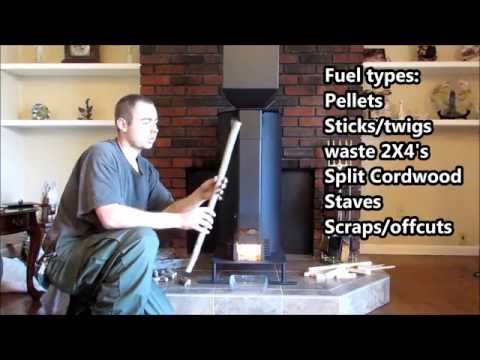

UL-1482 Tested Rocket Heater and Gravity Fed Pellet Burning Rocket Heaters:

http://www.permies.com/t/54288/rocket-stoves/Building-code-compliant-prefabricated-rocket#446840

http://www.rocketheater.com/

3

3

Glenn Herbert wrote:First off, I'm glad you are doing well enough with your initial model to keep the business going. The more variety in available approaches, the better, and if someone can get a manufactured version when they would otherwise not be able or allowed to build their own, that just spreads the awareness of the technology.

I don't have a more informed opinion than anyone else on minimum refractory thickness, but I think a round riser would be more durable, and probably a bit more efficient. Also, it would obviously require less material for a given system size - not an unimportant point when making them commercially. I don't think you would actually need a really heavy outer shell for the riser, as that region after the combustion zone has historically been demonstrated to have conditions not conducive to corrosion.

A 6" size would likely be easier to make as a shippable unit, and small enough to more easily find installation locations. I might consider a 6" batch box, as that is supposed to have the heating power of an 8" J-tube, so could power a larger system while keeping the smaller combustion unit size. What are you thinking with regard to connecting your units to owner-supplied mass storage? I would think there could be a way for your manufactured and listed product to have thermal mass put next to or around the exhaust without voiding the listing... is this true? If the unit you test and sell is designed to shed enough heat in itself that your exhaust could safely go up the chimney even if someone foolishly insulated the duct run (!), any kind of thermal mass would not negatively impact the assembly's safety.

A catalytic combustor would be irrelevant to a properly functioning RMH, so I don't see any advantage to including that kind of thing. I would even consider a sales point like "total efficiency and pollution reduction without a catalytic unit to worry about".

There is a thread here about inexpensive ceramic fiber heat risers, and that might be a technology for you to look at; it would reduce shipping weight, not require as much protection from shipping damage/cracking, and contain the insulation in a slender package, which could probably be fitted inside a metal shell for shipping and moving safety.

UL-1482 Tested Rocket Heater and Gravity Fed Pellet Burning Rocket Heaters:

http://www.permies.com/t/54288/rocket-stoves/Building-code-compliant-prefabricated-rocket#446840

http://www.rocketheater.com/

Glenn Herbert wrote:It is 1" thick, and the riser sections the thread discusses are 6" ID and 24" long. This thickness of this material is generally considered sufficient by itself for heat riser insulation.

UL-1482 Tested Rocket Heater and Gravity Fed Pellet Burning Rocket Heaters:

http://www.permies.com/t/54288/rocket-stoves/Building-code-compliant-prefabricated-rocket#446840

http://www.rocketheater.com/

1

1

I believe I read that the vacuum formed ceramic heat risers were 2" thick, so a 6" ID would be 8" OD.Glenn Herbert wrote:It is 1" thick, and the riser sections the thread discusses are 6" ID and 24" long. This thickness of this material is generally considered sufficient by itself for heat riser insulation.

I think the thread gives enough information for you to contact the manufacturer for detailed specs.

jonathan kedzierski wrote:

I believe I read that the vacuum formed ceramic heat risers were 2" thick, so a 6" ID would be 8" OD.Glenn Herbert wrote:It is 1" thick, and the riser sections the thread discusses are 6" ID and 24" long. This thickness of this material is generally considered sufficient by itself for heat riser insulation.

I think the thread gives enough information for you to contact the manufacturer for detailed specs.

UL-1482 Tested Rocket Heater and Gravity Fed Pellet Burning Rocket Heaters:

http://www.permies.com/t/54288/rocket-stoves/Building-code-compliant-prefabricated-rocket#446840

http://www.rocketheater.com/

2

2

"open's mouth and inserts foot" 😃Sky Huddleston wrote:

jonathan kedzierski wrote:

I believe I read that the vacuum formed ceramic heat risers were 2" thick, so a 6" ID would be 8" OD.Glenn Herbert wrote:It is 1" thick, and the riser sections the thread discusses are 6" ID and 24" long. This thickness of this material is generally considered sufficient by itself for heat riser insulation.

I think the thread gives enough information for you to contact the manufacturer for detailed specs.

If its 6" ID and 8" OD then its one inch thick.

2

2

John Daley Bendigo, Australia The Enemy of progress is the hope of a perfect plan

Benefits of rainfall collection https://permies.com/t/88043/benefits-rainfall-collection

GOOD DEBT/ BAD DEBT https://permies.com/t/179218/mortgages-good-debt-bad-debt

1

1

John C Daley wrote:How is this project coming along now?

UL-1482 Tested Rocket Heater and Gravity Fed Pellet Burning Rocket Heaters:

http://www.permies.com/t/54288/rocket-stoves/Building-code-compliant-prefabricated-rocket#446840

http://www.rocketheater.com/

|

I wish I could be half as happy as this tiny ad!

Play Your Way to a Sustainable Lifestyle: Uncover Permaculture Principles with Each Card

https://gardener-gift.com/

|