12

12

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

10

10

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

8

8

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

4

4

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

5

5

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

5

5

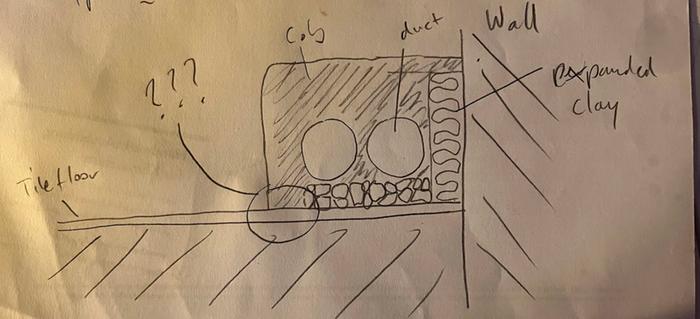

Benjamin Dinkel wrote:Has anyone some insight on this?

The insulation under the core will be 10cm of expanded clay, bound with clay slip. Expanded clay is the easiest o come by here. I was planning on building a border of cob, then pouring 10cm of the expanded clay and using that as the level board to build the first flat layer of fire brick.

And there I have a question: Will the cob attach to the tile floor or do you think I should put some screws or something into the floor to give it something to attach to?

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

9

9

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

6

6

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

10

10

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

4

4

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

6

6

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

5

5

6

6

3

3

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

3

3

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

5

5

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

6

6

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

4

4

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

4

4

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

6

6

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works

4

4

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

Proudly presenting RocketMassHeaters.com

A good starting point to all RMH research

How Permies.com works