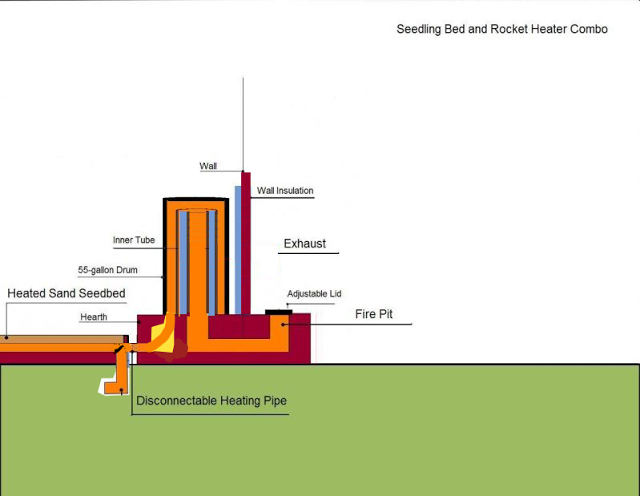

The large 55-gallon drum is filled with sand with a pipe going into it.

I would much rather put it closer to the GH--would mean less cost for pipe.

Awesome link! That is way too much pipe for my budget though. The greenhouse is 16'x16'.

If I did what you suggest and find a way to insulate the entry hole and wall, would this keep my greenhouse heated reliably through our winters? I'm in Tennessee so the winters aren't too bad.

This is all helping me come up with a good plan before fall.

This is all helping me come up with a good plan before fall.

May God Bless Each Task We Undertake. May Each Task Be a Blessing Unto God.

1

1

Cliff (Start a rEVOLution, grow a garden)

Projects, plans, resources - now on the Permies.com digital marketplace.

Try the Everything Combo as a reference guide.

Cliff (Start a rEVOLution, grow a garden)

careinke wrote:

Sorry about the face book link, I'm new to facebook and not sure why that did not work. If you look up Clifford Reinke on facebook I am pretty sure I am the only one. If not my profile picture is my garden and chicken coop.

Here is my latest youtube video.

http://www.youtube.com/watch?v=w5hNIvnZ51I

...hope this helps. I'll try to figure out how to post pics soon.

Projects, plans, resources - now on the Permies.com digital marketplace.

Try the Everything Combo as a reference guide.

May God Bless Each Task We Undertake. May Each Task Be a Blessing Unto God.

SilentTala wrote:

I thought if I had the main part outside, I could add wood to the pit without having to open the greenhouse door. Also, to prevent the whole smoke thing. My greenhouse will have animals in it--mammals, birds, fish, reptiles and pollinating insects. Oh, and a four-year old too! LOL

May God Bless Each Task We Undertake. May Each Task Be a Blessing Unto God.

SilentTala wrote:

Thanks for the responses guys! I'll read back through them after work today.This is all helping me come up with a good plan before fall.

What about one of these?

Projects, plans, resources - now on the Permies.com digital marketplace.

Try the Everything Combo as a reference guide.

Need more info?

Ernie and Erica

Wood burning stoves, Rocket Mass Heaters, DIY,

Stove plans, Boat plans, General permiculture information, Arts and crafts, Fire science, Find it at www.ernieanderica.info

Need more info?

Ernie and Erica

Wood burning stoves, Rocket Mass Heaters, DIY,

Stove plans, Boat plans, General permiculture information, Arts and crafts, Fire science, Find it at www.ernieanderica.info

1

1

Need more info?

Ernie and Erica

Wood burning stoves, Rocket Mass Heaters, DIY,

Stove plans, Boat plans, General permiculture information, Arts and crafts, Fire science, Find it at www.ernieanderica.info

G. Karl Marcus wrote:Ernie; The stove featured in the article found here: http://www.finehomebuilding.com/how-to-articles/kang-masonry-stove.aspx?ac=ts&ra=fp

was built by me in Missoula, Montana, in 1986. As you can see, the k'ang had a fairly large secondary burn chamber, about 40 feet of horizontal flue separated by firebrick walls and a cement block/clay liner, 8x12 chimney that stood in the corner of the room and was about 15 ft. in height. Flue runs were nine inches by approximately fifteen inches tall. Eventually, the firebox was fitted with an airtight steel door. As reported above, the stove burned vigorously, producing little smoke and no creosote. Primary and secondary pre-heated air was supplied through the door arrangement. Adding the door made the stove burn hotter and cleaner, as it offered control over excess air rushing through the system, and it allowed for some pre-heating of combustion air.

Cleanliness was never a problem, and it ate like a bird. One problem that did arise was perplexing. After a string of bad-air days, when the stove was cold, closing the door on a vigorously burning fire caused asphyxiation, and smoke problems. After repeated attempts, I finally reasoned that the bricks inside the stove, (probably 400 or so), were so cold they were absorbing all the heat from the flue gas before it got to the chimney. If the flue gas didn't rise up the chimney, fresh air would not be pulled in through the door frame. So, to solve the problem, I began burning the first fire after cold snaps with the door open. Problem solved.

Clean-out door at chimney-base offers a simple way to remedy any back-draft problems. If the stove is cold, a small wad of newspaper, or a weed burner, will easily and quickly reverse the flow. Typically what came up the chimney was clean, moist exhaust cool enough to put your face in, and a little fly ash.

G. Karl Marcus wrote:I'm not entirely clear what purpose the heat riser serves. If no immediate heat is needed, why not just channel the flue gasses horizontally, from firebox/expansion chamber, through stove baffles/mass storage system for as long as it takes to extract the heat, and then vent out a chimney?

Draft can always be established at the firebox by inducing draft with a small amount of heat, through clean-out access, at the base of the chimney.

Projects, plans, resources - now on the Permies.com digital marketplace.

Try the Everything Combo as a reference guide.

Projects, plans, resources - now on the Permies.com digital marketplace.

Try the Everything Combo as a reference guide.

G. Karl Marcus wrote:Ernie; The stove featured in the article found here: http://www.finehomebuilding.com/how-to-articles/kang-masonry-stove.aspx?ac=ts&ra=fp

was built by me in Missoula, Montana, in 1986. As you can see, the k'ang had a fairly large secondary burn chamber, about 40 feet of horizontal flue separated by firebrick walls and a cement block/clay liner, 8x12 chimney that stood in the corner of the room and was about 15 ft. in height. Flue runs were nine inches by approximately fifteen inches tall. Eventually, the firebox was fitted with an airtight steel door. As reported above, the stove burned vigorously, producing little smoke and no creosote. Primary and secondary pre-heated air was supplied through the door arrangement. Adding the door made the stove burn hotter and cleaner, as it offered control over excess air rushing through the system, and it allowed for some pre-heating of combustion air.

Cleanliness was never a problem, and it ate like a bird. One problem that did arise was perplexing. After a string of bad-air days, when the stove was cold, closing the door on a vigorously burning fire caused asphyxiation, and smoke problems. After repeated attempts, I finally reasoned that the bricks inside the stove, (probably 400 or so), were so cold they were absorbing all the heat from the flue gas before it got to the chimney. If the flue gas didn't rise up the chimney, fresh air would not be pulled in through the door frame. So, to solve the problem, I began burning the first fire after cold snaps with the door open. Problem solved.

Clean-out door at chimney-base offers a simple way to remedy any back-draft problems. If the stove is cold, a small wad of newspaper, or a weed burner, will easily and quickly reverse the flow. Typically what came up the chimney was clean, moist exhaust cool enough to put your face in, and a little fly ash.

Projects, plans, resources - now on the Permies.com digital marketplace.

Try the Everything Combo as a reference guide.

regards, Peter

)

)

Frank De Block-Burij wrote:I will replace the rockwool insulation with the recommended perlite or vermiculite apparently these can be bonded with sodium silicate (liquid glass) so maybe I can make my own boards

Frank De Block-Burij wrote:next there is the question of downer temperature: I seem to have seen other designs where the downer was insulated

regards, Peter

Peter Berg wrote:

Frank De Block-Burij wrote:I will replace the rockwool insulation with the recommended perlite or vermiculite apparently these can be bonded with sodium silicate (liquid glass) so maybe I can make my own boards

When you use the insulation as a loose dry fill, vermiculite is OK. When you intend to use clay slip or water glass, take perlite. This won't take up as much liquid as vermiculite. Reducing the trouble of getting rid of all that moist.

Frank De Block-Burij wrote:next there is the question of downer temperature: I seem to have seen other designs where the downer was insulated

Could be, but it's utterly wrong. Mind you, a lot of people are very happy when their stove is burning, at all.

Peter Berg wrote:

Frank De Block-Burij wrote:Your concept of the draft generator is a bit too complex. Try to see it as a thermosyphon system, much like old central heating installations without a pump and wide pipes. When one side is heated, the other side will come down. Hydrodynamics and aerodynamics do share common laws, it's largely just a different medium.

I would have thought my setup to be extremely simple, so please explain

Peter Berg wrote:

Frank De Block-Burij wrote:The sketch do show a 4x4 inch system, a bit too cramped for a stove that need to heat lots of water. Go for a 6" square instead, the riser etc could be the same length as you've drawn.

100 x 100 mm is what I happen to have in stock

besides, my temporary greenhouse will be small

and I am breeding burbot, a cold water species

so I only need to heat up the water to max 18°C or even much less in winter

Frank

| I agree. Here's the link: http://stoves2.com |