I missed the note about the vault structure.

There is a recent comment elsewhere about it and I included some notes.

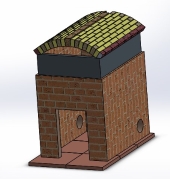

The walls do not need to be massive, the vault is shaped so only vertical loads are on the walls.

Earth structures, vaults design

basic-technical-rules

The load-bearing walls which support the vault are built of successive courses of large bricks and have a minimum thickness of 60 cm.

The courses are made up, in their width, of bricks laid alternatively lengthwise and width-wise, bound with earth mortar.

Joints between bricks must alternate from one course to the next to avoid any possibility of joints lying one above the other.

Various openings are made in load-bearing walls for doors and windows, and also for alcoves and cupboards to give extra storage space and to reduce the quantity of bricks and mortar

needed.

The gable walls are built with large bricks (35 - 40 cm long) which define the thickness of the wall. They must be built with a very slight inwards incline (of about 1 cm per metre of height). These openings are completed with lintels in the form of arches, formed over a barrel or an assembly of loose bricks.

The arches are made with small mud bricks and closed (in the case of alcoves or cupboards) by a 20 cm thick partition. The arches must be built before the start of the vault construction, and must follow the predicted slope of the vault.

The vaults are constructed without formwork or shuttering! They are built up with small (24cm x 12cm x 4cm ) mud bricks made from good quality earth, such as that used for granaries.

These bricks are placed course after course against the gable walls to form a vault which is basically semi-circular, except for the final segment at the stop of the vault, which is slightly ogival, forming a strong catenary shape.

Once the vault is completed, the masons build 'buttresses' by raising the load-bearing walls by 8- 10 courses of large bricks, and filling the void created on the flanks of the vault with earth

mortar and broken bricks. This 'loading' of the vault must be executed with care, especially if a flat roof terrace or another storey is to be added on top.

The height of the 'buttresses' can vary according to the client's wishes, but must reach at least 2/3 of the height of the vault. The best solution is to raise them to the

height of the vault, thus forming a more or less flat roof terrace, because the more the loading on the vault, the stronger it is, and the flatter the roof, the lesser will be the effects of erosion during the annual rains.

1

1

3

3

1

1

1

1