8

8

5

5

6

6

6

6

regards, Peter

4

4

5

5

Cerbu Ulea wrote:yes , I have installed skp 2021, send it if you can, also the layers . the dimensions you provided there, i will copy them here , very easy to adjust now , you also said I can go away with a bigger firebox length, as my wood is cut longish , at about 50 cm tops. what I still don't know is the exit port , ok 23 by 11.4 , and another eleven.5 to the riser roof?

regards, Peter

4

4

5

5

Cerbu Ulea wrote:understood now ,I can cut custom bricks from splits for the upper riser , I wait for the files. About the roofs , 4 plates of 360 x 160 , and two for the riser will do? some I already have , the rest can be bought , their thickness is 25 mm, https://www.utilul.ro/constructii/produse-zidarie/caramida-refractara/caramida-refractara-samota-brick-490-360x160x25-mm-p25490/

regards, Peter

2

2

6

6

Cerbu Ulea wrote:TY, i'll try my best , superwool on the outside of the core it's of any help?

regards, Peter

5

5

3

3

5

5

Cerbu Ulea wrote:I removed the old core and the under substrate , what should I fill it with to get to the floor level?

regards, Peter

4

4

6

6

Cerbu Ulea wrote:to elevate the core two bricks high , about 13 cm ,on an old cast iron cooking plate with 10 cm rock wool / or all 13 cm of air would do? it will remain space behind the bell even for a 100 120 mm bypass if it's a must , which I can remove when it is dry and warm

regards, Peter

8

8

4

4

5

5

Cerbu Ulea wrote:this is a way I start the bell after one week drying of the substrate, about 2.3 meters, 25 square foot ISU. Please help me calculate the ISU of the next bel, a vertical wall of terra cotta in two rooms, an external area of 1.5 square meters each room

regards, Peter

3

3

4

4

Cerbu Ulea wrote:there is a second hole , square ,aprox 110 mm wide , it can be seen covered with a cloth in the previous picture, they both enter to the wall, the round one has 170-180 mm in diameter, is that enough? wall's depth it's about 23 cm, the exterior is 1,5 m 2 , the interior is something like 1.2 max ; from the dimensions you gave me 159 would be the CSA, I cannot make the bell smaller for this core , but if there is too much ISA it counts if the roof is insulated ?

regards, Peter

4

4

5

5

regards, Peter

2

2

4

4

regards, Peter

4

4

6

6

Cerbu Ulea wrote:thank you, now simulation for the bell's wall

https://www.youtube.com/shorts/QELmcZtOnfI 90/90/90 cm give or take , too much isu?

regards, Peter

7

7

4

4

3

3

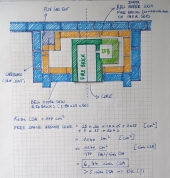

Cerbu Ulea wrote:i made a new simulation considering what you said, the smallest bell that can be done in order to allow room to breathe for the 160 mm dragon(more than five times csa ) and some stratification is 60/70 /65 cm with thickly insulated roof , it leads to 1.7 m2 ISA if only 4 walls are active?

regards, Peter

4

4

2

2

5

5

John Daley Bendigo, Australia The Enemy of progress is the hope of a perfect plan

Benefits of rainfall collection https://permies.com/t/88043/benefits-rainfall-collection

GOOD DEBT/ BAD DEBT https://permies.com/t/179218/mortgages-good-debt-bad-debt

4

4

4

4

regards, Peter

4

4

4

4

Cerbu Ulea wrote:yes, excellent solution, i can remove the round teracota cork and carefully drill a hole in it to operate the plate from the outside with a simple steel cable , today i made the triangular pieces of fire brick for the floor ; next on the list while the substrate is drying is the airframe , 6/4 cm is ok?

regards, Peter

5

5

4

4

Cerbu Ulea wrote:A flying threshold it's ok? I mean a 2-3 centimeters high bar of thin fire brick just under the front of the roof , So when the door is open the roof does not open directly to the room, I had it in previous build and reduces smells when refueling

regards, Peter

| I agree. Here's the link: http://stoves2.com |