9

9

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

7

7

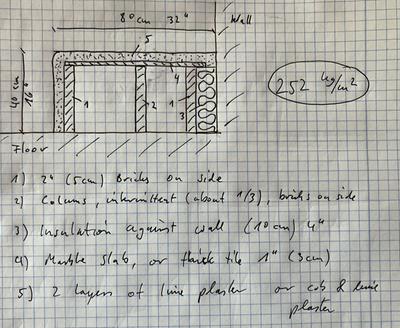

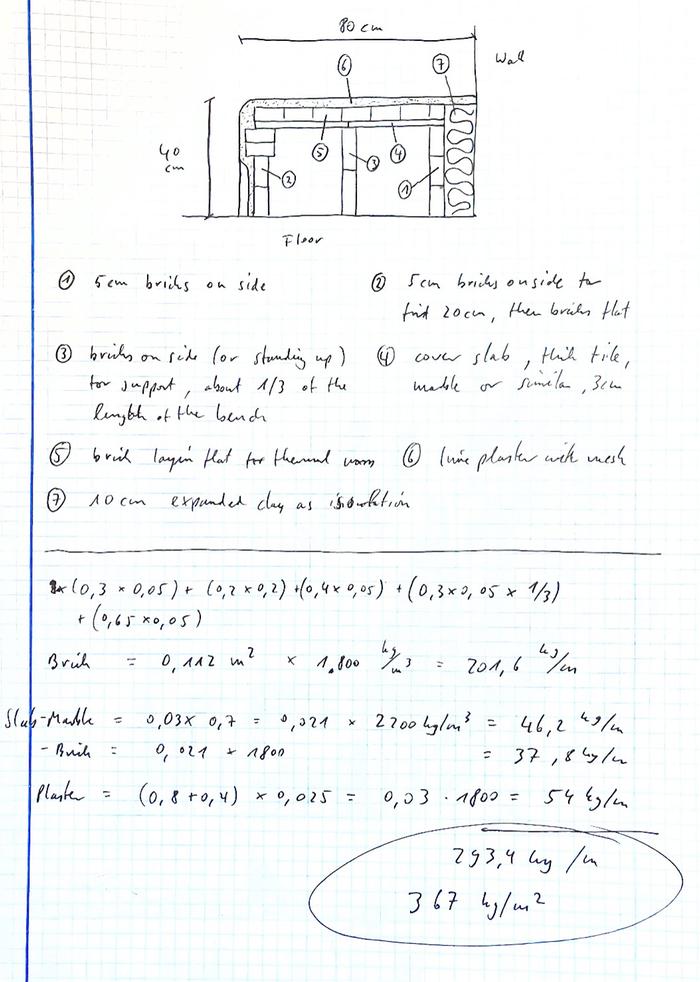

Benjamin Dinkel wrote:The bench would then need to be covered by some kind of slab that could span almost 30". I calculated with a thickness of maximum 3,5" including mortar and plaster to stay within the weight limit.

How permies.com works

What is a Mother Tree ?

7

7

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

7

7

Benjamin Dinkel wrote:

I can probably find some pre made concrete elements that fit my needs. Are concrete slabs an option?

Are there other good options that I'm not seeing?

Can metal profiles and heavy tiles be used too?

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

6

6

6

6

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

6

6

6

6

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

7

7

7

7

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

8

8

![Filename: HeatingBenchColumns.jpg

Description: [Thumbnail for HeatingBenchColumns.jpg]](/t/281004/a/269066/HeatingBenchColumns.jpg)

6

6

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

6

6

7

7

7

7

7

7

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

6

6

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

9

9

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

7

7

![Filename: 20241015_125214.jpg

Description: [Thumbnail for 20241015_125214.jpg]](/t/281004/a/271115/20241015_125214.jpg)

![Filename: 20241015_125219.jpg

Description: [Thumbnail for 20241015_125219.jpg]](/t/281004/a/271116/20241015_125219.jpg)

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

6

6

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

8

8

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

10

10

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

10

10

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

7

7

regards, Peter

9

9

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

8

8

![Filename: 8CB5AF58-A980-4413-BED8-3F53739BB4DF.jpeg

Description: [Thumbnail for 8CB5AF58-A980-4413-BED8-3F53739BB4DF.jpeg]](/t/281004/a/278043/8CB5AF58-A980-4413-BED8-3F53739BB4DF.jpeg)

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

5

5

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

11

11

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

6

6

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

6

6

Benjamin Dinkel wrote:As of yesterday the first Rocket Mass Heater designed and built by me is functional!

I’m very pleased with it. Jumped right to life despite being cold and wet.

The finishing plaster will be installed today and tomorrow.

I’ll update this thread with a documentation of the building process once I’m home and with a working PC.

Become extra-civilized!

10

10

)

)

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

7

7

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

5

5

Become extra-civilized!

7

7

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

9

9

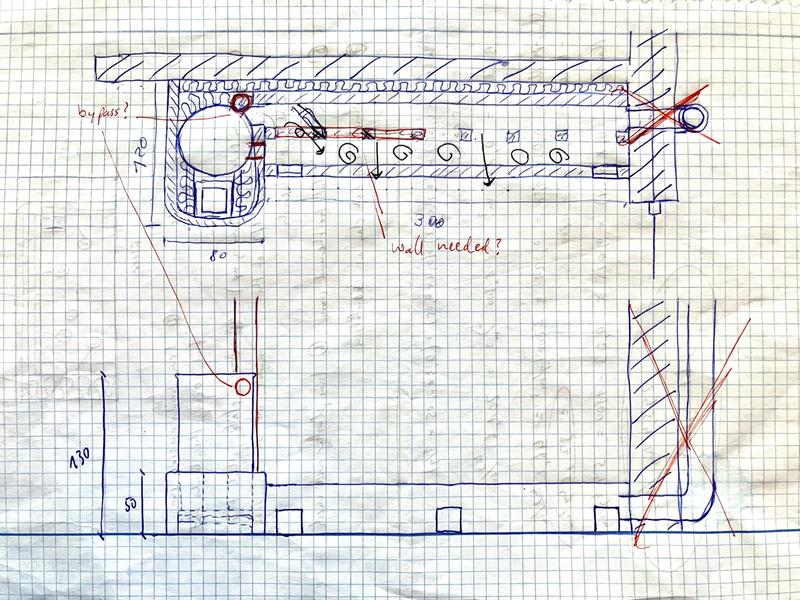

Coydon Wallham wrote:

Is the bypass not connected yet?

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

|

This parrot is no more. It has ceased to be. Now it's a tiny ad:

permaculture bootcamp - gardening gardeners; grow the food you eat and build your own home

https://permies.com/wiki/bootcamp

|