1

1

Those who hammer their swords into plows will plow for those who don't!

2

2

"You must be the change you want to see in the world." "First they ignore you, then they laugh at you, then they fight you, then you win." --Mahatma Gandhi

"Preach the Gospel always, and if necessary, use words." --Francis of Assisi.

"Family farms work when the whole family works the farm." -- Adam Klaus

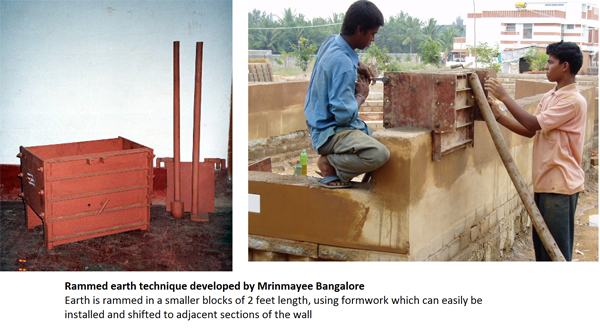

R Scott wrote:It is called slipforming.

Those who hammer their swords into plows will plow for those who don't!

2

2

1

1

http://www.cloud9farms.com/ - Southern Colorado - Zone 5 (-19*f) - 5300ft elevation - 12in rainfall plus irrigation rights

Dairy cows, "hair" sheep, Kune Kune pigs, chickens, guineas and turkeys

2

2

1

1

Dale Hodgins wrote:I love the simplicity of this slip form. He foot stomps only. If more braces were used, a similar form could be rammed with a tamper. Steel pipe could be used as well. Cob could be formed like this.

This is in the Indian Himalayas. The man doing the work looks Tibetan. The film people are speaking slowly to him, so I assume that they are from further South and they speak different languages. ---

----------------------------------------------------------------------------------------------

I've asked one of our members for a translation of anything regarding this process. It's late at night on the west coast, so I don't expect she will see this tonight.

"You must be the change you want to see in the world." "First they ignore you, then they laugh at you, then they fight you, then you win." --Mahatma Gandhi

"Preach the Gospel always, and if necessary, use words." --Francis of Assisi.

"Family farms work when the whole family works the farm." -- Adam Klaus

3

3

Works at a residential alternative high school in the Himalayas SECMOL.org . "Back home" is Cape Cod, E Coast USA.

3

3

Works at a residential alternative high school in the Himalayas SECMOL.org . "Back home" is Cape Cod, E Coast USA.

3

3

Works at a residential alternative high school in the Himalayas SECMOL.org . "Back home" is Cape Cod, E Coast USA.

3

3

![Filename: Cavity-wall.jpg

Description: Cavity wall to be filled with clean garbage for insulation [Thumbnail for Cavity-wall.jpg]](/t/33925/a/15539/Cavity-wall.jpg)

Works at a residential alternative high school in the Himalayas SECMOL.org . "Back home" is Cape Cod, E Coast USA.

3

3

Works at a residential alternative high school in the Himalayas SECMOL.org . "Back home" is Cape Cod, E Coast USA.

2

2

Works at a residential alternative high school in the Himalayas SECMOL.org . "Back home" is Cape Cod, E Coast USA.

2

2

1

1

Works at a residential alternative high school in the Himalayas SECMOL.org . "Back home" is Cape Cod, E Coast USA.

3

3

Buy Our Book! Food Web: Concept - Raising Food the Right Way. Learn make more food with less inputs

Off Grid Homesteading - latest updates and projects from our off grid homestead

|

Spare the rod, spoil the child. Here, use this tiny ad named Rod:

Looking for cold-climate growers to join a GOOF livestream panel (Missoula)

https://permies.com/t/369111/cold-climate-growers-join-GOOF

|