To quote the person you want to address, just click the "quote" button. This will bring up a reply window with everything (words, links, pictures etc) in that post.

If you only want a part of the information, just delete what is not wanted, just be sure to keep the computer code "[quote /quote]" there. Use the "preview" button to verify how your post will look before submitting.

Peter talks about where to introduce secondary air on his site using his floor channel: "The air flow is optimized in such a way that the top half of the port receives the majority of the secondary air stream."

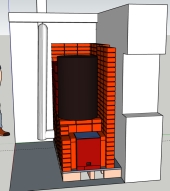

He also gives a sketchup link here:

floor channel sketchup file

You can use the online sketchup program at sketchup.com if you don't have it installed on your computer. A very useful tool.

From memory, distance from the port to the end of the floor channel is roughly 1.5"

You certainly don't have to bring it down to the floor, but for the reasons I mentioned earlier, it would be beneficial.

As a rocket scientist, every spot you put your thermometer can give you useful information. I don't know what yours is rated to, but assume its not high enough to give any burn chamber temps.

Helpful spots to know temps are if you are close to a combustible wall, or what the bench temp is under a blanket after sitting overnight at a glance, whether more mass could be added to increase your thermal battery heat time...etc.

Getting to know what your average exhaust temps are can be helpful in determining efficiencies. A candy thermometer inserted somewhere at head level in the vertical stack is a good place to put one.

A 10" OD which will give you 2.5" riser thickness should do nicely for your perlite/clay riser. It will definitely be much better than any high mass riser.

2

2

3

3

1

1

1

1

1

1

1

1