3

3

3

3

5

5

7

7

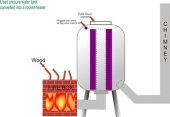

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

1

1

1

1

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

2

2

1

1

Invasive plants are Earth's way of insisting we notice her medicines. Stephen Herrod Buhner

Everyone learns what works by learning what doesn't work. Stephen Herrod Buhner

1

1

Fox James wrote:Eugene, you may have some points but, at the end of the day the owner in question seems delighted with his stove!

1

1

2

2

For all your Montana Masonry Heater parts (also known as) Rocket Mass heater parts.

Visit me at

dragontechrmh.com Once you go brick you will never go back!

| I agree. Here's the link: http://stoves2.com |