So there's a project in PEP for making a "kindling cracker." The thing is, I collect axes. I like axes. Why would I want a kindling cracker which removes my favorite tool from the equation? I thought about it, and after some thought had an idea you may have figured out if you read the title. I also make wood shakes (shingles). Traditionally one uses a froe for this task. But a froe is not perfect. It works by driving a blade with a handle mounted at a 90 degree angle into a block of wood, then twisting the handle to lever the two halves apart. Then repeat until they are about half an inch thick. This works fine if the wood is perfect. If not, the pieces do not want to rive cleanly, and one wants to tear apart and is ruined. When the wood is like this, I have noticed it can be prevented from tearing out by not levering the froe, and instead driving it through. But this is not optimal. It is very hard on the hands, and on the wooden mallet used to drive it. So I thought a kindling cracker with a very long blade could serve this purpose quite well, and make good shingles from less than ideal wood. And crack kindling, if you're into that kind of thing.

First thing is to decide from what to make it. My father brought these things home from his workplace years ago. I believe they were gates used to close off some kind of ducts that they decided not to use. Cool.

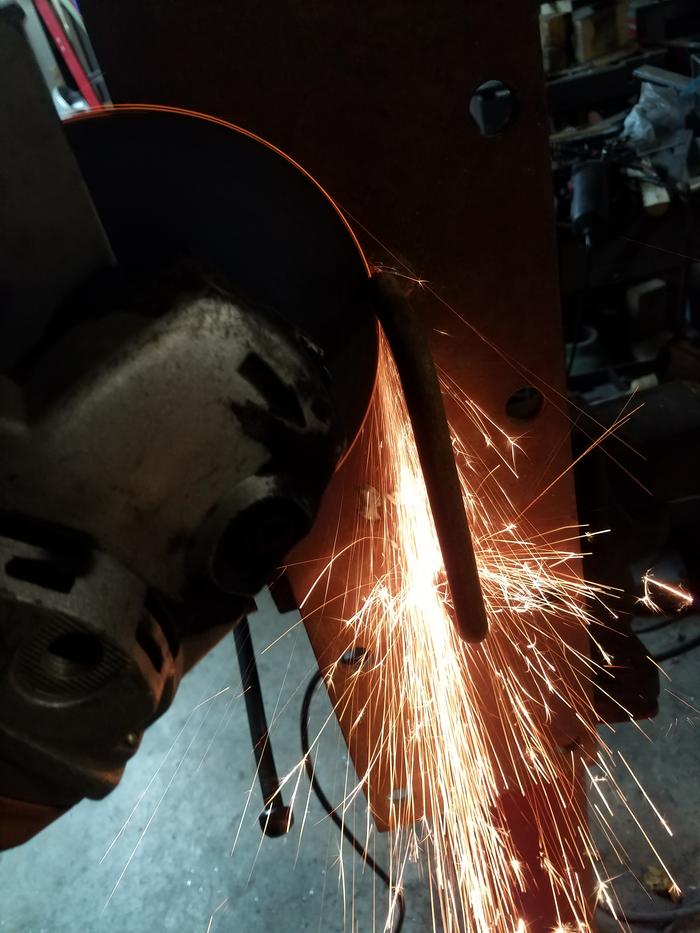

First the handle needs to go. A la fireworks!

Handle gone and base ground smooth. Better save that handle, I'll need it someday.

I want the cutting edge to be durable, and the plate is just mild steel. So I broke out the hardfacing rods and laid a coupla beads.

So here's where I get ticked off. I took many excellent pictures to accurately document this for everyone, and my phone decided to just pretend to take about half of them. Hmph! I had pictures of the edge being ground, some nice pictures of the rebar being bent into shape using the vise, some really awesome pictures of the rebar still glowing after being welded...but alas...evaporated into the ether... We pick up at the completion of THE KRAKEN! I think that's what I'll call it. I believe I currently hold the record for the largest kindling cracker on Permies! And yes, size does matter. 8 inches? Puuuleeeease!

Missing the pic of a full huge stick of firewood in its gaping maw, here we pick back up mid split. It's doing quite well. The narrow blade doesn't splay the halves apart, and the problems with one side tearing out are gone.

SHINGLES!

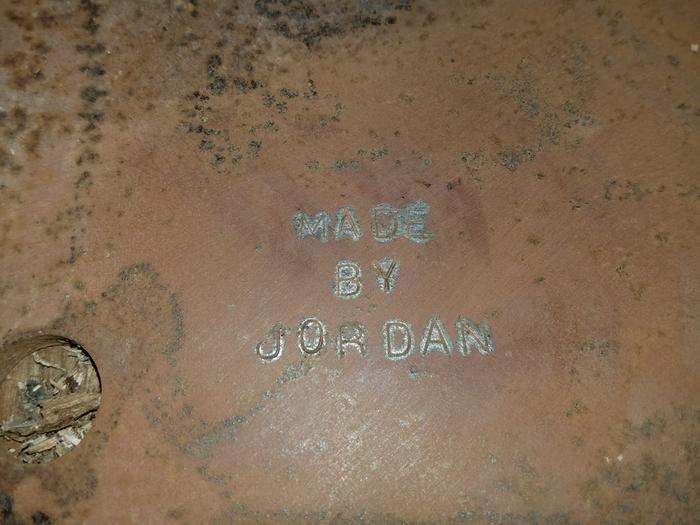

And so the world will know who made the biggest kindling cracker in all of Permieland...

I would have preferred to weld my name into it, or plasma cut it, but the instructions said "stamp," so I guess that works too.

Takeaways: It is a viable shingle-making maching. If I had to do it again, I would make sure the camera actually saves pictures. I also think I would forego the ring. Instead, I would make a single post on one edge of the blade with a 90 degree "V" to hold the wood upright, because the wood block can only be rested on one side or the other anyway. This would leave one side open for easier access for loading, and to remove a piece if it were to get stuck on a knot or something.

p.s. If you want an interesting brand, I can highly recommend a hot piece of rebar.