He's been a furniture maker, mold maker, composites specialist, quality inspector, master of boats. Roughly during the last 30 years he's been meddling with castable refractories and mass heaters. Built a dozen in different guises but never got it as far as to do it professionaly. He loves to try out new ideas, tested those by using a gas analizer.

He's been a furniture maker, mold maker, composites specialist, quality inspector, master of boats. Roughly during the last 30 years he's been meddling with castable refractories and mass heaters. Built a dozen in different guises but never got it as far as to do it professionaly. He loves to try out new ideas, tested those by using a gas analizer.

sara ventura wrote:-I was under the impression that concrete should be avoided on areas of highest temperatures, but here the pavers are right into the path of the gases exiting the core. Will this affect its longevity?

So your question was already answered, please read carefully.Since the core spews the hottest gases forward instead of upward, only a limited number of firebricks are needed directly above the firebox to protect it.

sara ventura wrote:-Have you calculated the minimum area around the core to ensure optimal gas flow?

sara ventura wrote:Do you think this design would allow down scaling? It's great for a workshop, but in my experience around here, space in workshops is always scarce.

sara ventura wrote:In Catalan architecture vaults are a thing, so I'm used to thinking that it's a shape that offers long time durability. But it's true Gaudi did never build masonry stoves, it makes sense that with high temps and expansion we're talking of a totally different game.

sara ventura wrote:Two first questions:

-Why is there a second door on top of the firebox on both designs?

sara ventura wrote:-In this design, the top of the bell and front wall are both lined with IBF to protect from direct heat, right?

sara ventura wrote:The other is about the possibility to finish the top of the bell with an arch instead of a flat roof. Leaving aside the technical difficulty of making a vault, would this construction offer advantages on long term durability and performance?

sara ventura wrote:-With the ISA I gain from shortening the bench, I could make the bell a bit higher. That would allow me to rise the core a bit further from the floor, not as much as to align with the ceiling of the bench, but closer.

sara ventura wrote:- Having a higher bell, I want to keep it as slim as possible. In order to do that, would it be possible to leave part of the core outside the bell? How does it work, construction wise? Is there any thread around here where this has been done?

sara ventura wrote:-And the last twist in design would be to forget about the cob render and clad the whole build once finished with glazed tiles. The house is poor in natural light and I have to finish the build in light colors. Would refractory mortar be necessary for bonding? This way I could have a render 5cm thinner than with the cob.

What are the contraindications with tiling, besides cracking?

sara ventura wrote:I want to start the fire on the days that inside the house is colder than outdoors.

sara ventura wrote:The floor of the core aligned with the top of the bench? So the temp of the core doesn't mess with the cool gases going down and find the exit, yes?

sara ventura wrote:But that will rise my top of the bell too, thus increasing my ISA again, no? 1m ISA would be a square bench of 50 cm square right?

sara ventura wrote:I'm having trouble imagining any other proportions that would work as a relatively comfortable seat for one person/dog.

sara ventura wrote:Actually for the core, today my father suggested the possibility to do tongue and groove construction. Is there a reason I haven't seen any so far in the forum, other than the obvious extra work of carving the bricks? We have a wet saw and an skilled brick layer here.

sara ventura wrote:The firebrick we'll be using for the riser will be AL 79-82% 1550ºC, with wire and a band of superwool for movement allowance and protection I'll be good to go?

sara ventura wrote:About that, we've opened a can of worms with my dad, will be making new sketches next week with some (probably) crazy ideas, you'all'll let me know!

sara ventura wrote:And to recapitulate, which are the highest temps expected at this points:

- Inside Firebox -

-Inside Riser -

-Inside Top bell -

-Inside Top Bench -

-Exit pipe -

- Optimal fumes temp at exit? -

sara ventura wrote:I was hoping to be able to have a hot bench next to the bell. Making some twitches to my current design I'm around 4.7 ISA.

I've read somewhere that by adding a bypass you can increase the ISA, how much are we talking about?

Is it feasible to have a small operating bench like the picture I attach below?

sara ventura wrote:I'm almost certain it's an IA picture, but it's the one I've found that looks closer to what I have in mind for my build (Minus the oven). In case this was possible, would all the face next to the bell be all open wide inside to allow the gases to flow freely?

sara ventura wrote:The exit pipe from the stove is currently 2cm and 15cm from the corner, so I have to move it anyway. If it's centered at the back of the bell, gases can flow from 3 diferent directions?

sara ventura wrote:Left, right and from under the core, is that correct?

sara ventura wrote:And the section of the pipe can be parallel to the floor?

sara ventura wrote:Being at 15 cm from the floor, is it convenient to rise the core a bit more than that to not have them both at the same level?

sara ventura wrote:I was planning to buy double wall insulated pipe for the masonry chimney to avoid condensation, which has always been an issue as it can be seen in the pictures of my corner. Can this same pipe be used inside the bell? and the section inside the house be simple wall?

sara ventura wrote:

It escapes me what you mean with wires to reinforce the heater core?

Sorry, I got lost in translation, I meant rods. As seen in the pictures of the Thomas Rubino's new build, I meant the internal frame that braces the core, and the wires to reinforce the riser.

sara ventura wrote:Then, probably just coating the wires from the riser that face the highest temps, and the rest of the metal inside the bell will be protected by the wood tar coating?

sara ventura wrote:If I go with the double wall tube, will this be protected enough? or giving a layer of Vitcas on the upper part won't hurt?

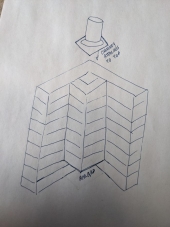

sara ventura wrote:My idea to crown the bell was to make double-skin only the last row and the top, as in the sketch below*. Should this apply to all the FB rows?

Even with cob finish instead of double skin bell?

sara ventura wrote:First questions raised by these drawings:

-Can the depth of the portal be 6.4cm? And the height of the riser 105cm instead of 108? 6.4 is the width of my firebricks.

sara ventura wrote:-Between the back of the firebox and the back wall of the stove I have left 21cm( x 61cm width). Is that enough?

sara ventura wrote:-Would it make sense to draw the riser on the left, place the exit pipe on the right corner and have a much shorter lever for the bypass?

sara ventura wrote:-Is 3 or 2 cm space enough to leave between the pipe and the internal walls? The exit pipe will have an angle as it is because of the thickness of the wall of the stove, so I may well place it wherever I want.

sara ventura wrote:-If I rise the core with a metal structure, would a vitcas paint coating 1750º/3180º or similar be ok to protect it and the wires to reinforce the riser and core?

Leonardo Bevilacqua wrote:I have a question though. I was examining your sketchup model of the door. In your model you built the airframe with a 60x60x3 mm square pipe, which has an internal section of 54x54mm which is 2916 mm2. If I follow the instruction on the page you sent, this section should be 15% of the chimney pipe section. The chimney pipe section for a 150mm system is 17671,5 mm2, and it's 15% would be 2650mm2, not 2916 mm2. I don't understand why measurements don't match. What am I getting wrong? This is only one example, but also the main slot opening doesn't match the requirements. Am I calculating something wrong? Or, should I just use your model, scale it up 1.2 times to match my 180mm system, and copy your measurements?