I'm rather pleased that you would be surprised at a gaff on my part.

I count you as an accomplished maker, so I'm glad you expect better of me!

The different rates of flow and therefor heat transfer are necessary if I am to store heat till it is needed.

The pumped loop is so the storage tanks can capture BTUs as quickly as they are produced by a batch box rocket.

The thermal siphon exists so the forced air system can extract these BTUs as needed.

This line of reasoning leads me to conclude that 3 or 4 water heaters isn't enough storage.

I might in fact do the math but I'm pretty sure it will not be enough to make any significant impact on my heating bills.

A bigger tank would seem to be in order.

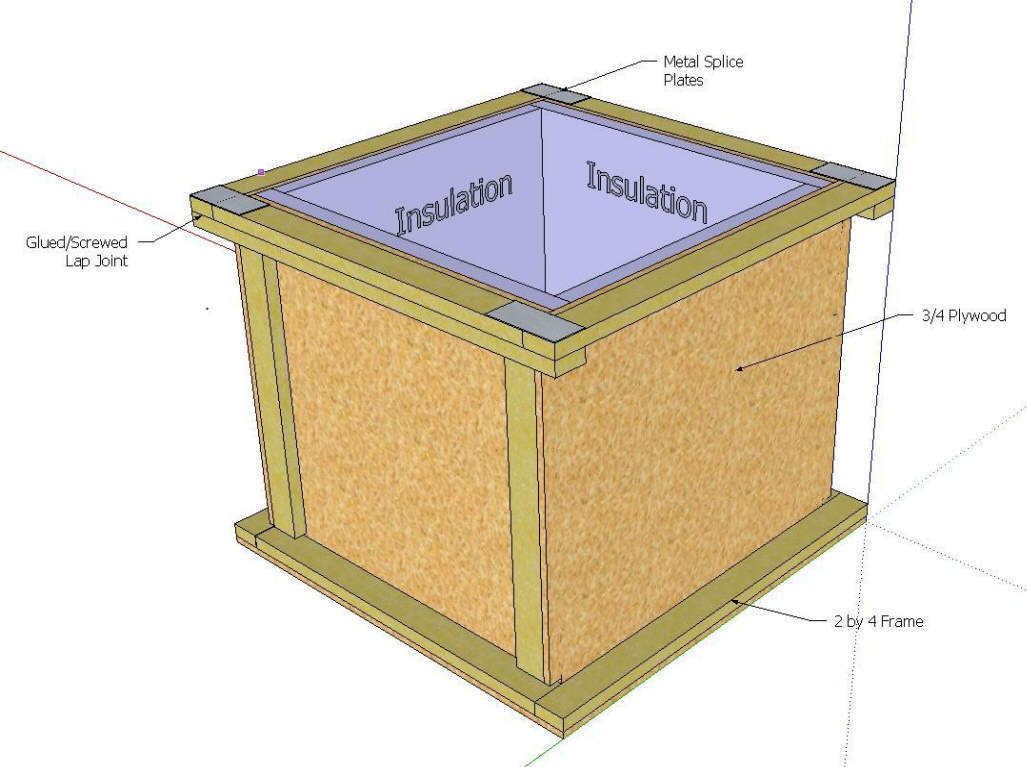

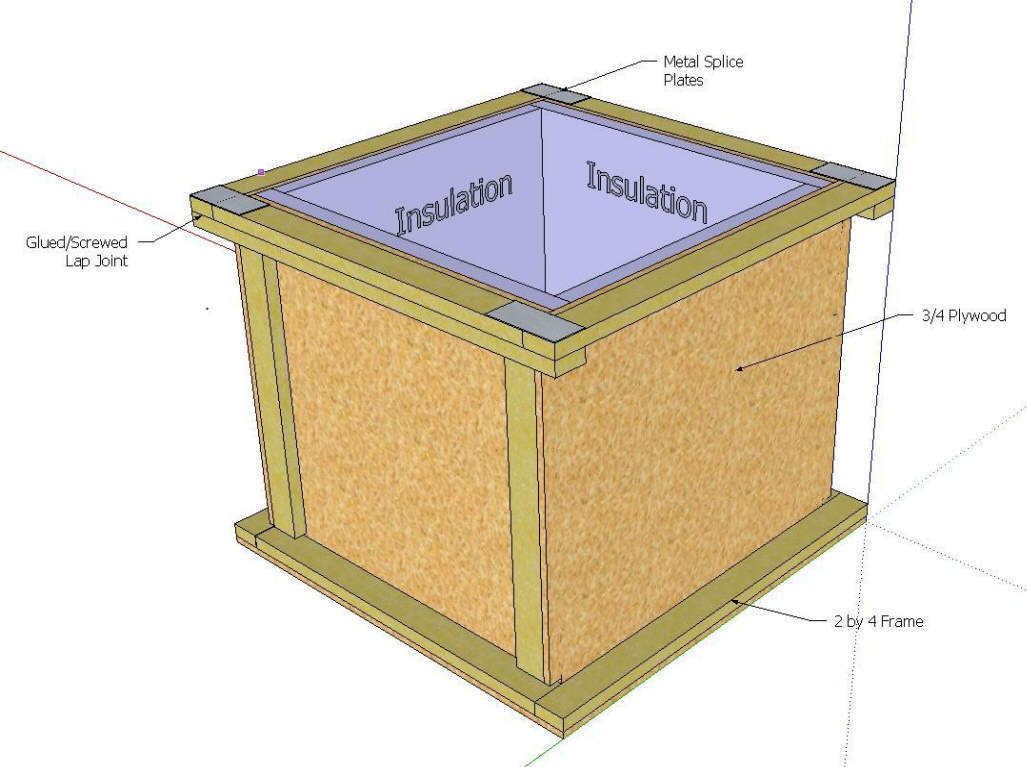

Build It Solar has a nice build:

It should be within my budget and skill level to build.

An in-line pump drawing water from the depths of the storage tank,would push the hottest water out of the top of the boiler tank.

The storage tank might make for a good bed platform, or seed starting bench.

A 4' x 8' x 2' tank would hold more than 470 gallons, and it would be great place to put The DHW heat exchanger.

Two 4' square 2" high tanks might be better for strength.

A defunct water heater, stripped of insulation and immersed in the storage tank would mean many gallons of preheated water.

I would want a line to the the city water supply , with a float valve,to ensure the storage tank was never dry, so adding the preheating loop wouldn't add much in the way of pipe used.

Another design element troubles me.

To avoid the hazards of steam, my plan has been to keep the boiler tank out of the hottest exhaust.

Instead, I was going place the tank in a bell, and allow the exhaust to surround the tank.

The tank is roughly cylindrical and the poor surface area to volume ratio could hinder heat exchange.

Further, the boiler shed is is exactly the place we want to remove the heat from, so more time spent hanging out in the bell is a drag on performance.

I'm wondering if a small stainless steel tank located right over the riser might be a better choice,even if it means downsizing the batch box rocket.

At that position, the tank will always be exposed to the highest heat in the system, even if the fire is out, and smaller tank would have a better surface area to volume ratio.

But I will be courting boom-squish.

How many boiler pressure release valves could I practically employ, I wonder?

Would 1/2 black iron survive as supply and return lines to a tank in that position?

Could I adapt some stainless steel gas line to do the job?

One last musing for now.

Would a simple TLUD be a better choice for my heat source?

I haven't been able to get my 4 gallon stock pot TLUD to reliably run on anything but wood pellets, but boy does it run!

I suspect it's the regular size and dryness of the pellets that make them ideal.

To scale up and not pay for the privilege of burning biomass, I'm thinking

pallets are my best bet.

Even old,out in the weather pallets burn pretty well.

A bundle of pallet wood vertical in a TLUD, might have the combination of regular shape dryness to burn well.

Another thought, pallet wood strapped into a Swedish Torch configuration.

As always, the value of scavenged biomass is diminished by how much you must process it to use it.

2

2

2

2

2

2

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

4

4

1

1